High-thermal conductivity polyamide composite material and preparation method thereof

A technology of composite materials and heat-conducting materials, which is applied in the field of high-thermal-conductivity polyamide composite materials and their preparation, can solve the problems of low thermal conductivity, reduced mechanical properties, and high cost, and achieve high thermal conductivity, reduce dosage, and prevent hydrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

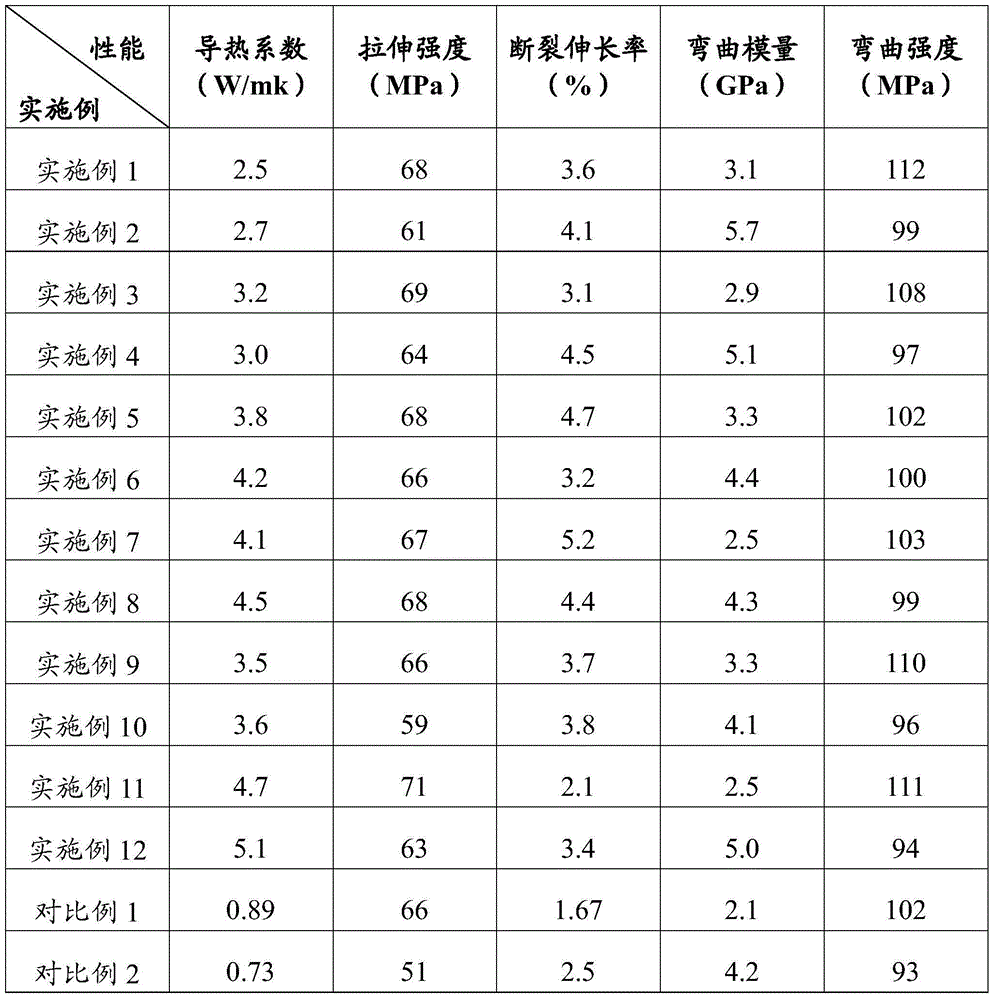

Examples

preparation example Construction

[0033] Correspondingly, on the basis of the high thermal conductivity polyamide composite material provided above, the embodiment of the present invention also provides a material preparation method of the high thermal conductivity polyamide composite material. The method comprises the steps of:

[0034] Step S01. Melt-blending the dispersant and the heat-conducting material to prepare the heat-conducting masterbatch:

[0035] Melt-blending the thermally conductive material and the dispersant to form a thermally conductive masterbatch; wherein, the dispersant accounts for 30-40% of the total mass of the thermally conductive material and the dispersant; the thermally conductive material includes a mass ratio of (50 -60): (5-10): (5-10): (5-10): (1-5) nano aluminum nitride, micron aluminum nitride, micron boron nitride, micron silicon nitride and carbon-based material mixtures;

[0036] Step S02. Melting and extruding the thermally conductive masterbatch and polyamide resin: ...

Embodiment 1

[0050] A high thermal conductivity polyamide composite material and a preparation method thereof. The preparation method of the high thermal conductivity polyamide composite material is as follows:

[0051] Mix 600 grams of nano-aluminum nitride, 50 grams of micro-aluminum nitride, 50 grams of micro-boron nitride, 50 grams of micro-silicon nitride, and 10 grams of multi-walled carbon nanotubes at room temperature for 5 minutes at high speed, and then add molten 300 grams of EBS was mixed mechanically for 10 minutes at a rotational speed of 1000 rpm, and then the material was cooled and pulverized into granules to obtain a thermally conductive filler masterbatch. After mixing the obtained thermally conductive filler masterbatch with 1000g of nylon 6, extrude and granulate in a twin-screw extruder, the aspect ratio of the extruder is 44:1, and the processing temperature is 100-280°C.

Embodiment 2

[0053] A high thermal conductivity polyamide composite material and a preparation method thereof. The preparation method of the high thermal conductivity polyamide composite material is as follows:

[0054] Mix 600 grams of nano-aluminum nitride, 50 grams of micro-aluminum nitride, 50 grams of micro-boron nitride, 50 grams of micro-silicon nitride, and 10 grams of multi-walled carbon nanotubes at room temperature for 5 minutes at high speed, and then add molten 300 grams of EBS was mixed mechanically for 10 minutes at a rotational speed of 1000 rpm, and then the material was cooled and pulverized into granules to obtain a thermally conductive filler masterbatch. After mixing the obtained thermally conductive filler masterbatch with 1000g of nylon 66, extrude and pelletize in a twin-screw extruder, the aspect ratio of the extruder is 44:1, and the processing temperature is 100-330°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com