ErFeV magnetic wave-absorbing material and preparation method thereof

A magnetic wave absorbing, er10.5fe89.5 technology, applied in the field of magnetic microwave absorbing materials, can solve the problems of no saturation magnetization and magnetic permeability, restricting the application of materials, failing to achieve light weight and strong absorption, etc., to achieve good Microwave absorption characteristics, low cost, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

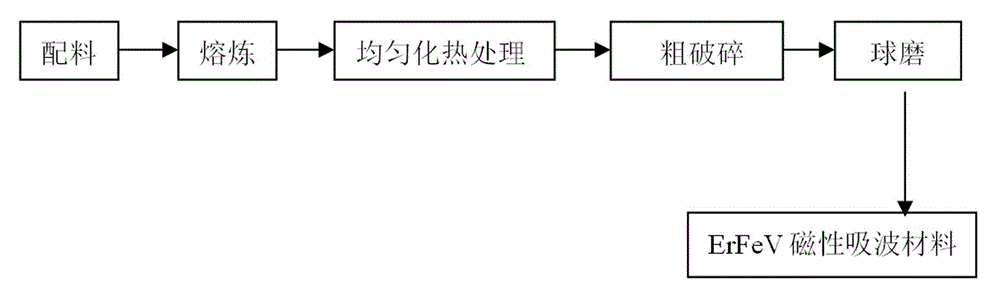

Method used

Image

Examples

Embodiment 1

[0027] Preparation of Er 10.5 Fe 89.5 (Atomic percentage) concrete implementation steps:

[0028] 1) Er and Fe metals with a purity ≥ 99.90%, according to Er 10.5 Fe 89.5 The stoichiometric ratio of the atomic percentage of the ingredients;

[0029] 2) Smelting in a standard electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, repeatedly turning and melting for 3 to 4 times;

[0030] 3) Keep the smelted ingot under vacuum protection at a temperature of 700°C for 7 days and then quench it in ice water;

[0031] 4) Mechanically crush the obtained alloy ingot to obtain alloy coarse powder, then put stainless steel balls and coarse powder into a stainless steel tank at a mass ratio of 15:1, add gasoline as a protective agent, and use a QM-lSP planetary ball mill to grind the alloy The coarse powder ball milled for 60 hours, and the ball mill rotating speed was 350 rpm;

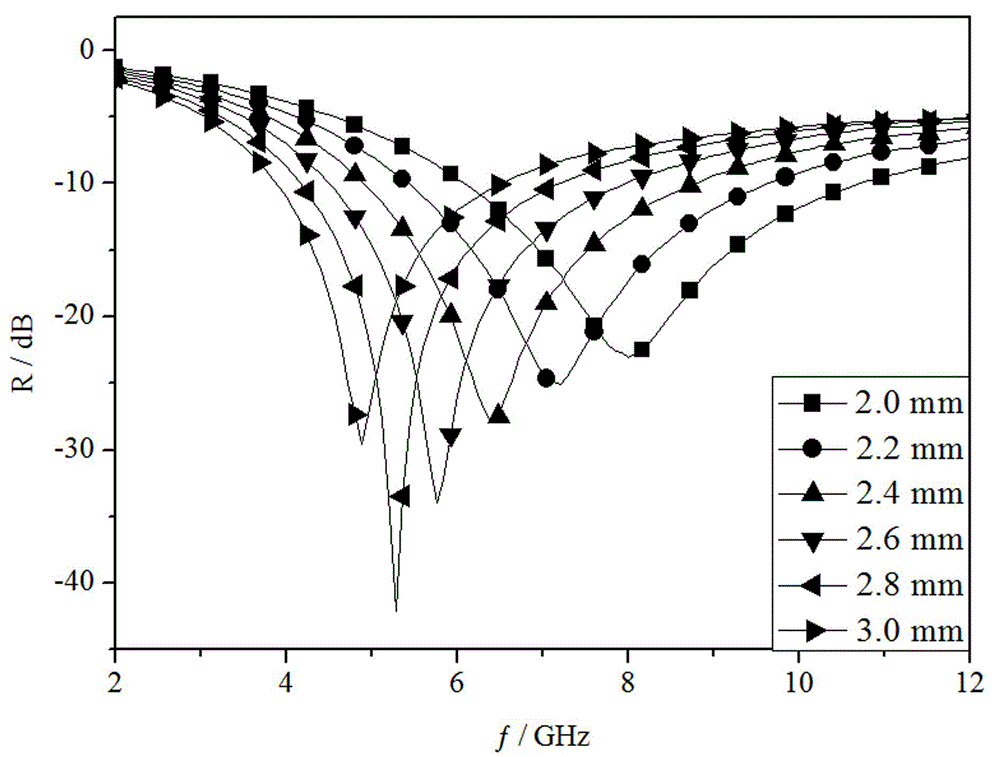

[0032] Product test: mix according to the...

Embodiment 2

[0038] Preparation of Er 10.5 Fe 87.5 V 2 The specific implementation steps of (atomic percentage) are:

[0039] 1) Er, Fe, V metals with a purity ≥ 99.90%, according to Er 10.5 Fe 87.5 V 2 Stoichiometric ratio ingredients of molecular formula;

[0040] 2) Smelting in a standard electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, repeatedly turning and melting for 3 to 4 times;

[0041] 3) Keep the smelted ingot under vacuum protection at a temperature of 700°C for 7 days and then quench it in ice water;

[0042] 4) The obtained alloy ingot is mechanically crushed to obtain coarse alloy powder, and then the stainless steel ball and the coarse powder are

[0043] Put the powder into a stainless steel tank at a mass ratio of 15:1, add gasoline as a protective agent, and use a QM-lSP planetary ball mill to mill the alloy coarse powder for 60 hours at a speed of 350 rpm.

[0044] Product testing: mix according ...

Embodiment 3

[0048] Preparation of Er 10.5 Fe 85.5 V 4 The specific implementation steps of (atomic percentage) are:

[0049] 1) Er, Fe, V metals with a purity ≥ 99.90%, according to Er 10.5 Fe 85.5 V 4 Stoichiometric ratio ingredients of molecular formula;

[0050] 2) Smelting in a standard electric arc furnace under the protection of argon, in order to ensure that the composition of the alloy is uniform, repeatedly turning and melting for 3 to 4 times;

[0051] 3) Keep the smelted ingot under vacuum protection at a temperature of 700°C for 7 days and then quench it in ice water;

[0052] 4) Mechanically crush the obtained alloy ingot to obtain alloy coarse powder, then put stainless steel balls and coarse powder into a stainless steel tank at a mass ratio of 15:1, add gasoline as a protective agent, and use a QM-lSP planetary ball mill to grind the alloy The coarse powder ball milled for 60 hours, and the ball mill rotating speed was 350 rpm;

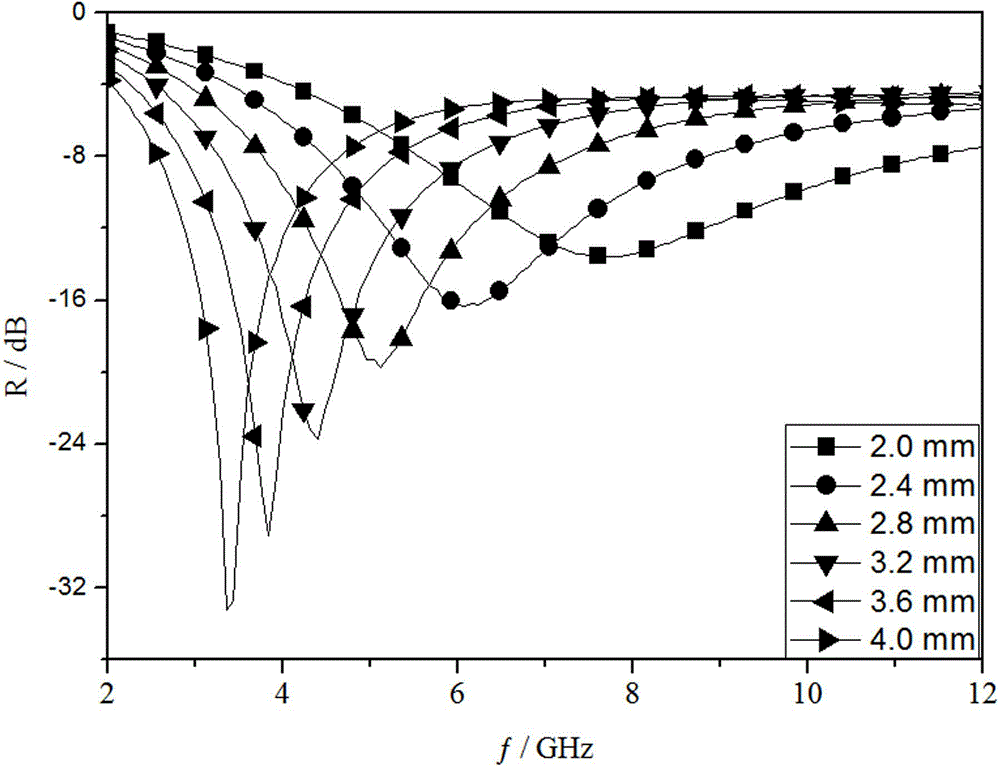

[0053] Product testing: Alloy powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com