Cobalt-antimonide-base thermoelectric film and preparation method thereof

A thermoelectric thin film, cobalt antimonide-based technology, applied in the field of cobalt antimonide-based thermoelectric thin film and its preparation, can solve the problems of poor controllability, low efficiency, cumbersome process, etc., achieve simplified preparation process, reduce cumbersome process, controllable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Using In as the dopant material (A), firstly, CoSb 3 and In targets are respectively fixed on the two-station target racks of the sputtering apparatus (multi-station sputtering system) to be sputtered; with polyimide (PI) as the substrate (insulating substrate), the substrate Placed in a container, ultrasonically cleaned with acetone, alcohol and deionized water in sequence; the background vacuum of the sputtering system was pumped to 6.0×10 -4 Pa, the inlet flow rate is 40 sccmAr gas (high purity), and the working pressure is controlled at 3.0×10 -1 Pa: The ion beam with ion source energy lower than 1KeV is used to bombard the surface of the substrate to further remove the impurity molecules adsorbed on the surface of the substrate;

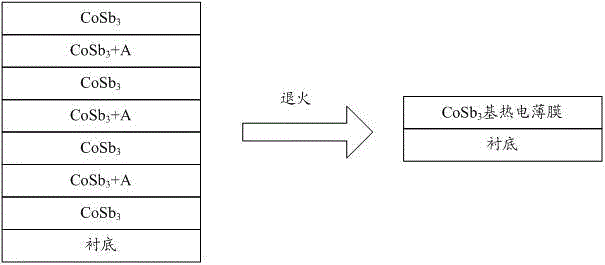

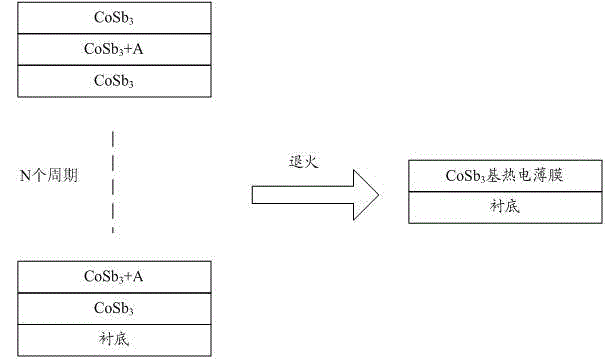

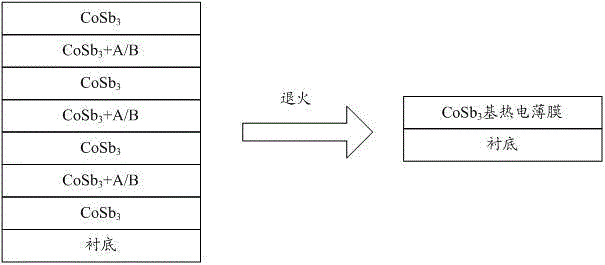

[0051] Such as figure 1 As shown, in the first embodiment, firstly, the sputtering method is used to plate CoSb on the substrate 3 Thermoelectric thin film, the total sputtering time is 60 min, when CoSb 3 When sputtering to 15 min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com