Liquid-state heavy metal oxygen concentration control solid-liquid exchange reaction apparatus under flowing working condition

A liquid heavy metal and liquid metal technology, which is used in reactors, nuclear reactor monitoring, nuclear engineering, etc., can solve the problems of PbO particle dissolution and deposition function failure, and achieve the effect of easy implementation and operation, and simple overall structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

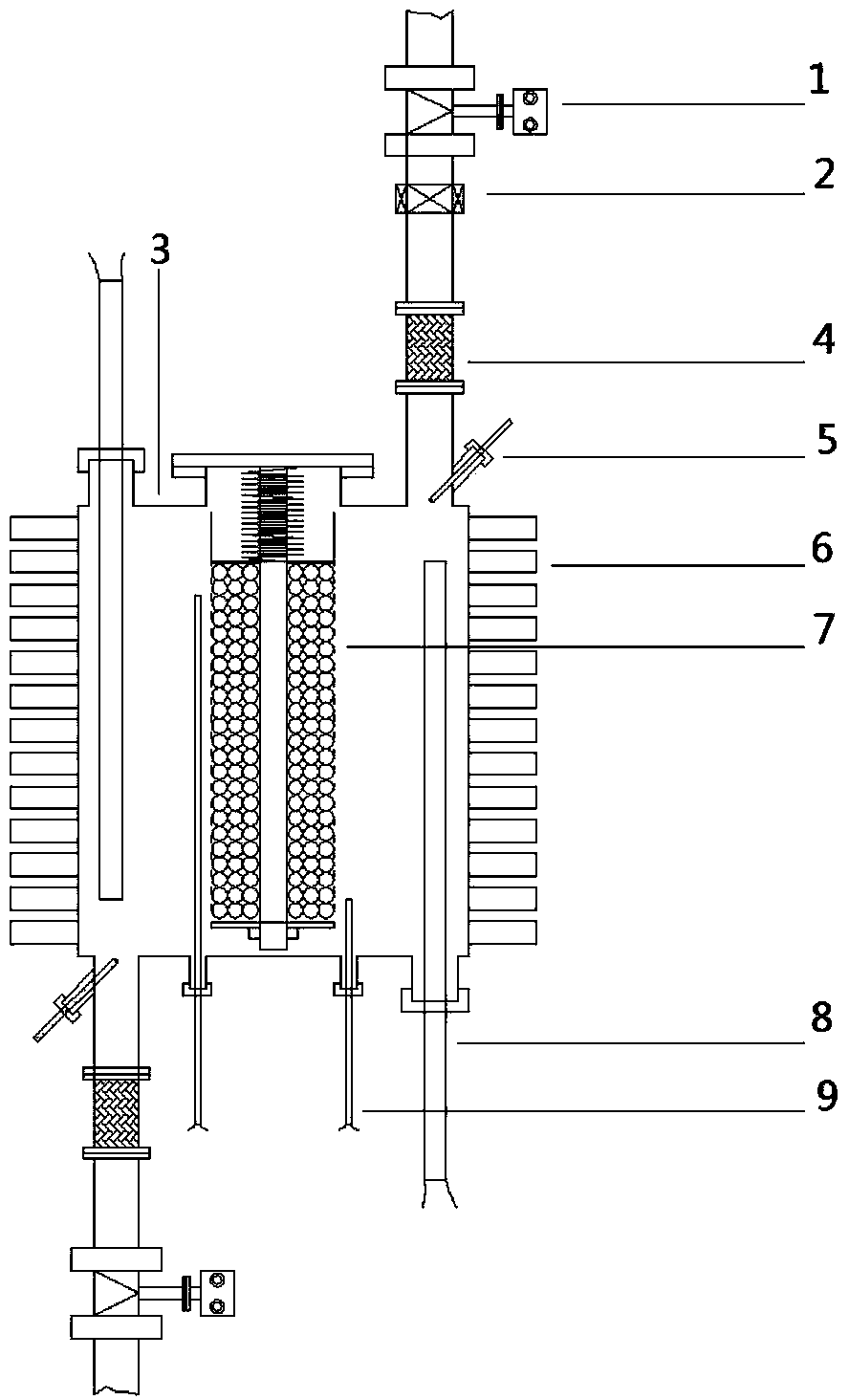

[0013] Such as figure 1 As shown, a liquid heavy metal oxygen concentration control solid-liquid exchange reaction device under flowing conditions, the device includes: liquid metal valve 1, liquid metal flow meter 2, reaction vessel 3, screen filter 4, oxygen measuring instrument 5 , Air cooling device 6, mass exchanger 7, built-in heating rod 8 and built-in thermocouple 9. First, the whole device is preheated to 300°C through the built-in heating rod 8 and the heating cable around the reaction vessel 3, and kept warm for 12 hours, then slowly inject lead and bismuth into the experimental system and the device; the signal from the oxygen sensor in the experimental system shows that the lead The oxygen concentration of bismuth is too low to feed back to the control system, increase the heating power of the built-in heating rod 8 and increase t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com