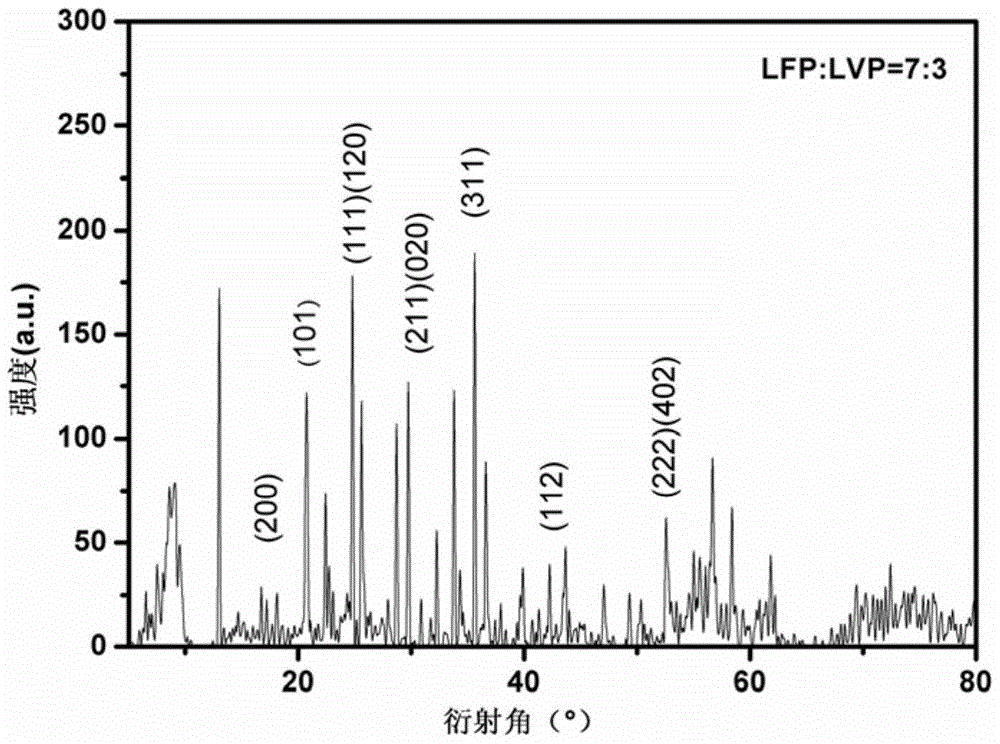

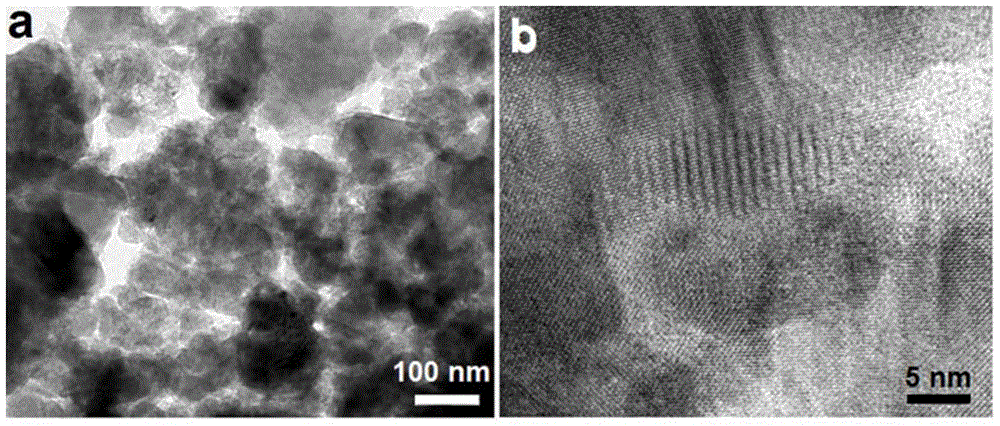

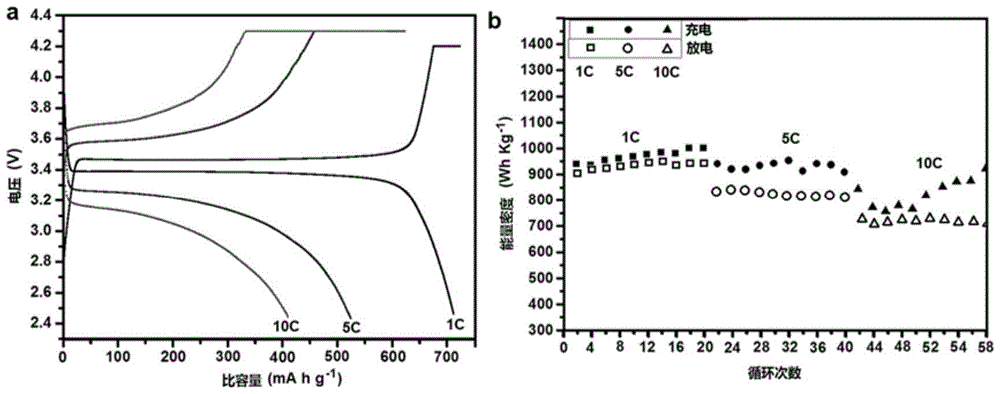

Preparation method of lithium iron phosphate·lithium vanadium phosphate/carbon in-situ composite cathode material

A positive electrode material and in-situ recombination technology, applied in phosphorus compounds, chemical instruments and methods, battery electrodes, etc., can solve problems such as low electronic conductivity and ion diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of LiFePO 4 ·Li 3 V 2 (PO 4 ) 3 / C in-situ composite cathode material preparation method, the steps are as follows:

[0046] (1) Dissolve ferric chloride in deionized water to prepare a ferric ion solution with a molar concentration of 0.5 mol / L and record it as solution A;

[0047] Ammonium metavanadate was added to the 0.3mol / L oxalic acid solution, heated and stirred at 70°C and 250r / min for 1 hour to prepare a vanadium ion solution with a molar concentration of 0.5mol / L, which was recorded as solution B;

[0048] Put 2g of activated yeast in 5ml of deionized water to prepare a yeast suspension with a mass concentration of 40%, which is recorded as solution C;

[0049] The activated yeast is prepared by the following method:

[0050] Inoculate high-active dry yeast into a glucose solution with a mass concentration of 4% at a mass ratio of 2%, activate and cultivate at 35°C for 0.5h, filter the precipitate, and wash the precipitate twice to obtain the activated yeast;

[...

Embodiment 2

[0057] A kind of LiFePO 4 ·Li 3 V 2 (PO 4 ) 3 / C in-situ composite cathode material preparation method, the steps are as follows:

[0058] (1) Dissolve ferric chloride in deionized water to prepare an iron ion solution with a molar concentration of 0.8 mol / L, and record it as solution A;

[0059] Ammonium metavanadate was added to 0.4mol / L oxalic acid solution, heated and stirred at 70°C and 200r / min for 1.5h to prepare a vanadium ion solution with a molar concentration of 0.8mol / L, which was recorded as solution B;

[0060] Place 1g of activated yeast in 5ml of deionized water to prepare a yeast suspension with a mass concentration of 20%, which is recorded as solution C;

[0061] The activated yeast is prepared by the following method:

[0062] Inoculate the highly active dry yeast in a glucose solution with a mass concentration of 2% at a mass ratio of 1%, activate and cultivate at 30°C for 1 hour, filter the precipitate, and wash the precipitate 3 times to obtain the activated yeast...

Embodiment 3

[0069] A LiFePO 4 ·Li 3 V 2 (PO 4 ) 3 / C in-situ composite cathode material preparation method, the steps are as follows:

[0070] (1) Dissolve ferric chloride in deionized water to prepare a ferric ion solution with a molar concentration of 0.3 mol / L and record it as solution A;

[0071] Ammonium metavanadate was added to the 0.5mol / L oxalic acid solution, heated and stirred at 70°C and 300r / min for 2h to prepare a vanadium ion solution with a molar concentration of 0.3mol / L, which was recorded as solution B;

[0072] Place 1.5g of activated yeast in 5ml of deionized water to prepare a yeast suspension with a mass concentration of 30%, which is recorded as solution C;

[0073] The activated yeast is prepared by the following method:

[0074] Inoculate high-active dry yeast in a glucose solution with a mass concentration of 3% at a mass ratio of 1.5%, activate and cultivate at 37°C for 0.5h, filter the precipitate, and wash the precipitate twice to obtain the activated yeast;

[0075] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com