Hollow spherical LiTiO2 material and preparation method thereof

A spherical, hollow technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of negative impact on electrochemical performance, difficult control of powder morphology, harsh reaction conditions, etc., to achieve environmentally friendly, good Electrochemical performance, effect of moderate conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A hollow spherical LiTiO 2 The preparation method of material comprises the following steps:

[0029] (1) Prepare 30 ml of lithium oxalate solution with a concentration of 2.2 moles per liter, add titanium dioxide so that the molar ratio of lithium to titanium is 5:1, and stir the mixed solution at 40°C for 60 minutes to obtain a microwave hydrothermal reaction precursor liquid;

[0030] (2) Transfer the above mixed solution to a polytetrafluoroethylene-lined microwave hydrothermal reaction kettle, microwave hydrothermal reaction for 60 minutes under the conditions of 600 watts and 160 ° C, and the filling ratio of the microwave hydrothermal reaction kettle is 50% ;

[0031] (3) Cool to room temperature after the reaction, and then centrifuge to separate the precipitate, which is washed with deionized water and absolute ethanol respectively. The precipitate was dried at 60 °C for 1 h to obtain hollow spherical LiTiO 2 Material.

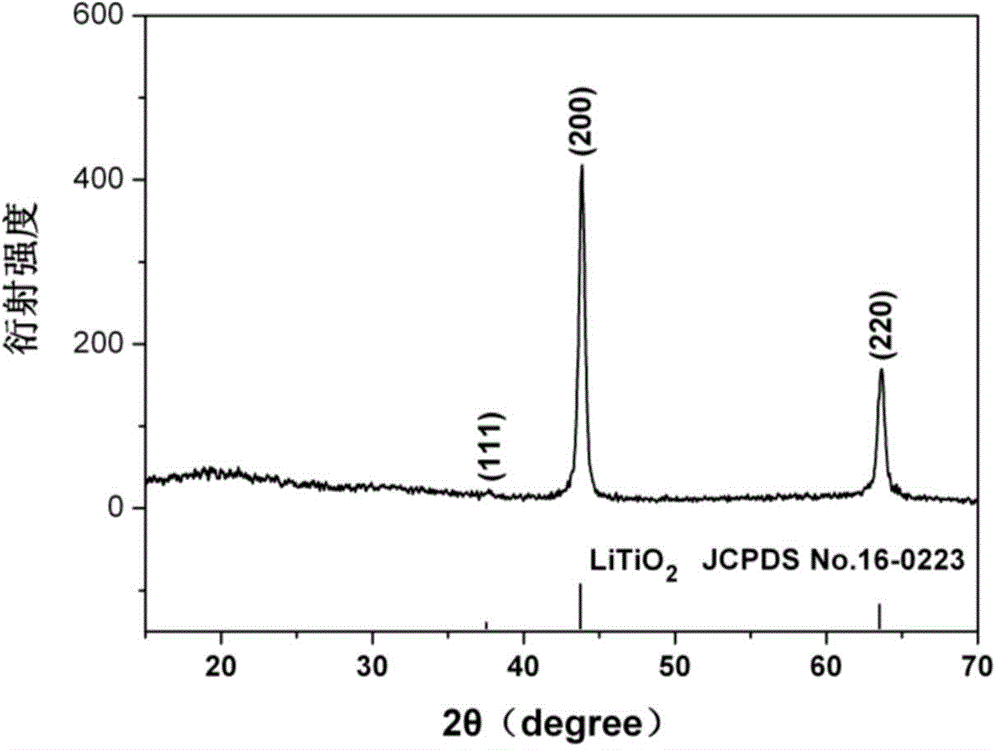

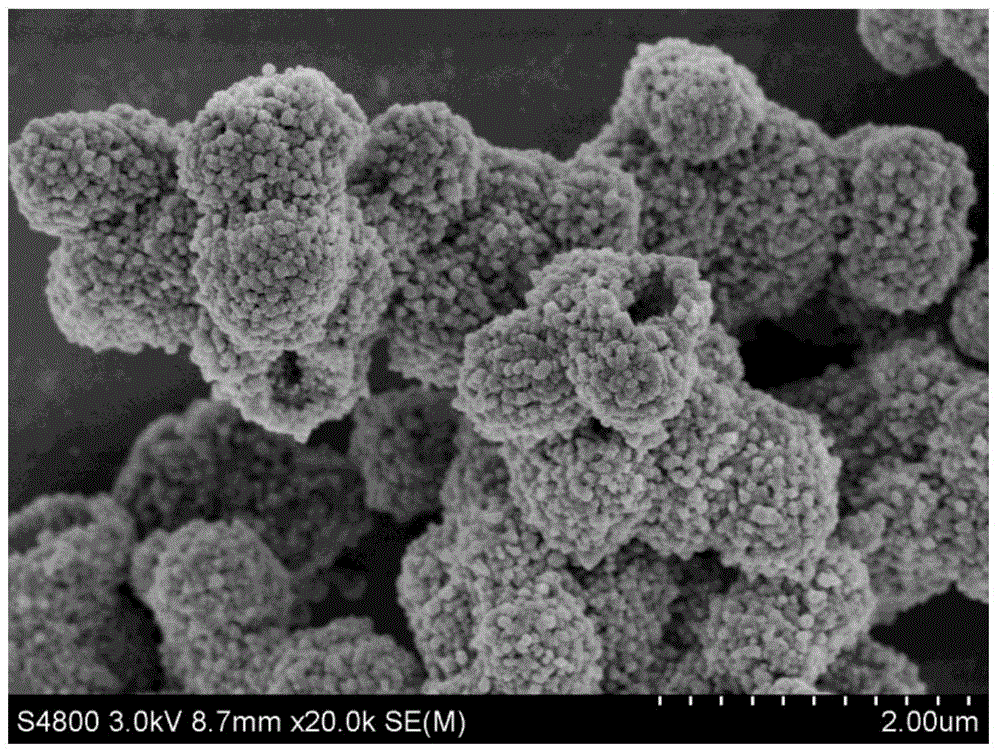

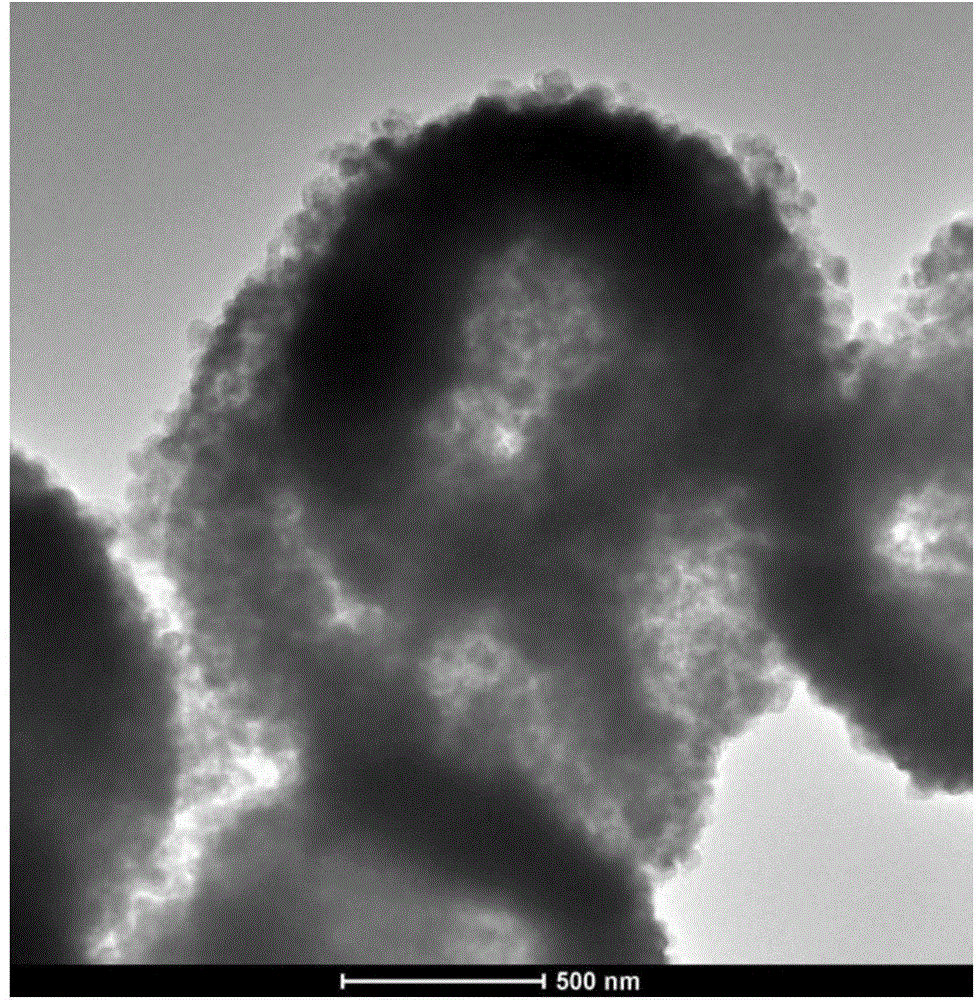

[0032] The hollow spherical LiTiO o...

Embodiment 2

[0035] A hollow spherical LiTiO 2 The preparation method of material comprises the following steps:

[0036] (1) Prepare 40 ml of lithium hydroxide solution with a concentration of 2.0 moles per liter, add isopropyl titanate so that the molar ratio of lithium to titanium is 10:1, stir the mixed solution at 60°C for 80 minutes with magnetic force, and obtain Microwave hydrothermal reaction precursor;

[0037] (2) Transfer the above mixed solution to a polytetrafluoroethylene-lined microwave hydrothermal reaction kettle, and microwave hydrothermal reaction under the conditions of 800 watts and 140°C for 70 minutes, and the filling ratio of the microwave hydrothermal reaction kettle is 60%. ;

[0038] (3) Cool to room temperature after the reaction, and then centrifuge to separate the precipitate, which is washed with deionized water and absolute ethanol respectively. The precipitate was dried at 70 °C for 1 h to obtain hollow spherical LiTiO 2 Material.

[0039] The hollow ...

Embodiment 3

[0041] A hollow spherical LiTiO 2 The preparation method of material comprises the following steps:

[0042](1) Prepare 50 ml of lithium nitrate solution with a concentration of 1.8 moles per liter, add isopropyl titanate so that the molar ratio of lithium to titanium is 10:1, stir the mixed solution magnetically at 70°C for 40 minutes to obtain microwave Hydrothermal reaction precursor;

[0043] (2) Transfer the above mixed solution to a polytetrafluoroethylene-lined microwave hydrothermal reaction kettle, microwave hydrothermal reaction for 40 minutes under the conditions of 400 watts and 1680 ° C, and the filling ratio of the microwave hydrothermal reaction kettle is 30% ;

[0044] (3) Cool to room temperature after the reaction, and then centrifuge to separate the precipitate, which is washed with deionized water and absolute ethanol respectively. The precipitate was dried at 80 °C for 3 h to obtain hollow spherical LiTiO 2 Material.

[0045] The hollow spherical LiTi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com