Polylactic acid resin composition and molded body which is obtained using same

A technology of resin composition and polylactic acid resin, which is applied in the field of polylactic acid resin composition and molded products using it, can solve the problems of slow crystallization speed, etc., and achieve fast crystallization speed, improved crystallinity, and excellent crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

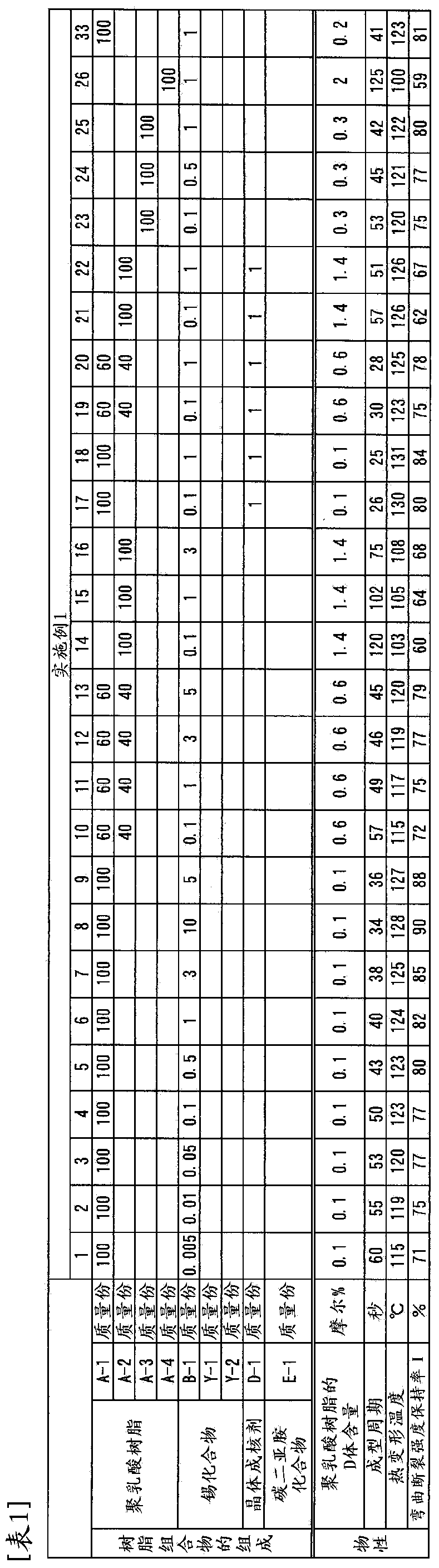

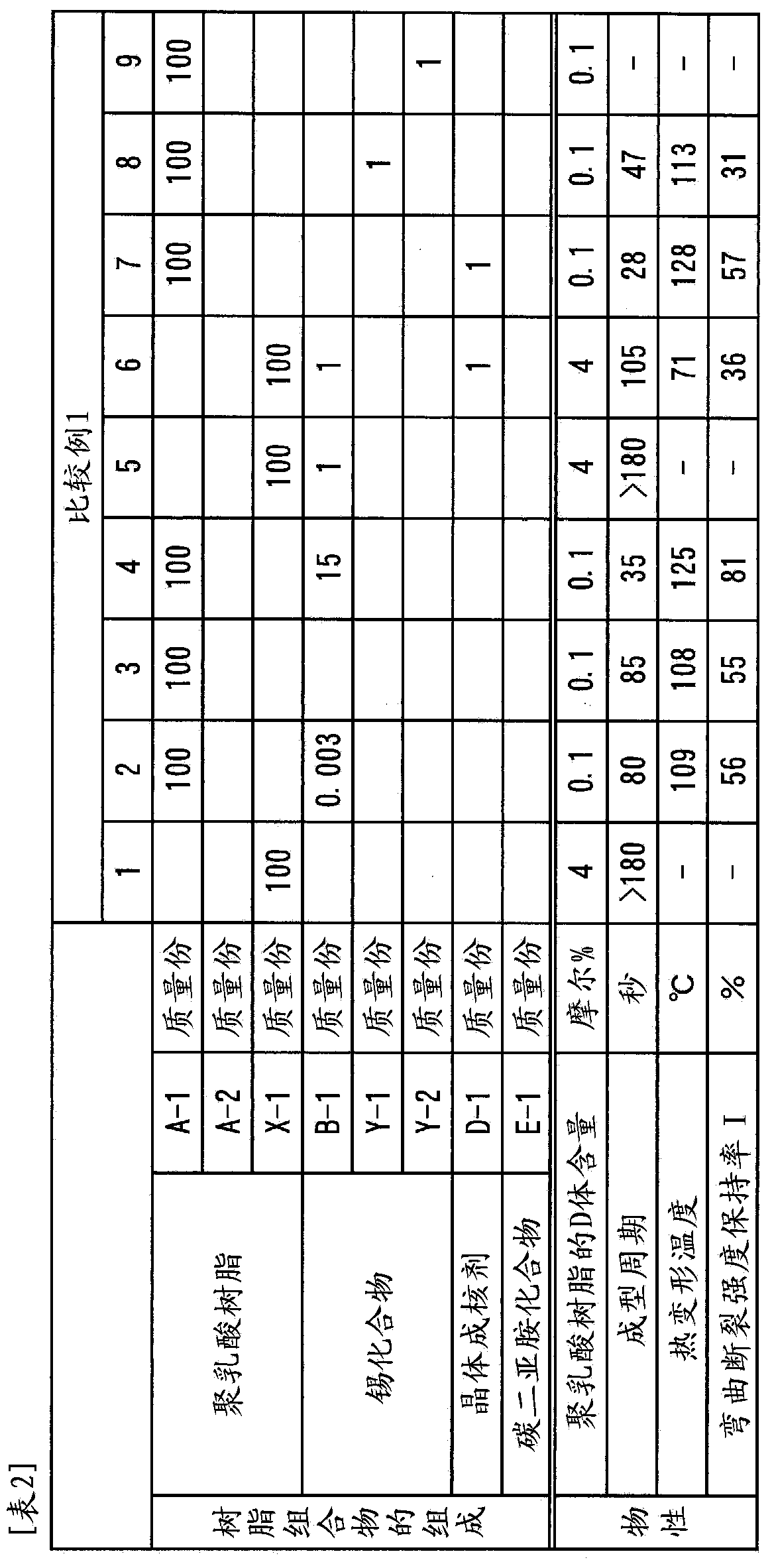

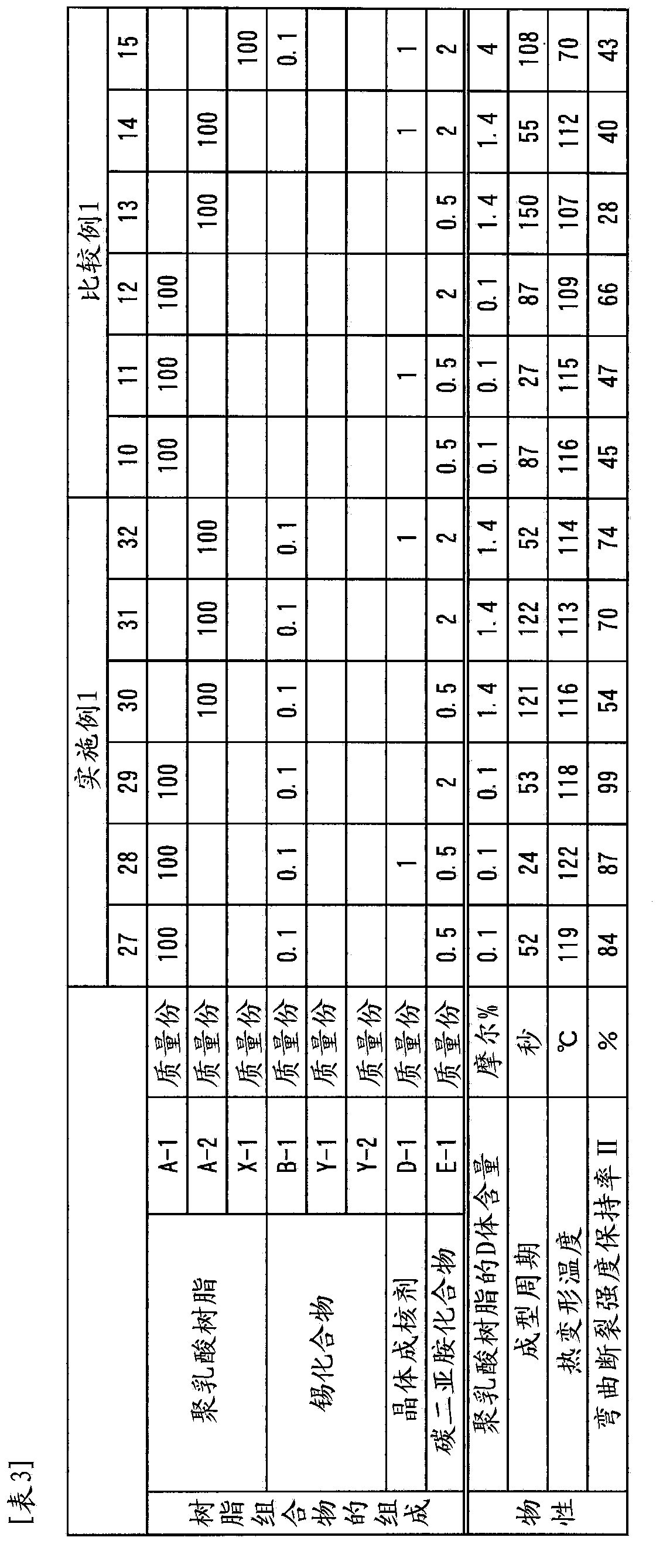

[0173] The resin compositions and molded articles of Nos. 1 to 32 of Example 1 shown in Tables 1 and 3 and Nos. 1 to 15 of Comparative Example 1 shown in Tables 2 and 3 were prepared as follows.

[0174] The various materials shown in Tables 1 to 3 were dry-blended at the ratios shown in Tables 1 to 3, and the resulting mixture was supplied to a twin-screw extruder (manufactured by Toshiba Machine Co., Ltd., TEM26SS). Melt-kneading was carried out under conditions of a rotation speed of 150 rpm and a discharge rate of 15 kg / h. The melt-kneaded product was extruded into strands through a die having three holes (0.4 mm in diameter), and cut to obtain pellets. The obtained pellets were dried at a temperature of 60° C. for 48 hours with a vacuum dryer (manufactured by Yamato Scientific, DP83) to obtain a pellet-shaped polylactic acid-based resin composition.

[0175] The obtained granular polylactic acid-based resin composition was injection-molded using an injection molding mach...

Embodiment 1

[0186] The polylactic acid-based resin composition of Example 1 had a short molding cycle to obtain a molded article, and the obtained molded article had a high heat distortion temperature and was excellent in heat resistance. In addition, the obtained molded article had a high retention rate of bending fracture strength and was excellent in wet heat durability.

[0187] The polylactic acid-based resin compositions of Nos. 17 to 22 in Example 1 were obtained by using tin oxide (B) and an organic crystal nucleating agent in combination. Therefore, the crystallinity is further improved, and the molding cycle becomes shorter. In addition, the heat resistance of the obtained molded article is also more excellent, and furthermore, the bending fracture strength retention rate is also high, and the wet heat durability is also improved.

[0188] The polylactic acid-type resin composition of No. 27-32 of Example 1 was obtained using tin oxide (B) and a carbodiimide compound together. ...

Embodiment 2 and comparative example 2

[0198] In this example, a resin composition containing a polylactic acid resin (A), tin oxide (B) and an impact modifier (C) is discussed.

[0199] The resin compositions and molded articles of Nos. 1 to 24 in Example 2 shown in Table 4 and Nos. 1 to 9 in Comparative Example 2 shown in Table 5 were produced in the following manner.

[0200] Various materials shown in Tables 4 to 5 were dry-blended at the ratios shown in Tables 4 to 5, and the same method as in Example 1 was used to obtain a granular polylactic acid resin composition.

[0201] The obtained granular polylactic acid resin composition is injection-molded by the same method as in Example 1, and made into a test piece (molded body) (80 mm in length, 10 mm in width, and 4 mm in thickness) for general physical property measurement based on ISO standards. ). This test piece was used for the measurement of the heat distortion temperature of the above (4), the measurement of the molding cycle of the above (5), and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com