A kind of preparation method of nano copper phosphide

A phosphide, nano-copper technology, applied in phosphide, nanotechnology, nanotechnology and other directions, can solve the problems of complex raw materials, cumbersome process, difficult to obtain nanometer size, etc., to achieve good particle uniformity, easy to obtain raw materials, good circulation The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] S1: red phosphorus powder obtained by ball milling red phosphorus with a purity of 98% for 6 hours, wherein the red phosphorus was purchased from Sinopharm. The copper mesh is also purchased from Sinopharm Group, the copper mesh is surface treated with hydrochloric acid, pickled to remove oxides on the surface of the copper mesh and make it clean, and the copper mesh and red phosphorus powder are sealed in a stainless steel tank filled with inert gas . Wherein, the red phosphorus mass is 0.1 to the copper mesh mass, and the volume of the stainless steel tank is 50ml.

[0033] S2: Sinter the stainless steel tank sealed with red phosphorus and copper mesh in step S1 in a muffle furnace, the sintering temperature is 450°C, the sintering time is 1h, and Cu with a particle size of about 120nm is obtained. 3 p.

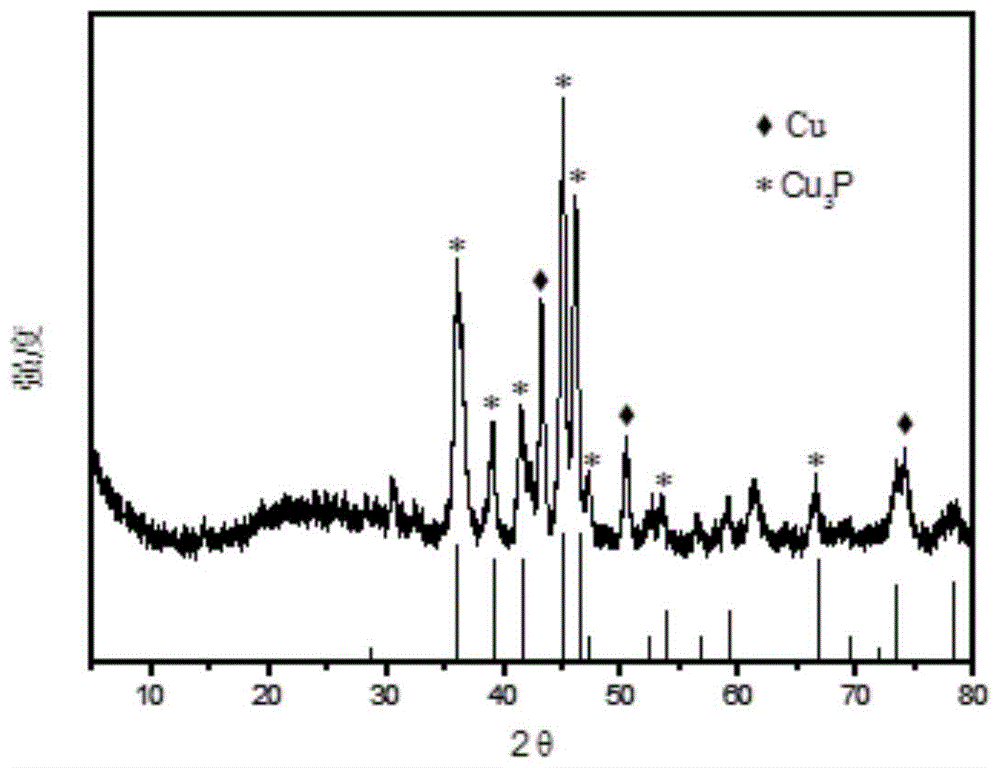

[0034] figure 1 It is the XRD curve figure of the copper phosphide of the present embodiment, as can be seen from this figure, the main component of the synthetic...

Embodiment 2

[0036] S1: red phosphorus powder obtained by ball milling red phosphorus with a purity of 99% for 12 hours, wherein the red phosphorus was purchased from Sinopharm. The copper mesh is purchased from Sinopharm Group. The surface of the copper mesh is treated with hydrochloric acid, and the oxide on the surface of the copper mesh is removed and cleaned by pickling. The copper mesh and red phosphorus powder are sealed in a stainless steel tank filled with inert gas. Wherein, the red phosphorus mass is 0.3 to the copper mesh mass, and the volume of the stainless steel tank is 50ml.

[0037] S2: The stainless steel tank sealed with red phosphorus and copper mesh in step S1 is sintered in a muffle furnace, the sintering temperature is 350° C., and the sintering time is 6 hours.

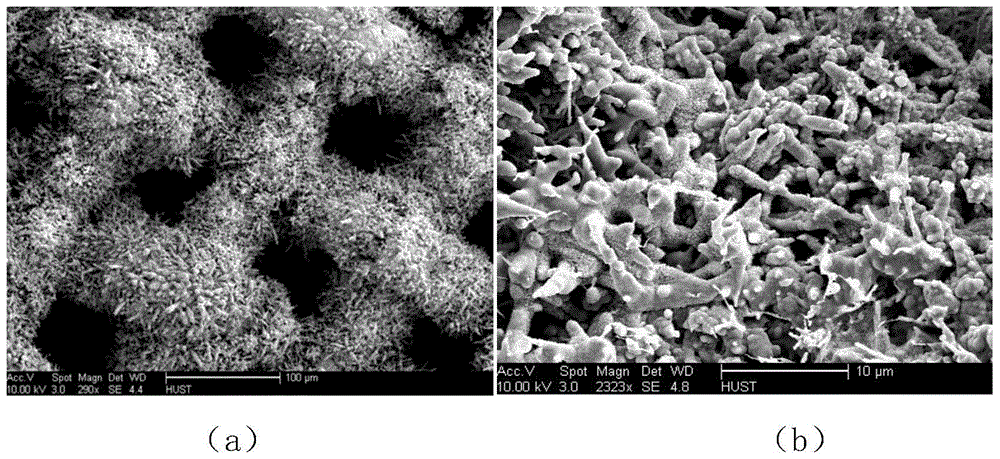

[0038] figure 2 (a), (b) are the present embodiment copper phosphide Cu 3 SEM image of P, figure 2 (a) The magnification is 290 times, figure 2 (b) The magnification is 2323 times. It can be seen fr...

Embodiment 3

[0040] S1: red phosphorus powder obtained by ball milling red phosphorus with a purity of 98.5% for 24 hours, wherein the red phosphorus was purchased from Sinopharm. The copper mesh is purchased from Sinopharm Group. The surface of the copper mesh is treated with hydrochloric acid, and the oxide on the surface of the copper mesh is removed and cleaned by pickling. The copper mesh and red phosphorus powder are sealed in a stainless steel tank filled with inert gas. Wherein, the red phosphorus mass is 0.5 to the copper mesh mass, and the volume of the stainless steel tank is 50ml.

[0041] S2: The stainless steel tank sealed with red phosphorus and copper mesh in step S1 is sintered in a muffle furnace, the sintering temperature is 250° C., and the sintering time is 10 h.

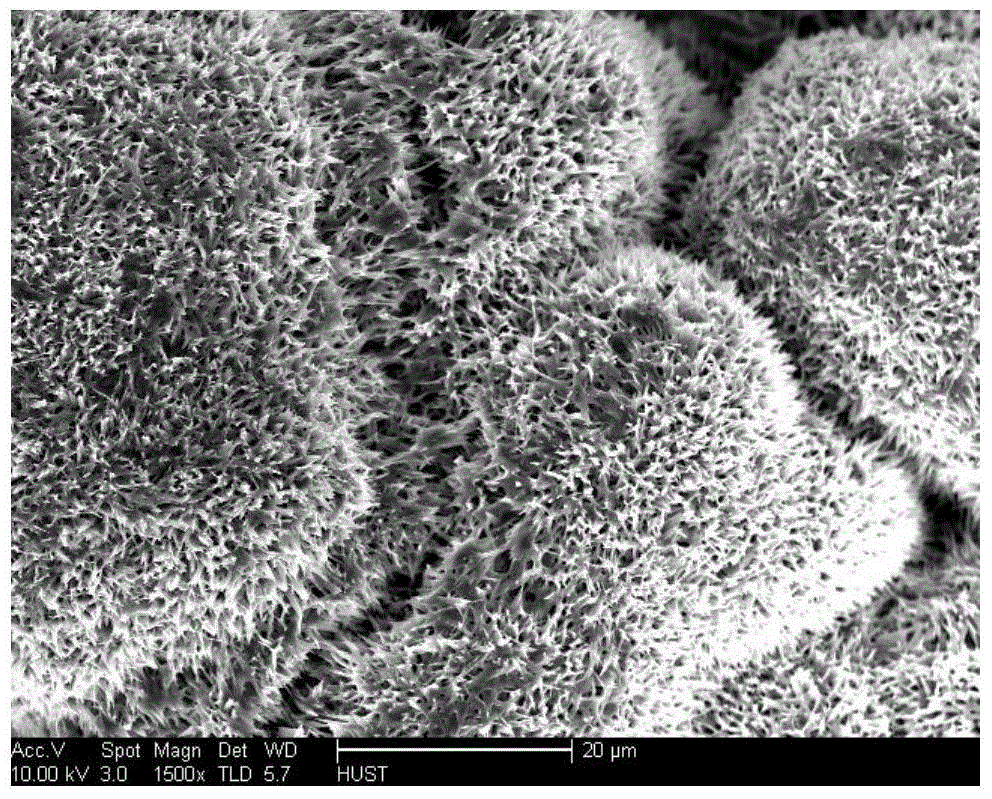

[0042] image 3 It is the scanning electron micrograph of the copper phosphide of this embodiment, and the magnification of this figure is 1500 times. It can be seen from the figure that the synthesized Cu ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com