Microcrystal and bamboo charcoal composite pottery material and preparation method thereof

A microcrystalline bamboo charcoal and pottery technology, applied in the production of ceramic materials, ceramic products, clay products, etc., can solve the problems of high consumption, difficulty in obtaining high-quality pottery, uneven particle size distribution, etc., and achieve high normal far infrared rays. Low emissivity, low firing shrinkage, and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of pottery pellets

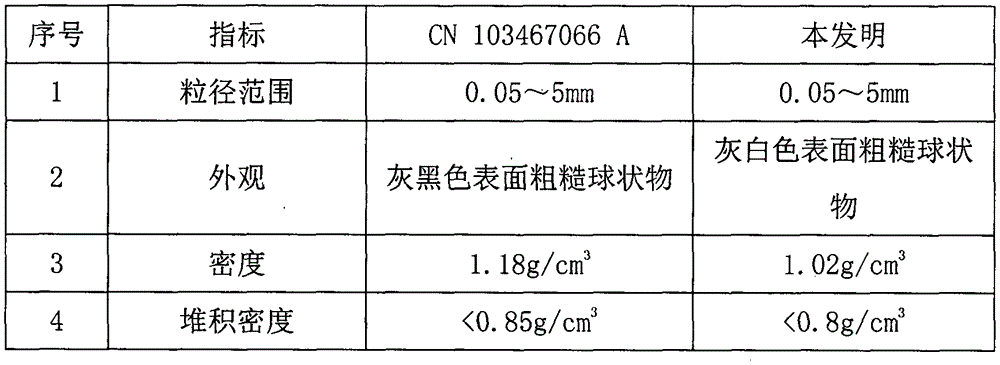

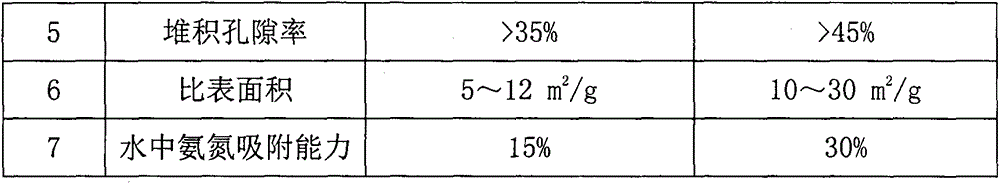

[0033] The average particle size of the bamboo charcoal powder, porous non-metallic mineral powder and clay is 1-10 μm. The porous non-metallic mineral adopts zeolite, and the clay adopts kaolin. The ingredients are mixed according to the ratio of 40% bamboo charcoal, 30% porous minerals, 25% clay and 5% binder. Add water and starch to the granulator to form spherical granules with a particle size of 0.5mm to 5mm, then air-dry the granules naturally for 24 hours, and then dry them in a drying oven at a temperature of 90°C for 4 hours, anaerobic sintering, and sintering temperature Keep at 1250°C for 30 minutes, and cool naturally to obtain pottery pellet products. The performance indicators of the pottery pellets are shown in Table 1.

Embodiment 2

[0035] Preparation of honeycomb pottery

[0036] The average particle size of the bamboo charcoal powder, porous non-metallic mineral powder and clay is 1-10 μm. The porous non-metallic mineral adopts zeolite, and the clay adopts attapulgite. Mix ingredients according to the ratio of 35% bamboo charcoal, 45% porous minerals, 18% clay and 2% binder. The process of preparing microcrystalline bamboo charcoal composite honeycomb pottery is as follows: add water, dextrin smelt, and stale, put the mud into the molding mold and extrude it, let it dry naturally for 24 hours, then put it in a constant temperature drying box, and adjust the temperature to 90°C Dry for more than 4 hours; then put it into a sintering furnace for anaerobic sintering at a sintering temperature of 1200° C., keep for 30 minutes, and naturally cool to obtain a honeycomb ceramic product. The performance index of honeycomb pottery is shown in Table 2.

Embodiment 3

[0038] Preparation of pottery slabs

[0039] The average particle size of the bamboo charcoal powder is 20-40 μm, and the average particle size of the porous non-metallic mineral powder and clay is 40-70 μm. The porous non-metallic mineral adopts volcanic slag, and the clay adopts bentonite. The ingredients are mixed according to the ratio of 25% bamboo charcoal, 45% porous minerals, 28% clay and 2% binder. Add an appropriate amount of water and gum arabic to make granules with a particle size of 0.5-2 mm. Then fill the granulated material into the mold, press 120MPa pressure to form decorative ceramic plates with different appearances, put them into a drying oven at 90°C to dry, then engrave, and finally carry out anaerobic sintering. The sintering temperature was 1300° C. and kept for 45 minutes. Natural cooling to obtain flat pottery products. The performance indicators of the pottery slabs are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com