Method for extracting purified phytosterol from corn stigma

A technology of phytosterols and corn silk, which is applied in the field of extraction and purification of natural phytosterols, can solve the problems of uneconomical economic benefits, complex extraction process, and low product recovery rate, and achieve simple extraction equipment, short process flow, and high product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

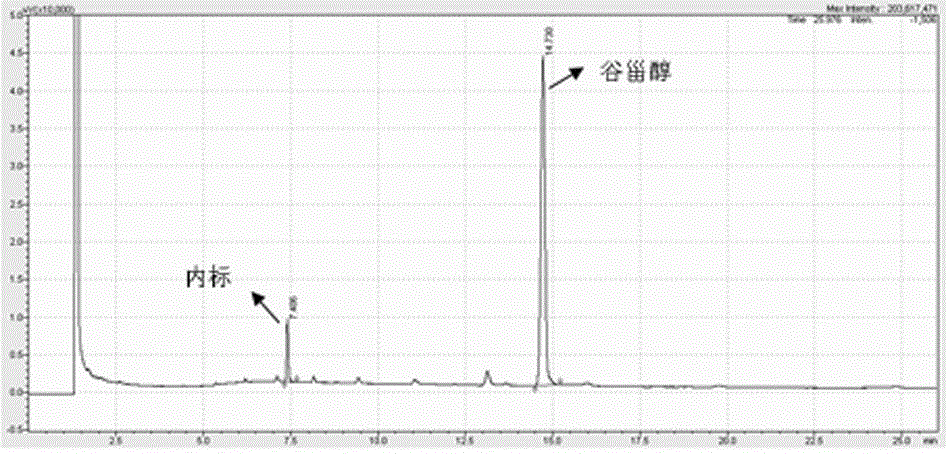

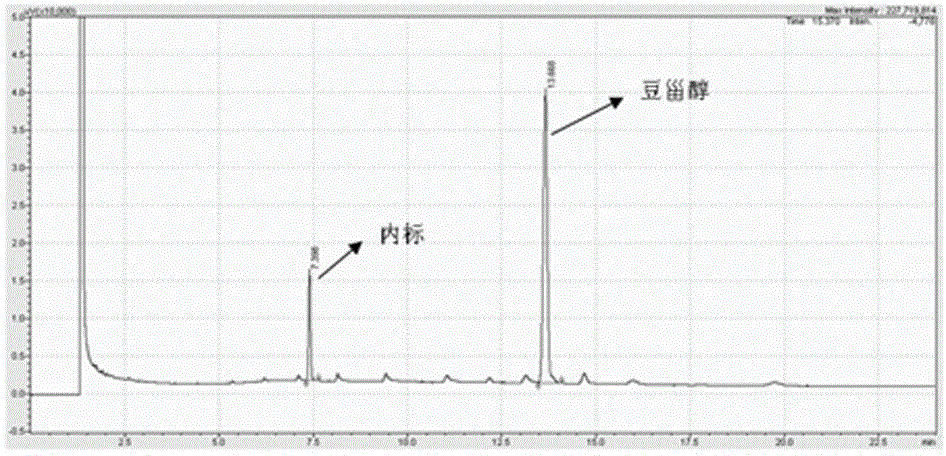

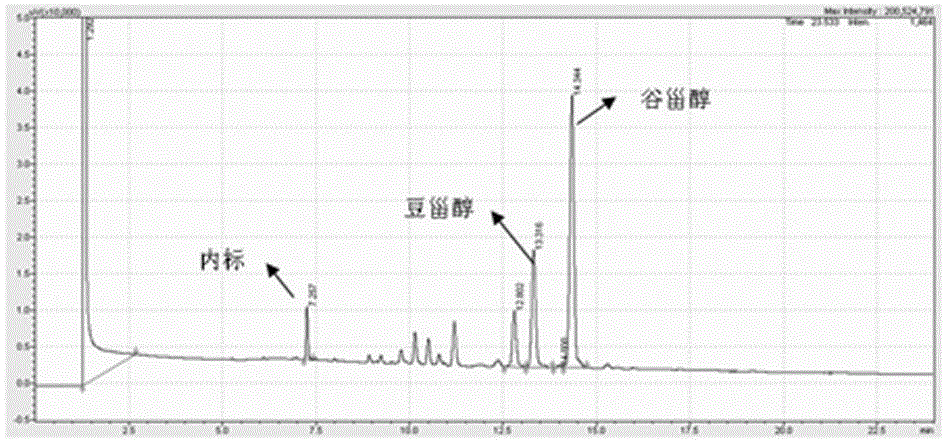

Image

Examples

Embodiment 1

[0024] A method for extracting and purifying phytosterols from corn silk, which comprises the following steps:

[0025] 1) Grind the removed corn silk with a grinder, pass through a 60-mesh sieve, and then dry it in an oven (80°C). Take 50g of crushed and dried corn silk and saponify with 100ml of saponification solution at 85°C for 3h, then add 250ml of absolute ethanol for ultrasonic extraction for 0.5h, centrifuge for 30min after ultrasonic extraction, take the supernatant, and rotary evaporate to obtain the crude extract. Described saponification liquid is the potassium hydroxide ethanol solution of concentration 3mol / L, is about to dissolve an appropriate amount of potassium hydroxide in 80V% ethanol to obtain saponification liquid;

[0026] 2) The crude extract was extracted with a mixed solution of water and ether at a volume ratio of 1:5, and the organic phase was rotary evaporated to obtain a concentrated extract, which was then recrystallized with ethyl acetate to ob...

Embodiment 2

[0028] A method for extracting and purifying phytosterols from corn silk, which comprises the following steps:

[0029] 1) Grind the removed corn silk with a grinder, pass through a 60-mesh sieve, and then dry it in an oven (80°C). Take 50g of crushed and dried corn silk and saponify with 300ml of saponification solution at 75°C for 4h, then add 300ml of absolute ethanol for ultrasonic extraction for 1h, centrifuge for 30min after ultrasonic extraction, take the supernatant, and rotary evaporate to obtain the crude extract. Described saponification liquid is the potassium hydroxide ethanol solution of concentration 4mol / L, is about to dissolve appropriate amount of potassium hydroxide in 90V% ethanol to obtain saponification liquid;

[0030] 2) The crude extract was extracted with a mixed solution of water and ether at a volume ratio of 1:6, and the organic phase was rotary evaporated to obtain a concentrated extract, which was then recrystallized from ethyl acetate to obtain ...

Embodiment 3

[0032] A method for extracting and purifying phytosterols from corn silk, which comprises the following steps:

[0033] 1) Grind the removed corn silk with a grinder, pass through a 60-mesh sieve, and then dry it in an oven (80°C). Take 50g of crushed and dried corn silk and saponify with 200ml of saponification solution at 90°C for 2h, then add 400ml of absolute ethanol for ultrasonic extraction for 0.5h, centrifuge for 30min after ultrasonic extraction, take the supernatant, and rotary evaporate to obtain the crude extract. Described saponification liquid is the potassium hydroxide ethanol solution of concentration 3mol / L, is about to be dissolved in an appropriate amount of potassium hydroxide in 85V% ethanol to obtain saponification liquid;

[0034] 2) The crude extract was extracted with a mixed solution of water and ether at a volume ratio of 1:8, and the organic phase was rotary evaporated to obtain a concentrated extract, which was then recrystallized with ethyl acetat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com