Up-conversion luminescent material as well as preparation method and application thereof

A luminescent material and chemical technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of low luminous efficiency and large size, and achieve the effects of high luminous efficiency, small size and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of the up-conversion luminescent material: a solvothermal method using octadecene as a solvent and oleic acid as a complexing agent. The method has a low reaction temperature, is easy to operate, and has no pollution to the environment, and specifically includes the following steps :

[0042] 1) According to the stoichiometric ratio of each element in the general chemical formula (1), weigh the 3+ compounds containing R 3+ Compounds containing Yb 3+ compounds and containing M 3+ The compound is added in the three-necked flask;

[0043] 2) After adding oleic acid and octadecene into the three-necked flask at a volume ratio of 2:5, under nitrogen or inert gas conditions, heat to 140-180°C for 30-60 minutes, then cool to 50°C, Form solution A;

[0044] 3) According to F in the general chemical formula (1) - and Na + The stoichiometric ratio of NH 4 F and excess NaOH are dissolved in methanol to obtain solutio...

Embodiment 1

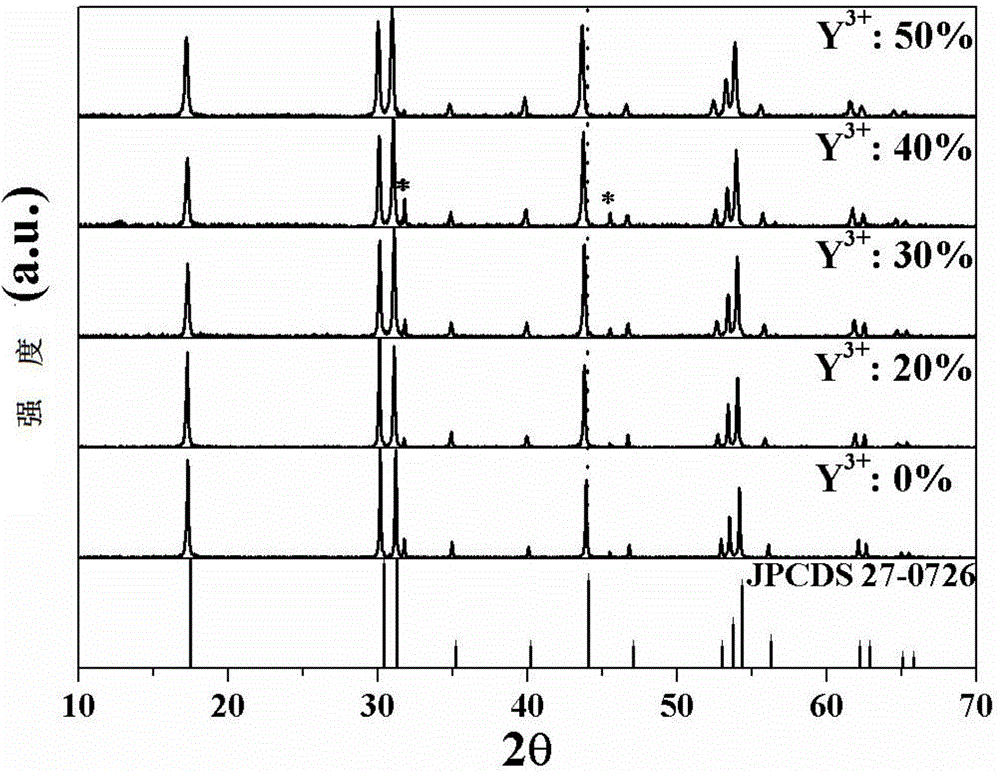

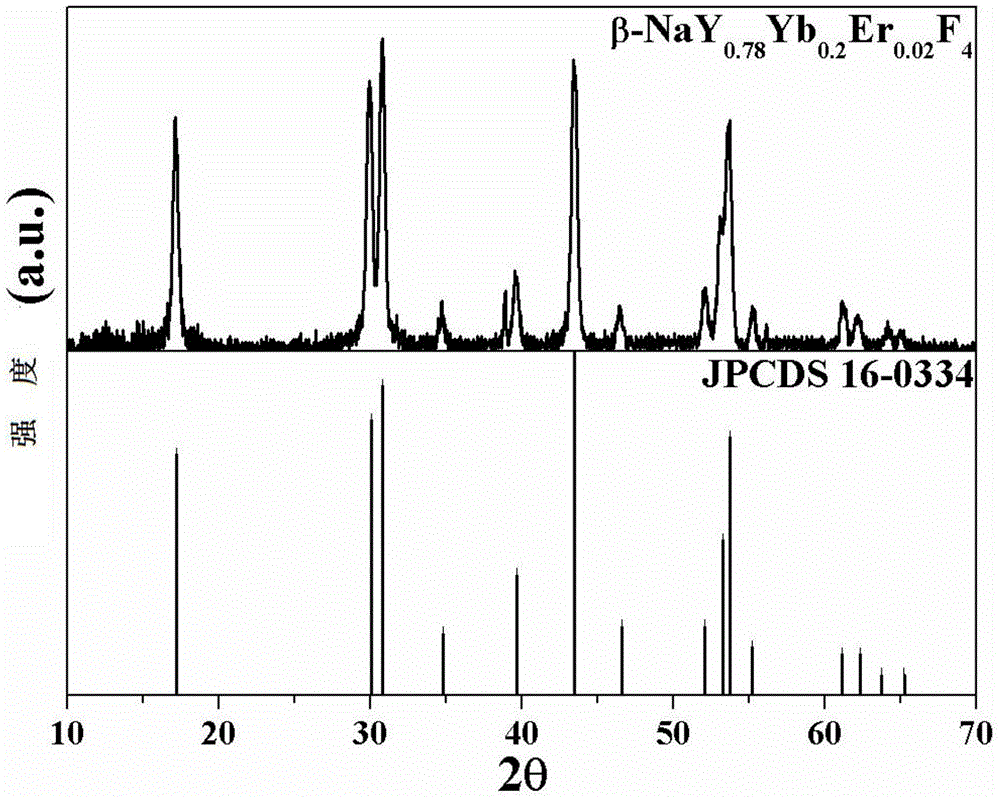

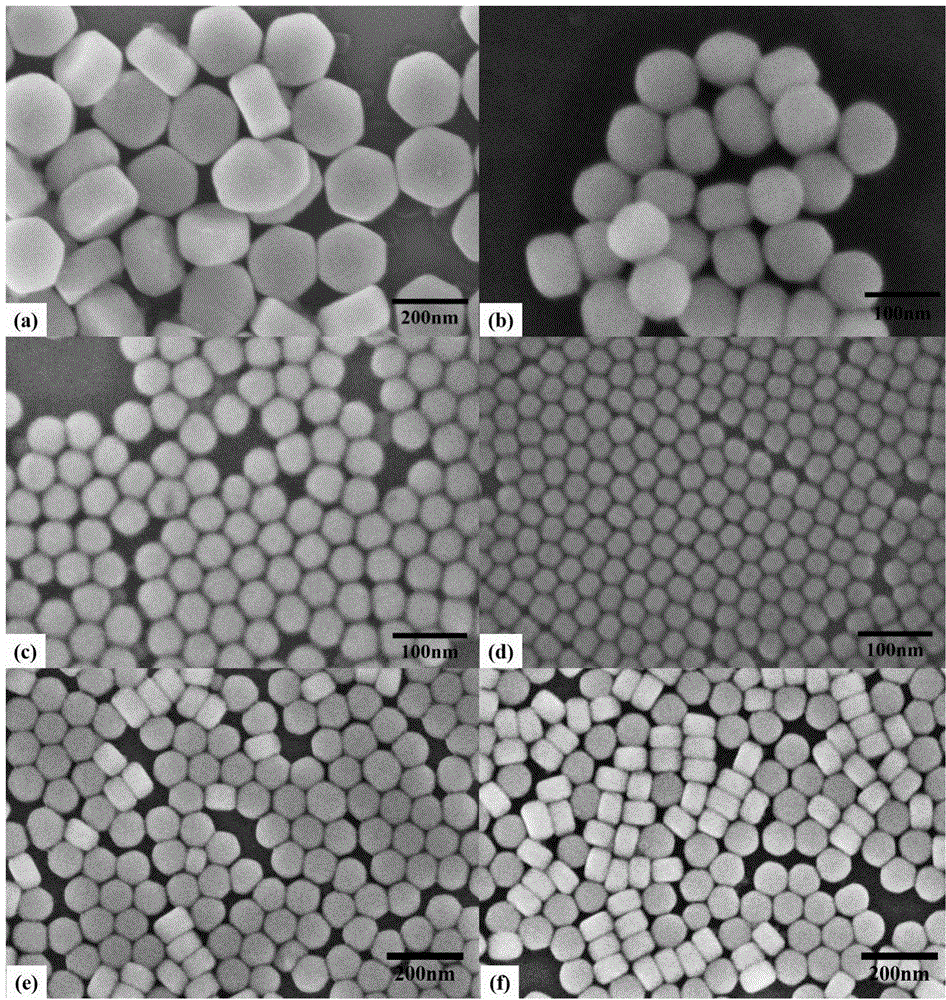

[0054] β-NaLu 0.78 Yb 0.2 Er 0.02 f 4 preparation of

[0055] According to the chemical formula NaLu 0.78 Yb 0.2 Er 0.02 f 4 The stoichiometric ratio of each element in, respectively weighed 0.2195g LuCl 3 , 0.0559g YbCl 3 and 0.0055g ErCl 3 , was added to a 100ml three-necked flask; then 6ml of oleic acid and 15ml of octadecene were added to the three-necked flask, and under the protection of nitrogen, the solution was heated to 140°C for 30 minutes, then cooled to 50°C to form solution A; 0.148g NH 4 F. Dissolve 0.1g NaOH into 10ml of methanol solution and mix well, then slowly inject into solution A, keep the temperature at 50°C for 30 minutes to evaporate the methanol; continue to heat the solution to 300°C for 1.5 hours, then cool to room temperature, Form nanocrystals; precipitate nanocrystals with excess absolute ethanol, centrifuge 3 times at a speed of 5000 rpm, and obtain a white paste that is β-NaLu 0.78 Yb 0.2 Er 0.02 f 4 Up-converting luminescent ma...

Embodiment 2

[0061] β-NaLu 0.58 Y 0.2 Yb 0.2 Er 0.02 f 4 preparation of

[0062] According to the chemical formula NaLu 0.58 Y 0.2 Yb 0.2 Er 0.02 f 4 The stoichiometric ratio of each element in , respectively weighed 0.1633gLuCl 3 , 0.0391g YCl 3 , 0.0559g YbCl 3 and 0.0055g ErCl 3 , was added to a 100ml three-necked flask; then 6ml of oleic acid and 15ml of octadecene were added to the three-necked flask, and under the protection of nitrogen, the solution was heated to 140°C for 30 minutes at a constant temperature, and then cooled to 50°C to form solution A; 0.148g NH 4 F. Dissolve 0.1g NaOH in 10ml of methanol solution and mix well, then slowly inject into solution A, and keep the temperature at 50°C for 30 minutes to evaporate the methanol; continue to heat the solution to 300°C for 1.5 hours, then cool to room temperature , to form nanocrystals; precipitate nanocrystals with excess absolute ethanol, and centrifuge 3 times at a speed of 5000 rpm to obtain a white paste, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com