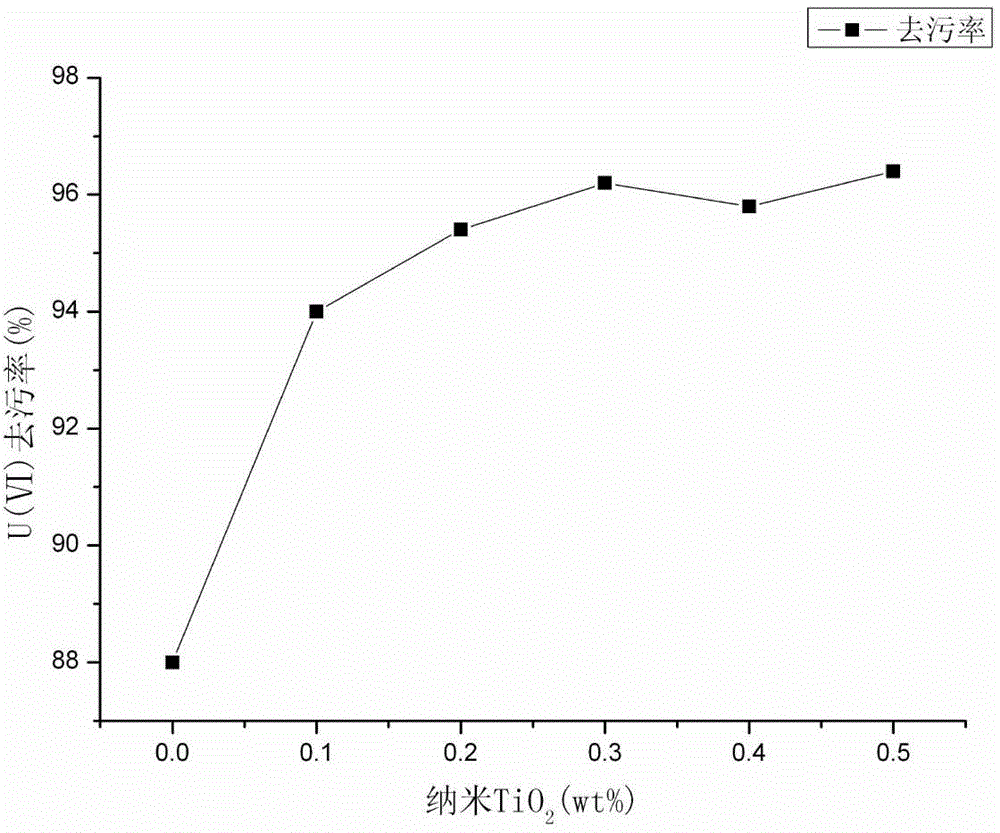

Nano inorganic material and alkyl glycoside compounded radionuclide decontaminant as well as use method thereof

A nano-inorganic material, radionuclide technology, applied in the directions of radioactive purification, detergent compounding agent, organic washing composition, etc. problems, to achieve good ecological safety and compatibility, rapid and thorough degradation, and easy handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

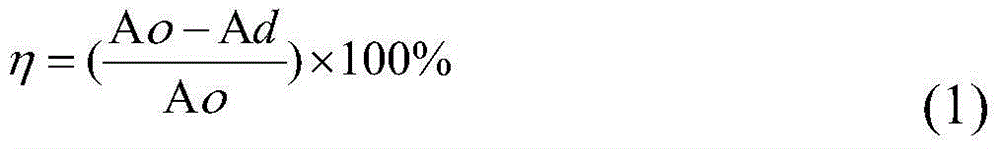

Method used

Image

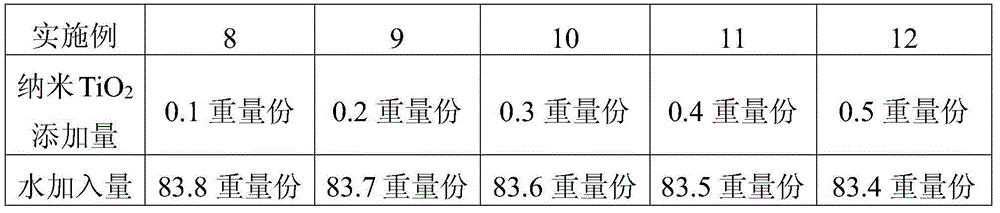

Examples

Embodiment 1

[0049] Take 0.5 parts by weight of alkyl glycosides with 10 carbon atoms and 0.5 parts by weight of nano-TiO 2 , 5 parts by weight sodium citrate, 1 part by weight sodium carbonate, 5 parts by weight urea, 0.2 parts by weight sodium carboxymethyl cellulose, 0.2 parts by weight sodium dodecylbenzene sulfonate, 0.1 parts by weight sodium polycarboxylate, 1 Parts by weight of NaCl, 0.1 parts by weight of phenol, 0.5 parts by weight of purified konjac glucomannan, and 85.9 parts by weight of water are mixed uniformly to obtain a foam detergent solution.

[0050] Stir the resulting solution at 3000 r / min to obtain a stable foam, spray the foam on the surface of the contaminated paint, let it stand for 5 minutes, and blow the foam into the waste liquid bucket with a blast blowing device for subsequent treatment.

[0051] Put the foam in the waste liquid bucket under the light condition for 2h, the foam disappears, the waste liquid is stirred at 3000r / min without foam generation, and the w...

Embodiment 2

[0053] Take 1 part by weight of alkyl glycoside with 10 carbon atoms and 0.5 part by weight of nano Fe 2 O 3 , 5 parts by weight sodium citrate, 1 part by weight sodium carbonate, 5 parts by weight urea, 0.3 parts by weight sodium carboxymethyl cellulose, 0.2 parts by weight sodium dodecylbenzene sulfonate, 0.4 parts by weight sodium polycarboxylate, 1 Parts by weight of NaCl, 0.1 parts by weight of phenol, 0.5 parts by weight of purified konjac glucomannan, and 85 parts by weight of water are mixed uniformly to obtain a foam detergent solution.

[0054] Stir the resulting solution at 3000 r / min to obtain a stable foam, spray the foam on the surface of the contaminated paint, let it stand for 8 minutes, and blow the foam into the waste liquid bucket with a blast blowing device for subsequent treatment.

[0055] Place the foam in the waste liquid bucket under light conditions for 3 hours, the foam disappears, the waste liquid is stirred at 3000r / min without foam generation, and the w...

Embodiment 3

[0057] Take 1.5 parts by weight of alkyl glycosides with 10 alkyl carbon atoms, 1 part by weight of nano-ZnO, 5 parts by weight of disodium edetate, 3 parts by weight of sodium carbonate, 5 parts by weight of urea, 0.4 parts by weight of carboxymethyl Sodium cellulose, 0.2 parts by weight of sodium dodecylbenzene sulfonate, 0.1 parts by weight of sodium polycarboxylate, 1 part by weight of NH 4 Cl, 0.1 parts by weight of paraben, 0.5 parts by weight of purified konjac glucomannan, and 84.2 parts by weight of water are mixed uniformly to obtain a foam detergent solution.

[0058] Stir the resulting solution at 3000 r / min to obtain a stable foam, spray the foam on the surface of the contaminated paint, let it stand for 5 minutes, and blow the foam into the waste liquid bucket with a blast blowing device for subsequent treatment.

[0059] Put the foam in the waste liquid bucket under the light condition for 5 hours, the foam disappears, the waste liquid is stirred at 3000r / min without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com