Method for preparing antistatic anti-felting wool fabric with good dyeing property

A dyeing performance and anti-felting technology, which is applied in animal fibers, textiles, papermaking, fiber treatment, etc., can solve the problems of difficulty in ensuring the uniformity of the chlorination process, rough hand feeling, easy yellowing of wool, etc., and achieve excellent drapability and warmth retention, reduction of directional friction effect, smoothing effect of wool surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

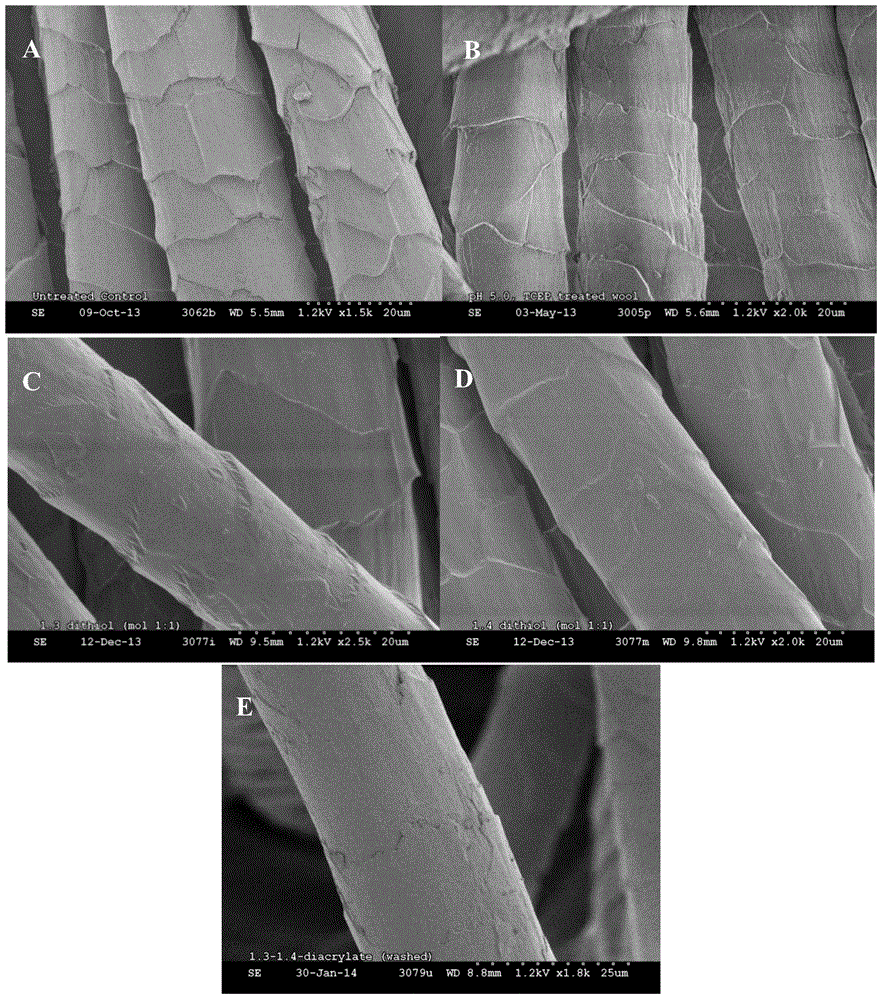

Embodiment 1

[0031] Merino plain weave wool worsted fabrics with warp and weft densities of 23 counts / cm and 20 counts / cm, and an areal density of 190 g / m2 are used to produce worsted wool fabrics with strong unidirectional moisture conductivity. The steps are:

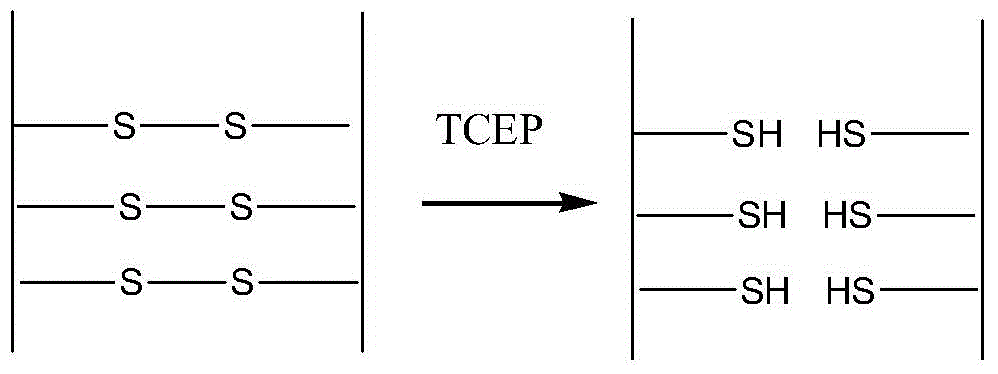

[0032] (1) Pre-treatment:

[0033] a. Weigh 4g worsted fabric;

[0034] b. Take 1.147g of TCEP solid powder, place it in a 250mL beaker, add 200mL water / ethanol (volume ratio 1:1) solution, stir evenly, get 5.733g / L TCEP solution, use pH 10 Na 2 CO 3 / NaHCO 3 Adjust the pH of the buffer solution to 5;

[0035] c. Dip the worsted fabric into the TCEP solution, and seal the film on the mouth of the beaker;

[0036] d. Place the beaker in a constant-temperature magnetic stirring water bath and shake for 4 hours at 25°C;

[0037] e. Take out the worsted fabric, wash thoroughly in distilled water, and dry at 60°C.

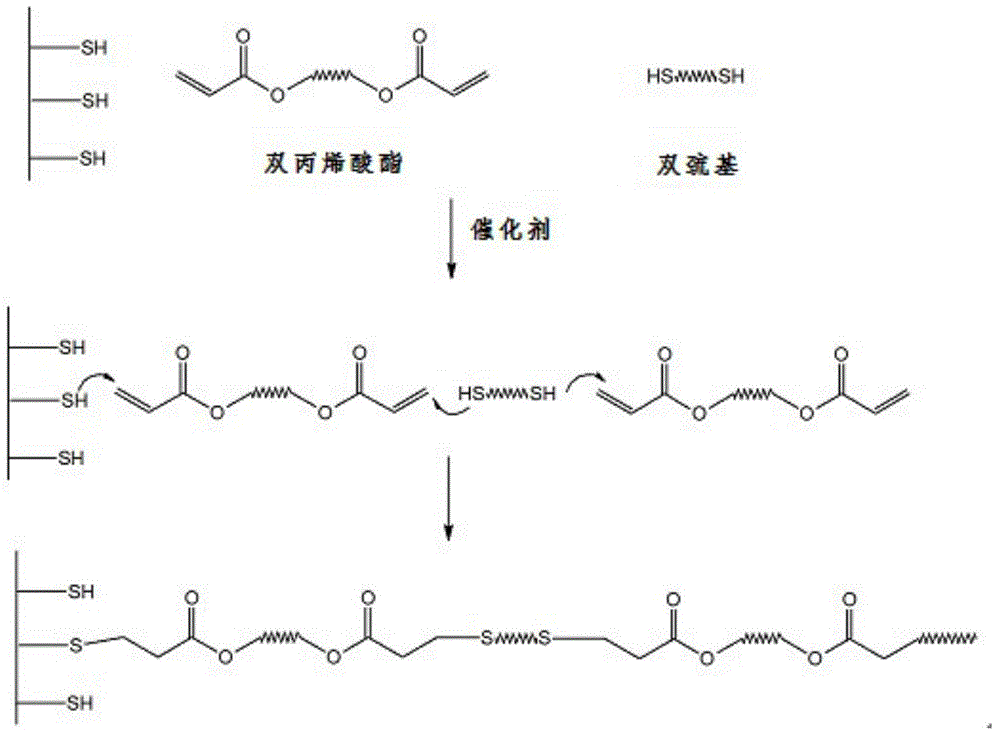

[0038] (2) Finishing:

[0039] f. Take 10 mL of 1,4-butanediol acrylate solution (a 90% mass concentration aqueous solution) and diss...

Embodiment 2

[0043] Merino plain weave wool worsted fabrics with warp and weft densities of 23 counts / cm and 20 counts / cm, and an areal density of 190 g / m2 are used to produce worsted wool fabrics with strong unidirectional moisture conductivity. The steps are:

[0044] (1) Pre-treatment:

[0045] a. Take 4g worsted fabric;

[0046] b. Take 1.1g of TCEP solid powder, place it in a 250mL beaker, add 200mL of water / ethanol (volume ratio 1:1) solution, stir evenly to obtain 5.7g / L TCEP solution, use pH 10 Na 2 CO 3 / NaHCO 3 Adjust the pH of the buffer solution to 5;

[0047] c. Dip the worsted fabric into the TCEP solution, and seal the film on the mouth of the beaker;

[0048] d. Place the beaker in a constant-temperature magnetic stirring water bath and shake for 4 hours at 25°C;

[0049] e. Take out the worsted fabric, wash thoroughly in distilled water, and dry at 60°C.

[0050] (2) Finishing:

[0051] f. Take 10mL of 1,4-butanediol acrylate solution (90% mass concentration aqueous solution) dissolve...

Embodiment 3

[0055] Merino plain weave wool worsted fabrics with warp and weft densities of 23 counts / cm and 20 counts / cm, and an areal density of 190 g / m2 are used to produce worsted wool fabrics with strong unidirectional moisture conductivity. The steps are:

[0056] (1) Pre-treatment:

[0057] a. Take 4g worsted fabric;

[0058] b. Take 1.1g of TCEP solid powder, place it in a 250mL beaker, add 200mL of water / ethanol (volume ratio 1:1) solution, stir evenly to obtain 5.7g / L TCEP solution, use pH 10 Na 2 CO 3 / NaHCO 3 Adjust the pH of the buffer solution to 5;

[0059] c. Dip the worsted fabric into the TCEP solution, and seal the film on the mouth of the beaker;

[0060] d. Place the beaker in a constant-temperature magnetic stirring water bath and shake for 4 hours at 25°C;

[0061] e. Take out the worsted fabric, wash thoroughly in distilled water, and dry at 60°C.

[0062] (2) Finishing:

[0063] f. Take 10 mL of 1,4-butanediol acrylate solution (a 90% mass concentration aqueous solution) and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com