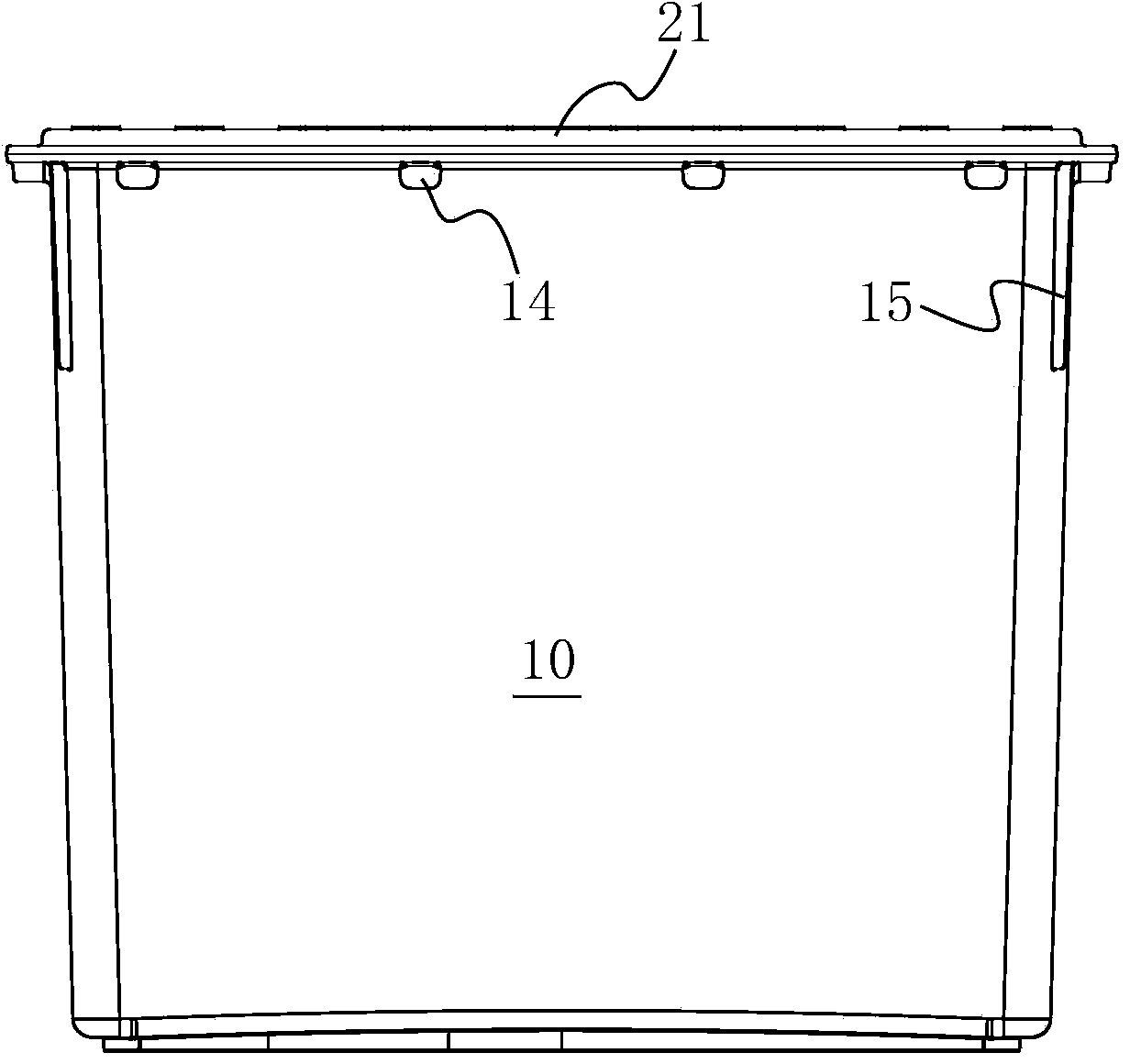

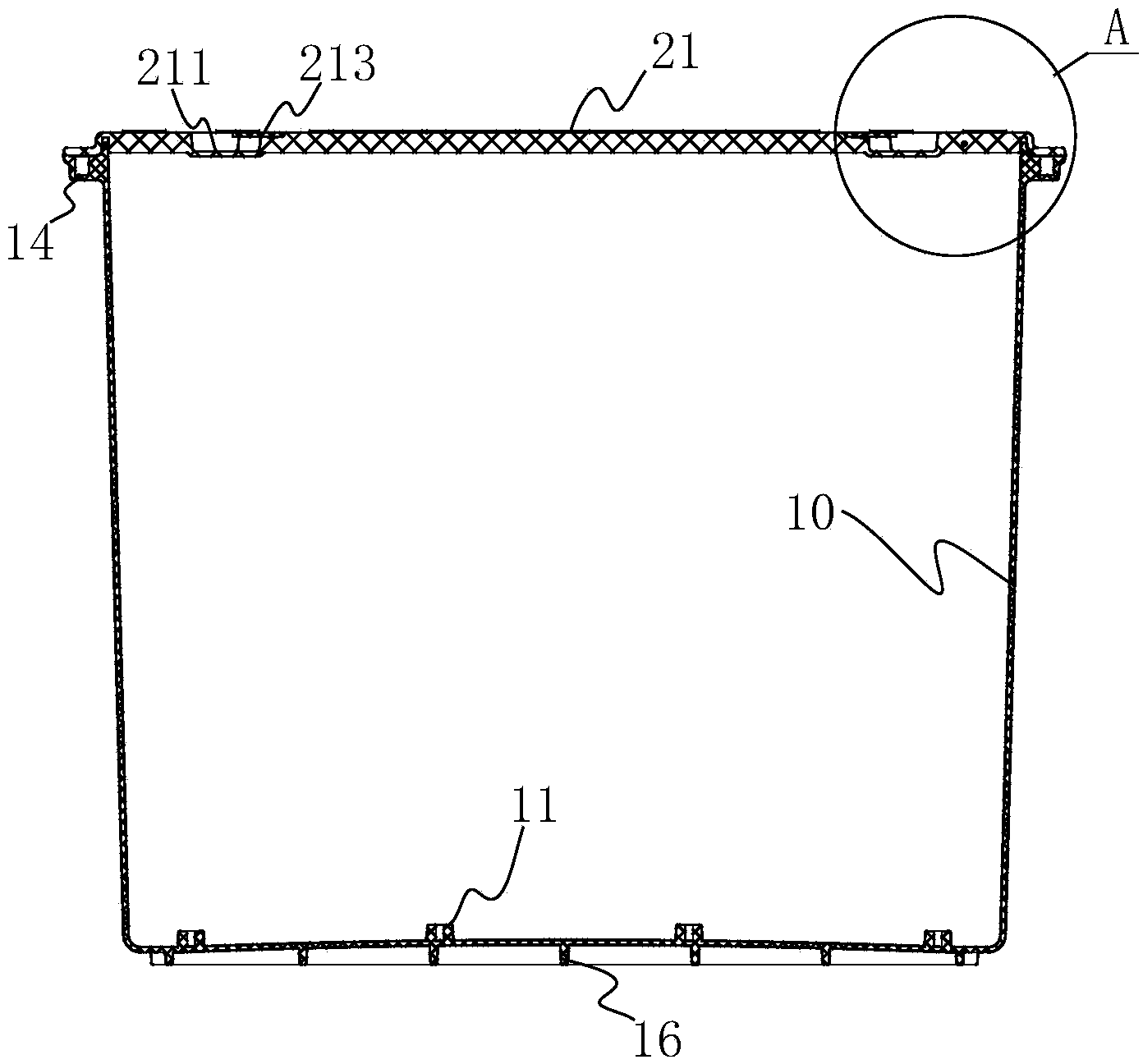

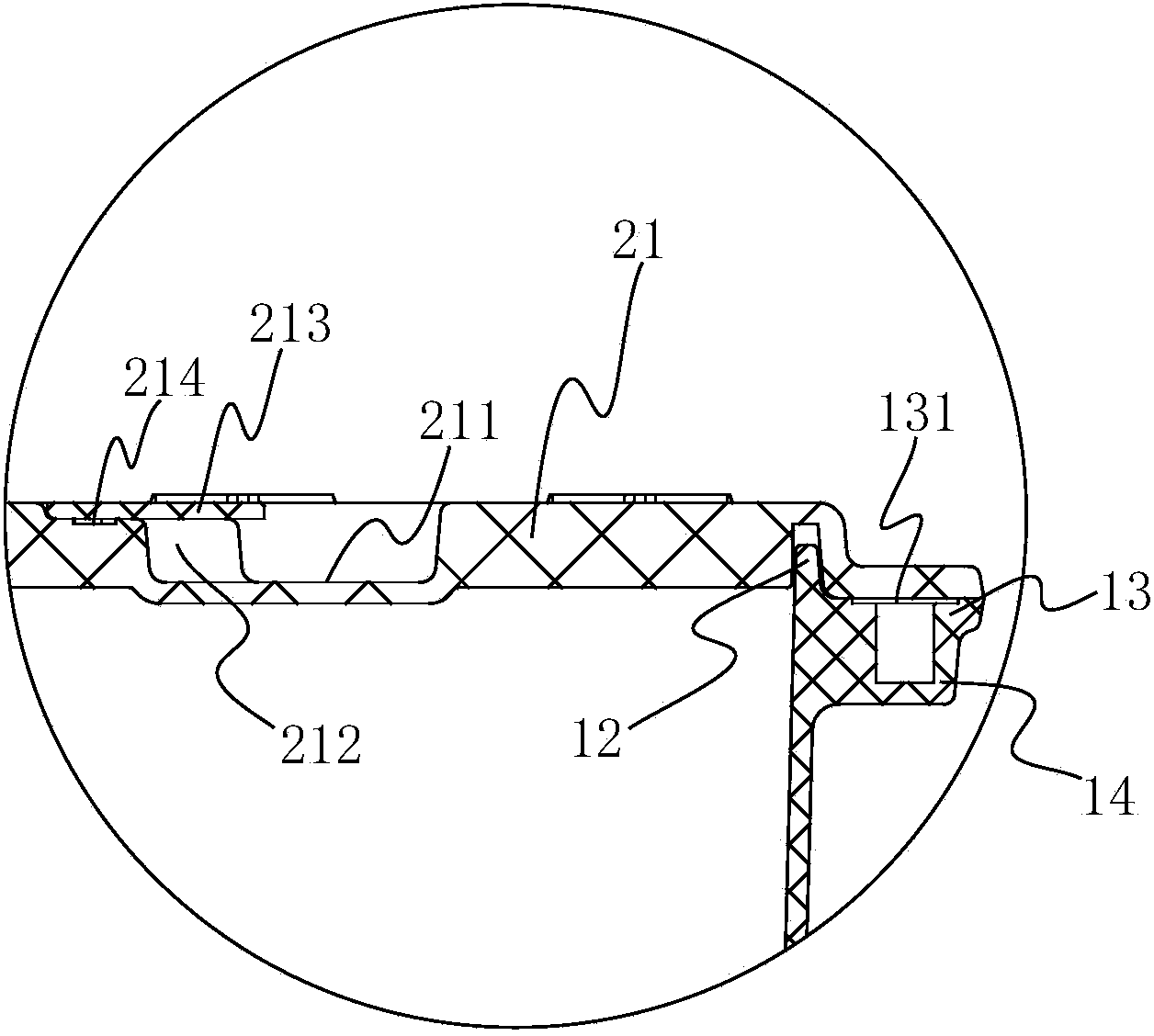

High-strength plastic valve well

A high-strength plastic and valve well technology, applied in the field of valve wells, can solve problems such as plastic valve well deformation, plastic valve well application technical obstacles, damage, etc., achieve low cost, avoid transportation and installation damage, and prevent water leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Weight composition of plastic:

[0068] 90 parts of o-phthalic resin,

[0069] 35 parts polystyrene,

[0070] 180 parts of calcium carbonate superfine powder,

[0071] 100 parts of glass fiber with a length of 1-50mm,

[0072] 3 parts of tert-butyl peroxy-2-ethylhexanoate,

[0073] BYK-W966: 2 copies,

[0074] Magnesium stearate 5 parts,

[0075] 2 parts of MgO powder passed through a 400 mesh sieve,

[0076] 3 parts styrene,

[0077] 6 parts reactive polyamide,

Embodiment 2

[0080] Weight composition of plastic:

[0081] 110 parts of m-benzene resin,

[0082] 30 parts polystyrene,

[0083] 160 parts of calcium carbonate superfine powder,

[0084] 110 pieces of glass fiber with a length of 1-50mm,

[0085] 3 parts of tert-butyl peroxy-2-ethylhexanoate,

[0086] BYK-W9010: 1 part,

[0087] Zinc stearate and magnesium stearate are mixed 5 parts at a ratio of 1:1,

[0088] 2 parts of MgO powder passed through a 400 mesh sieve,

[0089] 3 parts styrene,

[0090] 5 parts reactive polyamide,

[0091] Aluminum hydroxide superfine powder 15 parts.

Embodiment 3

[0093] Weight composition of plastic:

[0094] Vinyl resin 100 parts,

[0095] 30 parts polystyrene,

[0096] 150 parts of calcium carbonate superfine powder,

[0097] 100 parts of glass fiber with a length of 1-50mm,

[0098] 3 parts of tert-butyl peroxy-2-ethylhexanoate,

[0099] BYK-W9010: 1 part,

[0100] Zinc stearate 5 parts,

[0101] 1 part of MgO powder passed through a 400 mesh sieve,

[0102] 3 parts styrene,

[0103] 5 parts reactive polyamide,

[0104] Aluminum hydroxide superfine powder 15 parts.

[0105] The processing methods of the three embodiments are the same, and they are also relatively conventional molding processes:

[0106] The glass fiber is treated with a silane coupling agent; the raw materials other than the glass fiber are stirred and mixed with a high-speed disperser, and then impregnated with the short glass fiber; the sheet is made into a sheet covered with PE film on both sides.

[0107] Thicken the sheet at 40-45°C for 48 hours to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com