Cathode material for sodium-ion battery and preparation method of cathode material

A sodium-ion battery and positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as electrode material structure collapse, and achieve the effects of improving capacity and cycle life, improving stretchability, and increasing voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

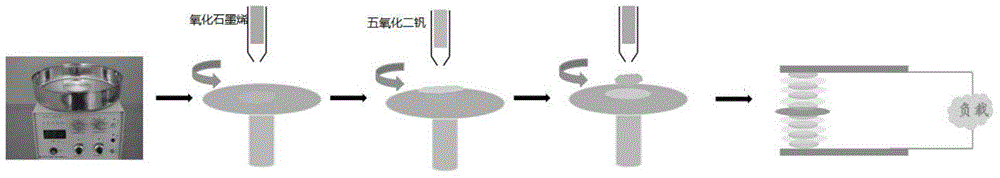

[0028] A kind of positive electrode material of sodium ion battery, its preparation method is as follows:

[0029] 1) prepare the colloidal solution of vanadium pentoxide of saturated concentration with vanadium pentoxide powder and hydrogen peroxide, and prepare the graphene oxide aqueous solution that concentration is 4mg / mL with graphite powder by Hummers method;

[0030] 2) Evenly coat the graphene oxide aqueous solution on the base aluminum sheet, and then dry it on a heating platform at 60°C;

[0031] 3) coating the colloidal solution of vanadium pentoxide evenly on the aluminum sheet loaded with graphene oxide prepared in step 2), and then drying it on a heating platform at 60°C;

[0032] 4) Then, the graphene oxide aqueous solution is evenly coated on the aluminum sheet loaded with graphene oxide and vanadium pentoxide prepared in step 3), and dried on a heating platform at 60°C;

[0033] 5) Repeat step 2) to step 4) twice;

[0034] 6) The coated electrode material i...

Embodiment 2

[0036] A kind of positive electrode material of sodium ion battery, its preparation method is as follows:

[0037] 1) prepare the colloidal solution of vanadium pentoxide of saturated concentration with vanadium pentoxide powder and hydrogen peroxide, and prepare the graphene oxide aqueous solution that concentration is 9mg / mL with graphite powder by Hummers method;

[0038] 2) Spin-coat the graphene oxide aqueous solution on the base aluminum sheet, and then dry it on a heating platform at 60°C;

[0039] 3) spin-coat the colloidal solution of vanadium pentoxide on the aluminum sheet loaded with graphene oxide obtained in step 2), and dry it on a heating platform at 60°C;

[0040] 4) Then, the graphene oxide aqueous solution is spin-coated on the aluminum sheet loaded with graphene oxide and vanadium pentoxide prepared in step 3), and dried on a heating platform at 60°C;

[0041] 5) Repeat step 2) to step 4) twice;

[0042] 6) Vacuum-dry the spin-coated electrode material at...

Embodiment 3

[0044] A kind of positive electrode material of sodium ion battery, its preparation method is as follows:

[0045] 1) prepare the vanadium pentoxide colloidal solution that concentration is 0.1mol / L with vanadium pentoxide powder and hydrogen peroxide, and prepare the graphene oxide aqueous solution that concentration is 6mg / mL with graphite powder by Hummers method;

[0046] 2) Spin-coat the graphene oxide aqueous solution on the base aluminum sheet, and then dry it on a heating platform at 40°C;

[0047] 3) Spin-coat the colloidal solution of vanadium pentoxide on the aluminum sheet loaded with graphene oxide obtained in step 2), and dry it on a heating platform at 40°C;

[0048] 4) Then spin-coat the graphene oxide aqueous solution on the aluminum sheet loaded with graphene oxide and vanadium pentoxide prepared in step 3), and dry it on a heating platform at 40°C;

[0049] 5) Dry the spin-coated electrode material in vacuum at a temperature of 120° C. for 12 hours, and fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com