Preparation method of Ru-Ni bimetallic based ordered mesoporous carbon catalyst

A bimetallic, mesoporous carbon technology, applied in the field of composite materials, can solve the problems of complicated steps, uneven distribution of catalyst active components, poor stability, etc., and achieve the effects of economical steps, low cost and simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

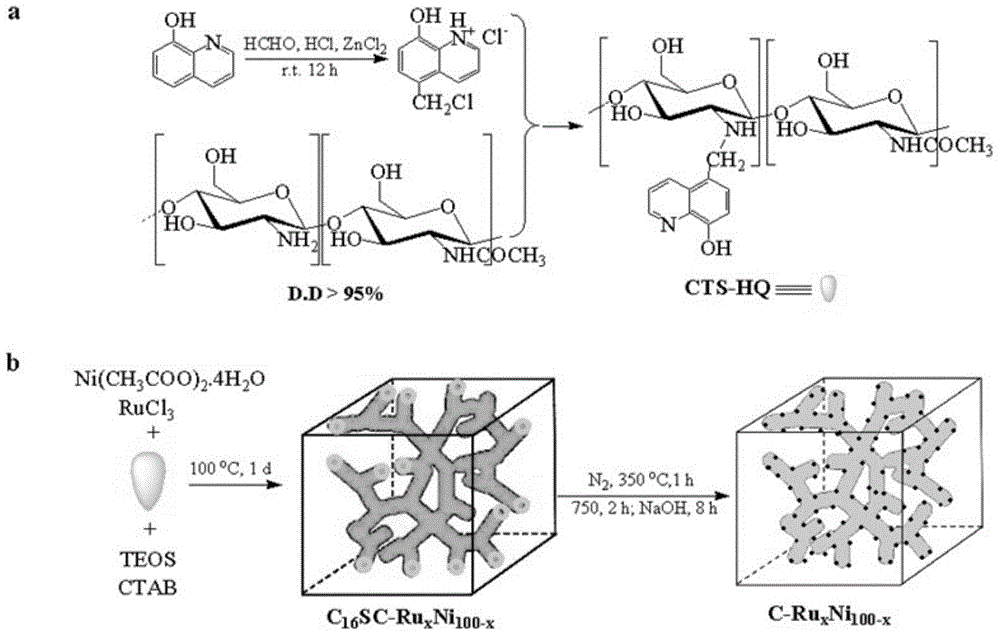

[0034] First, chloromethylation was carried out on 8-hydroxyquinoline, 5.84g 8-hydroxyquinoline, 6.4mL HCHO aqueous solution (37wt%) were mixed with 50mL concentrated hydrochloric acid, and 0.6g ZnCl was added 2as a catalyst. Stir at room temperature for 24 hours, filter and wash to obtain 5-chloromethyl-8-hydroxyquinoline hydrochloride. Dissolve 0.9g of CTS in 50ml of 20wt% acetic acid, then add 4.6g of 5-chloromethyl-8-hydroxyquinoline hydrochloride and 60ml of 36wt% triethylamine aqueous solution, reflux at 75°C for 36h, filter and wash to obtain light yellow The sample is denoted as CTS-HQ. Using CTAB as structure directing agent, TEOS as silicon source, CTS-HQ as carbon source, Ni(CH 3 COO) 2 4H 2 O and RuCl 3 Synthesis of mesoscopic complex C for metal precursors 16 SC-Ru x Ni 100-x . The specific method is: weigh 0.5g CTAB and 18.5ml H 2 O stirred to dissolve, add 7.0ml EtOH and 6.85ml NH 3 ·H 2 O (25.0wt%), then add 2.6ml TEOS, add 1.9g CTS-HQ with a total ...

Embodiment 2

[0036] Firstly, chloromethylation was carried out on 8-hydroxyquinoline. Mix 1g of 8-hydroxyquinoline, 1mL HCHO aqueous solution (37wt%) and 10mL concentrated hydrochloric acid, and add 0.1g ZnCl 2 as a catalyst. Stir at room temperature for 72h, filter and wash to obtain 5-chloromethyl-8-hydroxyquinoline hydrochloride. Dissolve 1g of CTS in 10ml of 20wt% acetic acid, then add 1g of 5-chloromethyl-8-hydroxyquinoline hydrochloride and 10ml of 36wt% triethylamine aqueous solution, reflux at 40°C for 72h, filter and wash to obtain a light yellow sample, Denote it as CTS-HQ. Using CTAB as structure directing agent, TEOS as silicon source, CTS-HQ as carbon source, Ni(CH 3 COO) 2 4H 2 O and RuCl 3 Synthesis of mesoscopic complex C for metal precursors 16 SC-Ru x Ni 100-x . The specific method is: weigh 0.04g CTAB and 1.85ml H 2 O stirred to dissolve, add 0.7ml EtOH and 0.85ml NH 3 ·H 2 O (25.0wt%), then add 0.1ml TEOS, add 0.76g CTS-HQ with a total of 0.12mmol RuCl 3 , ...

Embodiment 3

[0038] First, carry out chloromethylation modification to 8-hydroxyquinoline, mix 15g 8-hydroxyquinoline, 15mL HCHO aqueous solution (37wt%) and 200mL concentrated hydrochloric acid, and add 10g ZnCl 2 as a catalyst. Stir at room temperature for 12 h, filter and wash to obtain 5-chloromethyl-8-hydroxyquinoline hydrochloride. Dissolve 15g of CTS in 250ml of 20wt% acetic acid, then add 15g of 5-chloromethyl-8-hydroxyquinoline hydrochloride and 300ml of 36wt% triethylamine aqueous solution, reflux at 100°C for 12h, filter and wash to obtain a light yellow sample, Denote it as CTS-HQ. Using CTAB as structure directing agent, TEOS as silicon source, CTS-HQ as carbon source, Ni(CH 3 COO) 2 4H 2 O and RuCl 3 Synthesis of mesoscopic complex C for metal precursors 16 SC-Ru x Ni 100-x . The specific method is: weigh 6.25g CTAB and 46ml H 2 O stirred to dissolve, add 17.5ml EtOH and 17.1ml NH 3 ·H 2 O (25.0wt%), then add 26ml TEOS, add 38g CTS-HQ with a total of 60.8mmol of R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com