Long-chain binary acid continuous crystallization method

A long-chain dibasic acid and long-chain dibasic carboxylic acid technology, applied in solution crystallization, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve low production efficiency, high production cost, unstable product quality, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

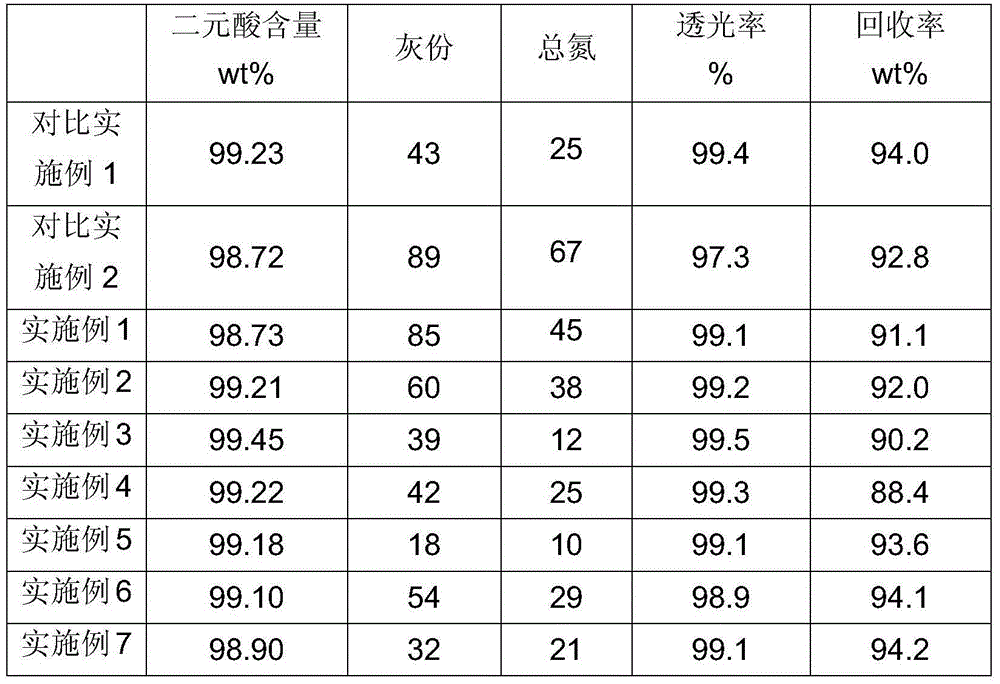

Examples

Embodiment 1

[0099] DC12 fermentation broth was prepared according to the method disclosed in patent document ZL200410018255.7, adding sulfuric acid with a weight concentration of 97% to the fermentation broth to adjust the pH value to 3.0, and heating to 80°C. Add butyl acetate containing 4 times the weight of the long-chain dibasic acid, stir, and directly extract the long-chain dibasic acid in the fermentation broth to the organic phase. Keep at 80°C, separate the organic phase, add 3% activated carbon to the organic phase for decolorization (relative to the weight ratio of the dibasic acid), and filter to obtain the clear liquid.

[0100] The butyl acetate solution enters the continuous crystallization device. The continuous crystallization device is equipped with stirring, and the stirring speed is 50 rpm. The first stage of the continuous crystallization device controls 68±1°C, with an average residence time of 2 hours; the second stage of the continuous crystallization device contr...

Embodiment 2

[0103] According to the membrane filtration method disclosed in the patent document ZL200410018255.7, the DC12 membrane supernatant was prepared, and the solution was added with 97% sulfuric acid by weight to adjust the pH value to 3.0, filtered, and dried to obtain the crude long-chain dibasic acid. Add isoamyl acetate with 3 times the weight of long-chain dibasic acid, stir, keep the temperature at 90°C, add 3% activated carbon for decolorization (relative to the weight ratio of long-chain dibasic acid), and filter to obtain clear liquid.

[0104] The isoamyl acetate solution enters the continuous crystallization device. The continuous crystallization device is equipped with stirring, and the stirring speed is 50 rpm. The first-stage control of the continuous crystallization device is 72±1°C, with an average residence time of 2 hours; the second-stage control of the continuous crystallization device is 57±2°C, with an average residence time of 1 hour; the third-stage control...

Embodiment 3

[0107] According to the membrane filtration method disclosed in the patent document ZL200410018255.7, the DC12 membrane supernatant was prepared, and the liquid was added with 97% sulfuric acid by weight to adjust the pH value to 3.0, filtered, washed, and dried to obtain the crude long-chain dibasic acid. Add isoamyl alcohol with 2.5 times the weight of long-chain dibasic acid, stir, keep the temperature at 75°C, add 3% activated carbon for decolorization (relative to the weight ratio of long-chain dibasic acid), and filter to obtain clear liquid.

[0108] The isoamyl alcohol solution enters the continuous crystallization device. The continuous crystallization device is equipped with stirring, and the stirring speed is 40 rpm. The first stage of the continuous crystallization device is controlled at 55±1°C, with an average residence time of 3 hours; the second stage of the continuous crystallization device is controlled at 48±2°C, with an average residence time of 1 hour; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com