Immune colored silica microsphere

A technology of silica and microspheres, which is applied in the direction of material inspection products, measuring devices, instruments, etc., can solve problems such as dye leakage, colloidal gold color is difficult to control, and restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

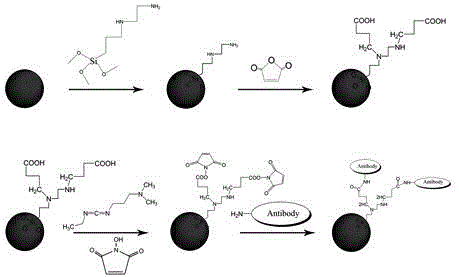

[0011] Activation of colored silica microspheres: wash 100 mg of synthesized colored silica microspheres three times with ultrapure water, disperse them in 20 mL water, and ultrasonically disperse the microspheres for 10 min, then add 1.4 mL of glacial acetic acid and 0.2 mL of The 3-(2-aminoethylamino)propyl-trimethoxysilane was stirred evenly and then continued to shake for 1 h. Wash the reacted microspheres with water for 3 times, disperse them into a mixed solution of 10 mL of succinic anhydride and DMF, and continue to shake and react for 5 h under the condition of nitrogen gas. The microspheres after centrifugation and washing can be stored at 4 °C for later .

[0012] Preparation of immunochromatic silica microspheres: prepare morpholine ethanesulfonic acid buffer (MES) at pH 6.8 with a concentration of 0.1 mol L-1, and add 500 mg of N-hydroxysuccinyl to 5 mL of MES buffer Amine (NHS) and 500 mg of 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide (EDC) for activation of ...

Embodiment 2

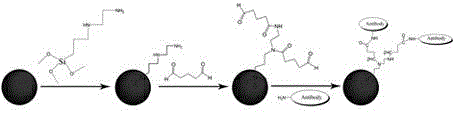

[0014] Aminosilanization of silica particles and antibody labeling Suspend 100mg of colored silica microspheres in 10mL of methanol, add 0.30mL of 3-(2-aminoethylamino)propyl-trimethoxysilane for 15 minutes and then Stir the reaction at room temperature for 6 hours, centrifuge, then use methanol and PBS solution (pH 7.0) for ultrasonic washing and centrifuge to complete the aminosilanization of the colored silica microspheres. Take 10mL of aminosilanized colored silica microsphere suspension and disperse it ultrasonically for 15min, then add 5.0mL of 2.5% glutaraldehyde, stir and react at room temperature for 3h, and then centrifuge to complete the aldylation of the particles. The colored silica microspheres were suspended in 4.0mL PBS solution and ultrasonically dispersed for 15min, then 1.0mL of Enterobacter sakazakii antibody stock solution was added, incubated at 37°C for 1h, centrifuged to obtain Enterobacter sakazakii antibody-colored silica microspheres, and then The pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com