Fenton-like catalyst of graphene coated ferriferrous oxide (Fe3O4) micro-spheres as well as preparation method and application thereof

A technology of alkene-coated ferric tetroxide and catalyst, which is applied in the fields of nanomaterials and environmental science, can solve problems such as consumption, and achieve the effects of reducing cost, good catalytic efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 15% Graphene coated Fe 3 o 4 Preparation of magnetic Fenton-like catalyst:

[0035] (1) Preparation of precursor solution: Weigh 8.08g of ferric nitrate nonahydrate and 0.24g of graphene oxide, put them in 100ml of deionized water, and disperse them ultrasonically for 20min to form Fe 3+ Concentration of 0.2mol / L stable dispersed aqueous solution, ready for use;

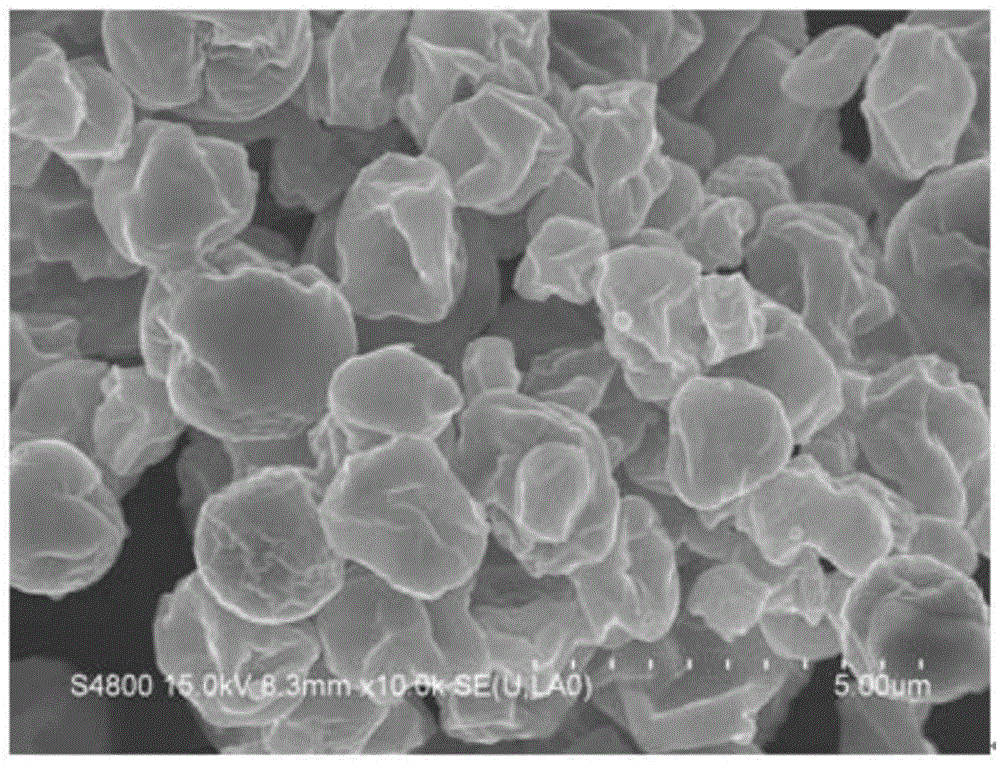

[0036] (2) Send the prepared precursor solution through a syringe pump at a speed of 5ml / min through a gas-assisted atomizing nozzle, and then send it into a spray dryer, wherein the compressed air pressure is 0.4MPa, the temperature at the nozzle is 250°C, and the outlet Temperature is 150 ℃, and the microsphere (as figure 1 shown), its particle size is 1-3 μm, showing a wrinkled and rough shape;

[0037] (3) Place the obtained 15% graphene oxide-coated iron salt precursor microspheres in an Ar gas-protected atmosphere, calcinate at 450°C for 2h, and heat up at a rate of 2°C / min. When cooled to room tempe...

Embodiment 2

[0039] 30% Graphene coated Fe 3 o 4 Preparation of magnetic Fenton-like catalyst:

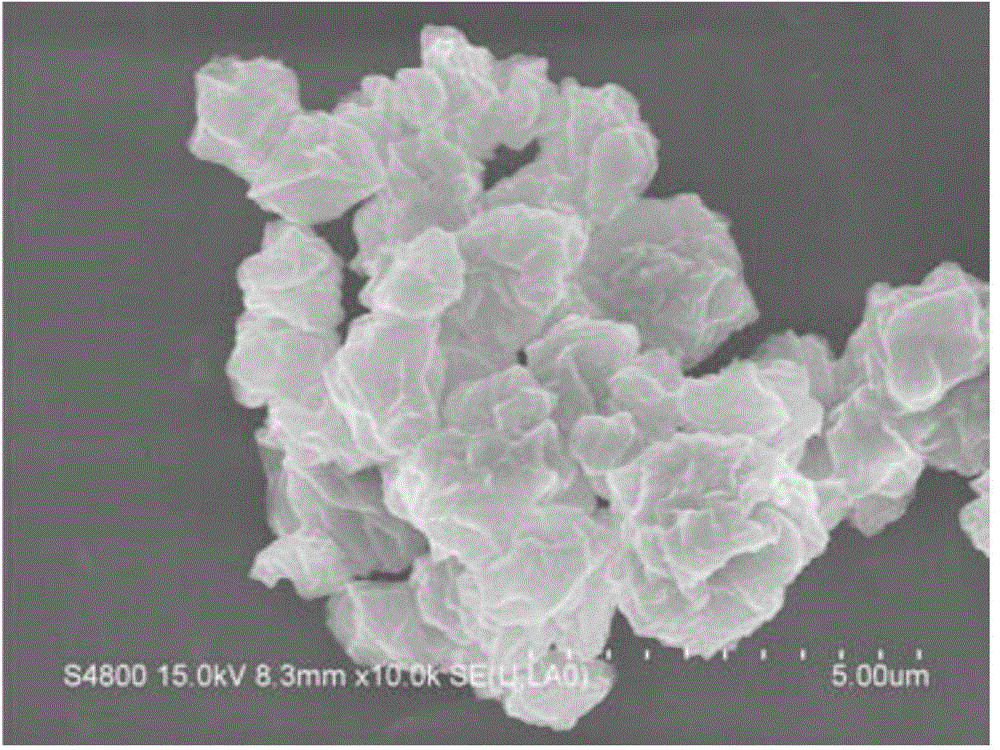

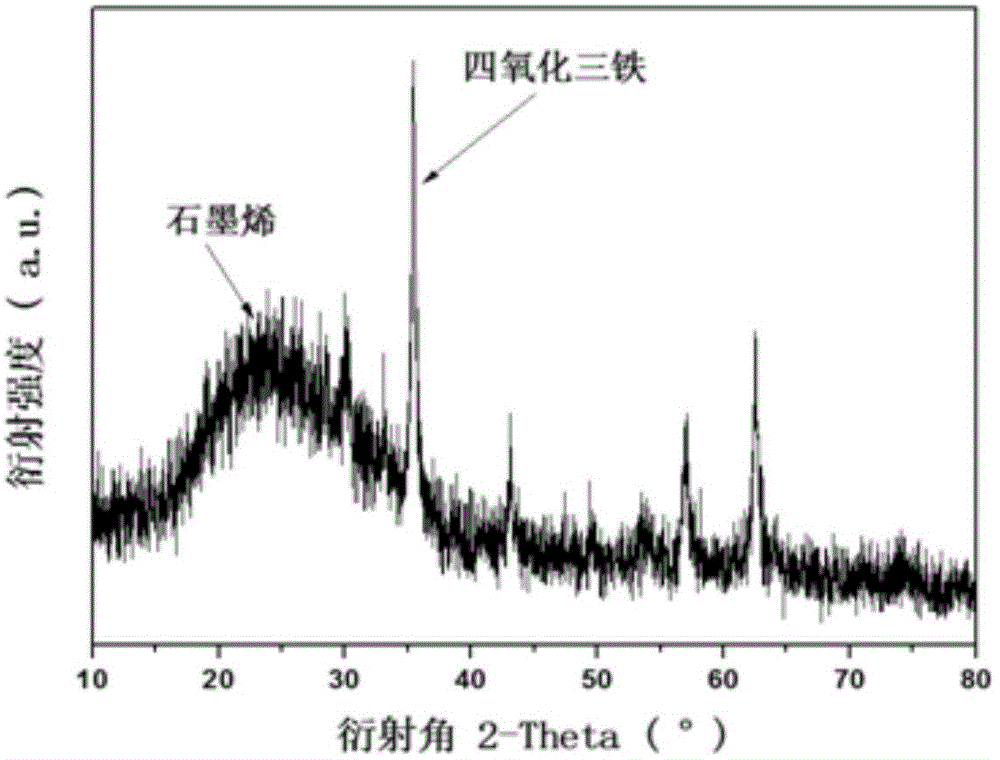

[0040] The graphene oxide content in embodiment 1 is increased to 0.48g, and all the other conditions are unchanged. After calcination in a protective atmosphere, 30% graphene-coated Fe can be obtained 3 o 4 microsphere material. Due to the increase of graphene content, composite microspheres with larger surface wrinkles are formed after self-assembly of gas-phase liquid droplets, and the particle size is about 2 μm (such as figure 2 shown). XRD tests show that the composite microspheres are composed of graphene and iron tetroxide (such as image 3 shown).

Embodiment 3

[0042] 30% Graphene coated Fe 3 o 4 Application of magnetic Fenton catalyst to remove methylene blue molecules:

[0043] (1) Adopt heterogeneous phase similar Fenton method to process containing methylene blue solution, take 250mL Erlenmeyer flask as reactor, methylene blue initial concentration is 10mg / L, get methylene blue solution 100mL, add simultaneously the preparation of embodiment 2 30% Graphene coated Fe 3 o 4 Catalyst 0.1g shake at room temperature for 1h, then add 1g30%H 2 o 2 Oscillate in a constant temperature oscillator with a rotational speed of 150 rpm and a temperature of 25°C.

[0044] (2) Take a sample every 30 minutes, obtain the supernatant by simple magnetic separation, and use a spectrophotometer to detect the concentration of methylene blue in the solution. The results showed that coating Fe with 30% graphene 3 o 4 The effect of the heterogeneous Fenton method of catalyst processing methylene blue solution is very good, and after reacting 210min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com