Novel surface plasma enhanced high-efficiency photocatalytic water splitting composite catalyst

A surface plasmon and composite catalyst technology, applied in the field of energy and environmental materials, can solve the problems of complex steps and low efficiency of photohydrogen production, and achieve the effect of simple device, good water solubility and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] (1) Preparation method of sulfur precursor solution

[0036] Take 3mL of n-dodecanethiol and 7mL of toluene, add them in turn to a 20mL polytetrafluoroethylene reactor, stir evenly to form a solution c, weigh 38.79mg of sulfur powder and add it to the above solution c, stir at room temperature for 2min, seal it, and React in an oven at 100°C for 15 hours, and take it out as a sulfur precursor for later use.

[0037] (2) The preparation method of selenium precursor solution

[0038] Take 3mL of octadecene and 7mL of toluene, add them in turn to a 20mL polytetrafluoroethylene reactor, stir evenly to form a solution d, weigh 134.5mg of selenium dioxide and add it to the above solution d, stir at room temperature for 2min, seal it, and It was reacted in an oven at ℃ for 15 hours, and then taken out as a selenium precursor for later use.

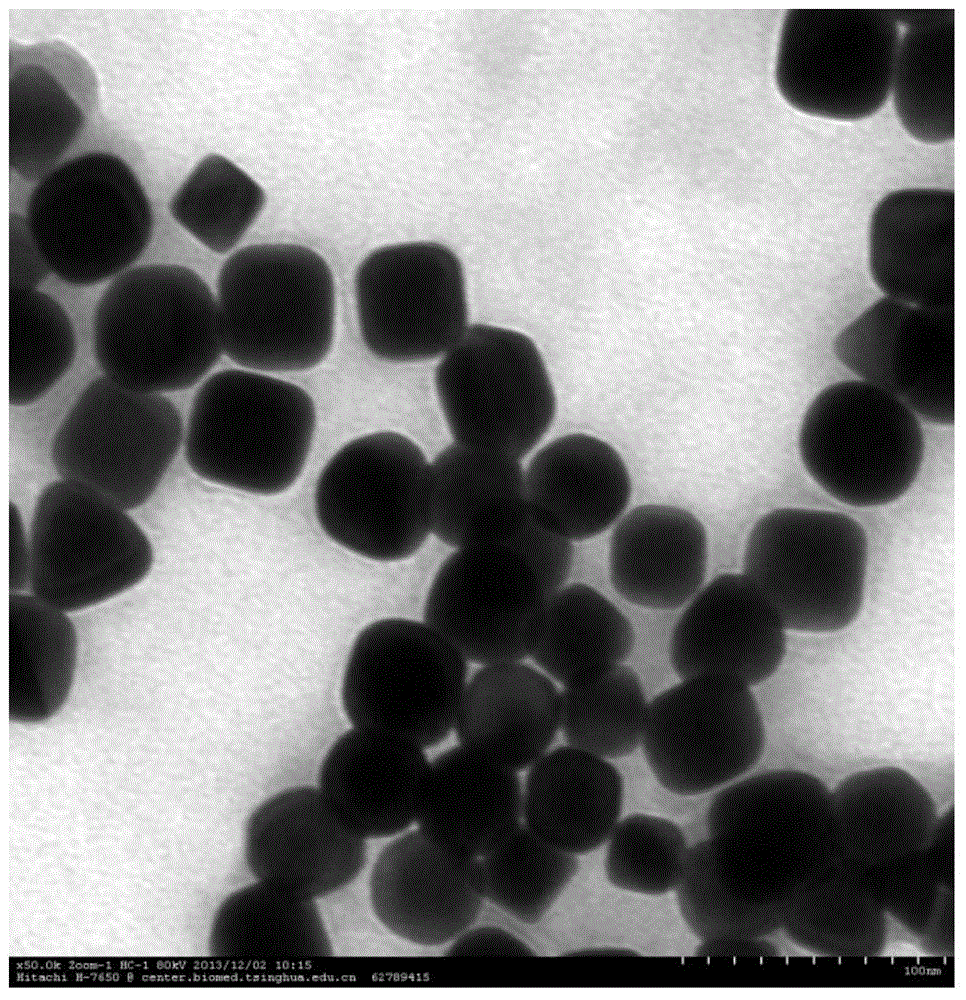

[0039] (3) Preparation method of gold nanoparticle hydrosol

[0040] Take 1.25mL 0.001mol / L chloroauric acid solution and 2.5mL 0.15mo...

Embodiment 1

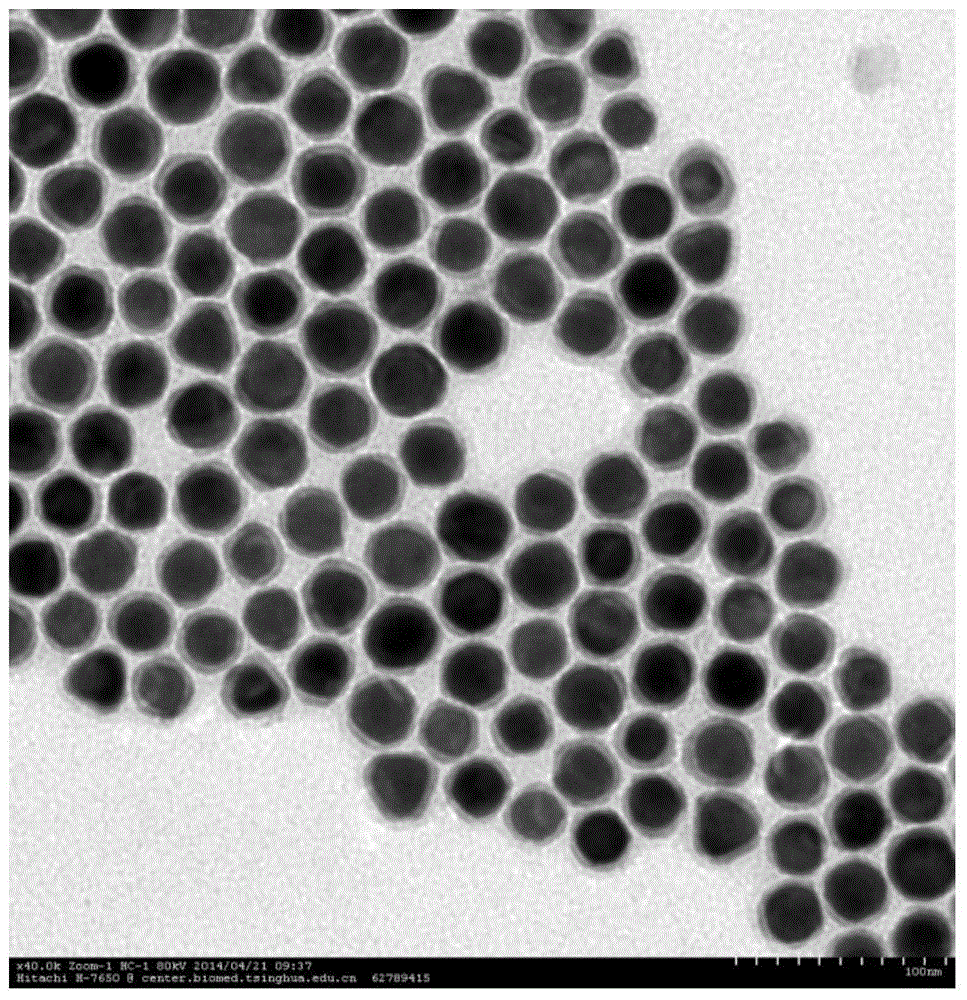

[0044] (1) Take 30mL of the aqueous sol of the gold nanoparticles in a 50mL centrifuge tube, centrifuge and wash at 7000rpm for 10min, discard the supernatant, and redisperse the lower gold nanoparticles in 10mL of 0.025mol / L hexadecyltrimethyl Ammonium bromide (CTAB) solution, add 0.7mL 0.1mol / L ascorbic acid (A.A), 0.2mL 0.01mol / L silver nitrate (AgNO 3 ) solution, adding 1.0mL of 0.1mol / L sodium hydroxide (NaOH) to adjust the pH of the solution to 10, and standing in a water bath at 30°C for 1h to obtain the Au / Ag core-shell structure nanocrystalline sol with a concentration of 0.005mol / L.

[0045] (2) Take 15mL of the above-mentioned Au / Ag core-shell structure nanocrystalline sol and add it to a 20mL polytetrafluoroethylene reactor, then add 60uL of the sulfur precursor solution, mix well, seal it, and put it in an oven at 80°C for reaction At the end of 1h, wash with deionized water at a volume ratio of 1:1, centrifuge at 7000rpm for 10min, discard the supernatant, and ...

Embodiment 2

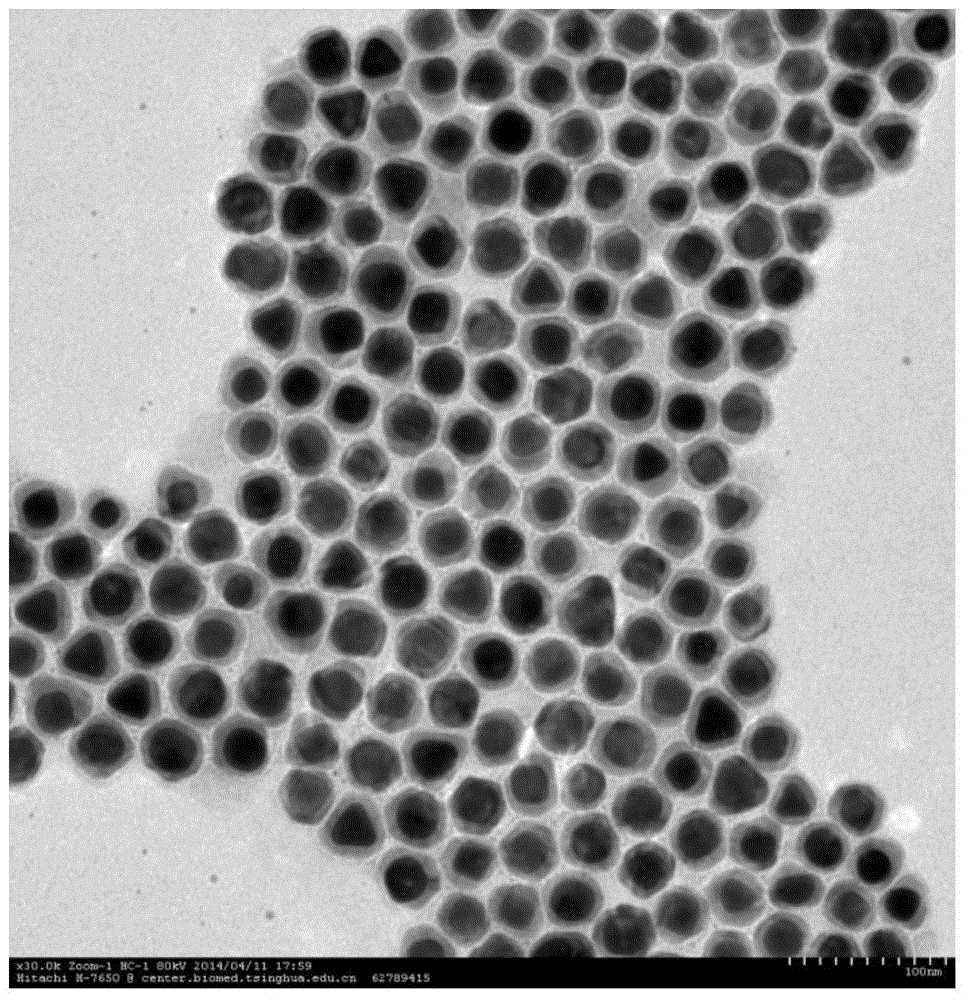

[0049] (1) Take 30mL of the aqueous sol of the gold nanoparticles in a 50mL centrifuge tube, centrifuge and wash at 7000rpm for 10min, discard the supernatant, and redisperse the lower gold nanoparticles in 10mL of 0.025mol / L hexadecyltrimethyl Ammonium bromide (CTAB) solution, add 0.7mL 0.1mol / L ascorbic acid (A.A), 0.35mL 0.01mol / L silver nitrate (AgNO 3 ) solution, adding 1.0mL of 0.1mol / L sodium hydroxide (NaOH) to adjust the pH of the solution to 10, and standing in a water bath at 30°C for 1h to obtain the Au / Ag core-shell structure nanocrystalline sol with a concentration of 0.005mol / L.

[0050] (2) Take 15mL of the above-mentioned Au / Ag core-shell structure nanocrystalline sol and add it to a 20mL polytetrafluoroethylene reactor, then add 80uL of the sulfur precursor solution, mix well, seal it, and put it in an oven at 80°C for reaction At the end of 1h, wash with deionized water at a volume ratio of 1:1, centrifuge at 7000rpm for 10min, discard the supernatant, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com