Automatic melting speed control system of vacuum arc remelting furnace

A vacuum self-consumption arc and automatic control system technology, applied in the field of electric arc furnace metallurgy industry, can solve the problems of low control precision, low first-time yield, high energy consumption, etc., achieve accurate calculation, convenient installation and layout, and low input cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

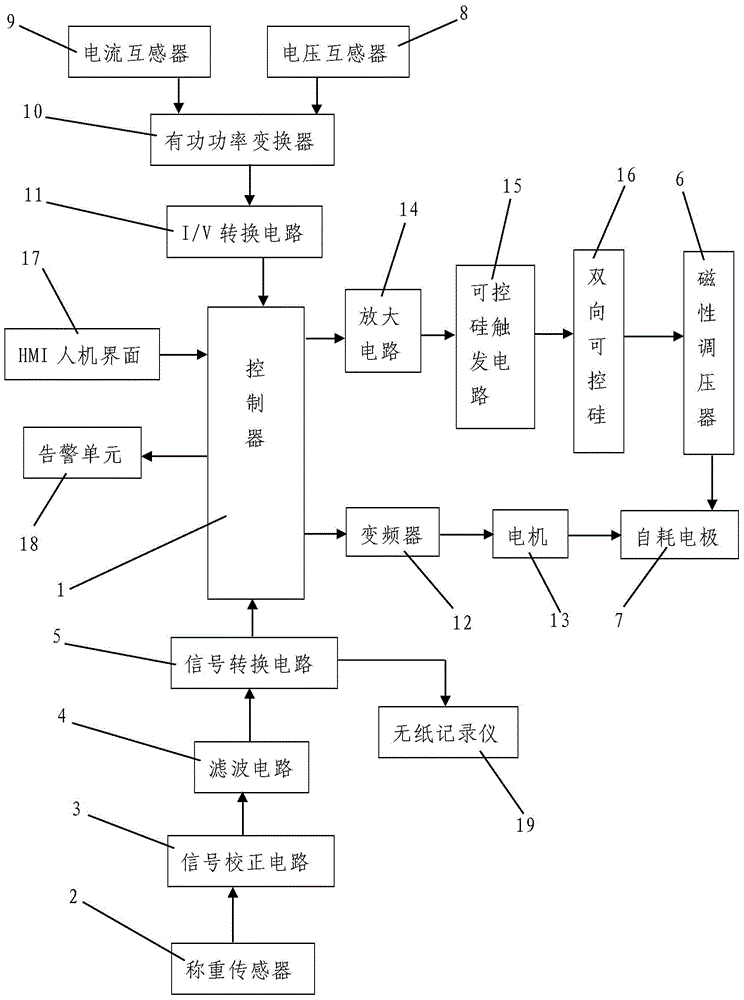

[0025] Such as figure 1 As shown, the present invention includes a controller 1, a melting speed measurement system, a power detection unit, an electrode lifting control unit, an arc current adjustment unit, an HMI connected to the controller 1 and used for inputting melting speed curves and current and voltage parameters A machine interface 17 and an alarm unit 18 connected with the controller 1; the melting rate measurement system includes a load cell 2 installed on the electrode rod load-bearing mechanism and used for real-time measurement of the current remaining electrode weight, and a load cell 2 corresponding to the load cell 2 Connected to a signal correction circuit 3 for correcting weighing data, a filter circuit 4 connected to the signal correction circuit 3, and a signal conversion circuit 5 for converting the current remaining electrode weight signal into an electrode melting speed signal; The power detection unit includes a voltage detection unit 8 and a current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com