Method for producing clamp plate through lignin adhesives

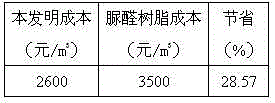

A lignin glue and adhesive technology, which is applied in lignin adhesives, wooden veneer joints, adhesives, etc., can solve the problems of poor quality adhesives, poor product quality, and affecting people's safety. Achieve the effects of superior moisture resistance, low production cost, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

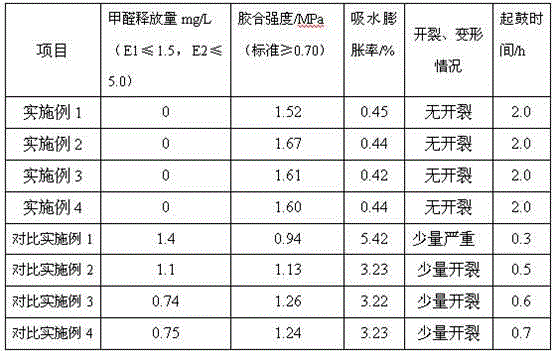

Examples

Embodiment 1

[0018] The production process of the lignin adhesive is as follows: In order to reduce the cost of raw materials, the pulp black liquor pulped by the alkali cooking method using bagasse as raw material is processed to obtain lignin with a content of more than 85%, and 70wt% lignin is added to the lignin Sulfuric acid, after stirring evenly, heat up to 140-160°C, sulfonation reaction for 1-2 hours; through the central circulation tube evaporator, the circulation speed is 0.4m / s-0.5m / s, and the moisture content of the output is controlled to 30wt% , precipitation, filtered and dried to a water content of 15wt%; add phenol according to lignin:phenol 1:1 (weight ratio), control the temperature at 85-95°C, keep the temperature for 1 hour, and finally adjust the pH with 30wt% sodium hydroxide to 6.5-7.0; 40-60 parts of the obtained reactant; add 15-20 parts of potato starch; 1-5 parts of silane coupling agent; 8-15 parts of aliphatic polyurethane acrylate; 3-5 parts of polyisocyanate...

Embodiment 2

[0021] Select veneers of the same size to make 5 layers of plywood, and coat the veneer with the lignin adhesive prepared in Example 1, and the amount of glue applied is 250g / m 2 , pre-pressing, the conditions are: temperature: 100°C, pressure: 0.7Kpa, time: 0.6min / mm; hot pressing, the conditions are: temperature: 150°C, pressure: 0.8Kpa, time: 0.7min / mm; stacking maintenance, The specific method is as follows: at room temperature, set up the bonded plywood layer by layer with wooden strips, and the upper and lower layers of wooden strips are arranged in the shape of "well" for 28 hours; Low wood surface, polished wood surface, paste aluminum oxide wear-resistant paper on the wood surface, hot press at 170°C, pressure 2.0MPa, heat dissipation finishing, edge beating, that is.

Embodiment 3

[0023] Select veneers of the same size to make 7 layers of plywood, and coat the veneer with the lignin adhesive prepared in Example 1, and the amount of glue applied is 280g / m 2 , pre-pressing, the conditions are: temperature: 100°C, pressure: 0.8Kpa, time: 0.8min / mm; hot pressing, the conditions are: temperature: 150°C, pressure: 1.0Kpa, time: 0.9min / mm; stacking maintenance, The specific method is: at room temperature, set up the bonded plywood layer by layer with wooden strips, and the upper and lower layers of wooden strips are arranged in the shape of a "well" for 30 hours; Low wood surface, polished wood surface, paste aluminum oxide wear-resistant paper on the wood surface, hot press at 170°C, pressure 2.5MPa, heat dissipation finishing, beating, and you get it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com