Universal method for controllable growth of nano structure on single-layer graphene film

A single-layer graphene, nanostructured technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of inability to change the morphology, density and distribution uniformity of nanoparticles, limiting scale , the preparation process is complicated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

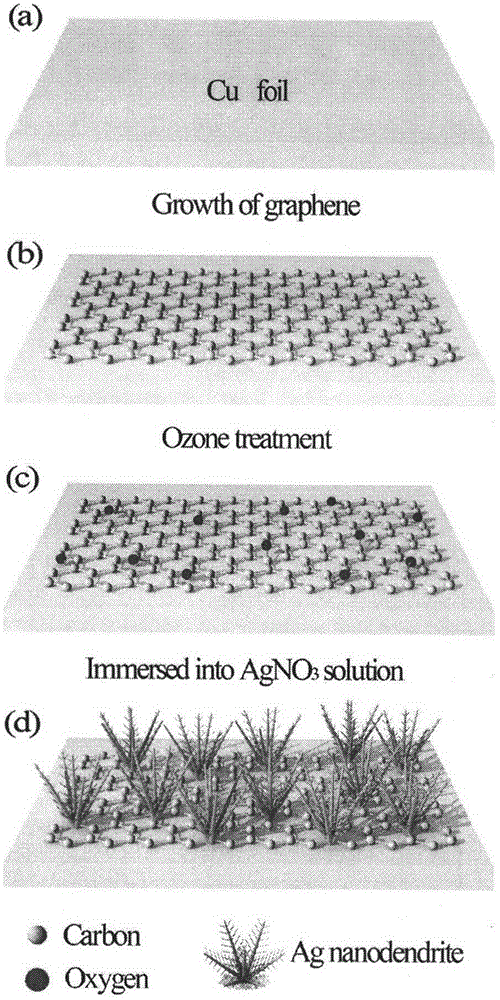

[0020] Technical thinking of the present invention is:

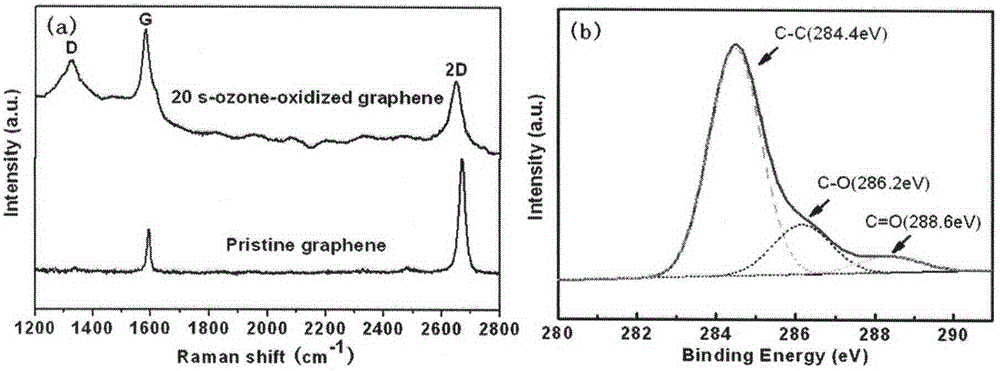

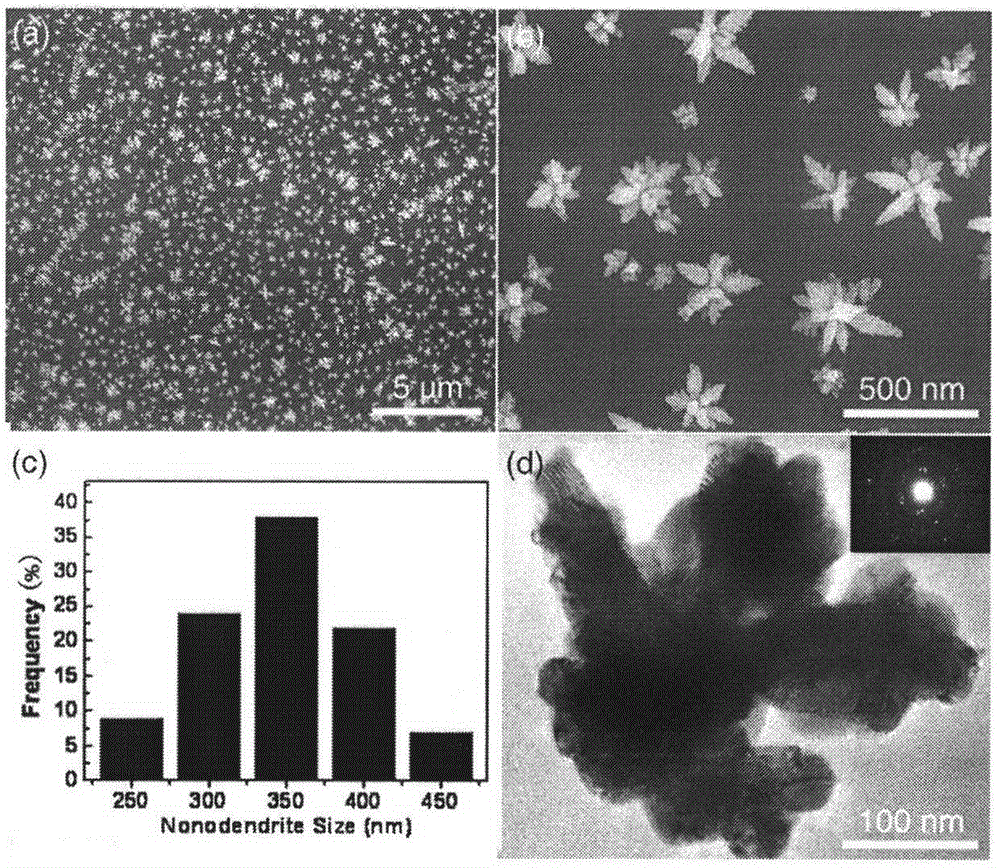

[0021] In order to overcome the technical difficulties existing in the prior art, the present invention proposes for the first time the idea of applying oxygen functional groups on graphene planes as nucleation sites. In recent years, the controllable growth of high-quality graphene films by CVD process has matured, which provides a better choice for further exploiting the advantages of graphene-based composite materials. Taking the single-layer graphene film grown by CVD on Cu foil as a typical example, based on the idea of ozone treatment, we synthesized silver nanodendrites in situ under control. The process route is to first use ozone to treat the graphene film, add oxygen functional groups evenly and dispersedly on the graphene plane as the nucleation site, and then soak the treated substrate in the silver salt solution for galvanic reaction to obtain graphite Alkenyl silver nanostructured composites. And by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com