Electrochemical preparation method of amorphous silicon dioxide

A silica and amorphous technology, which is applied in the chemical industry, electrolytic process, electrolytic components, etc., can solve the problems of high purity of silica products, high equipment requirements, and low product purity, so as to reduce the preparation cost and synthesize the amount Large, high-purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

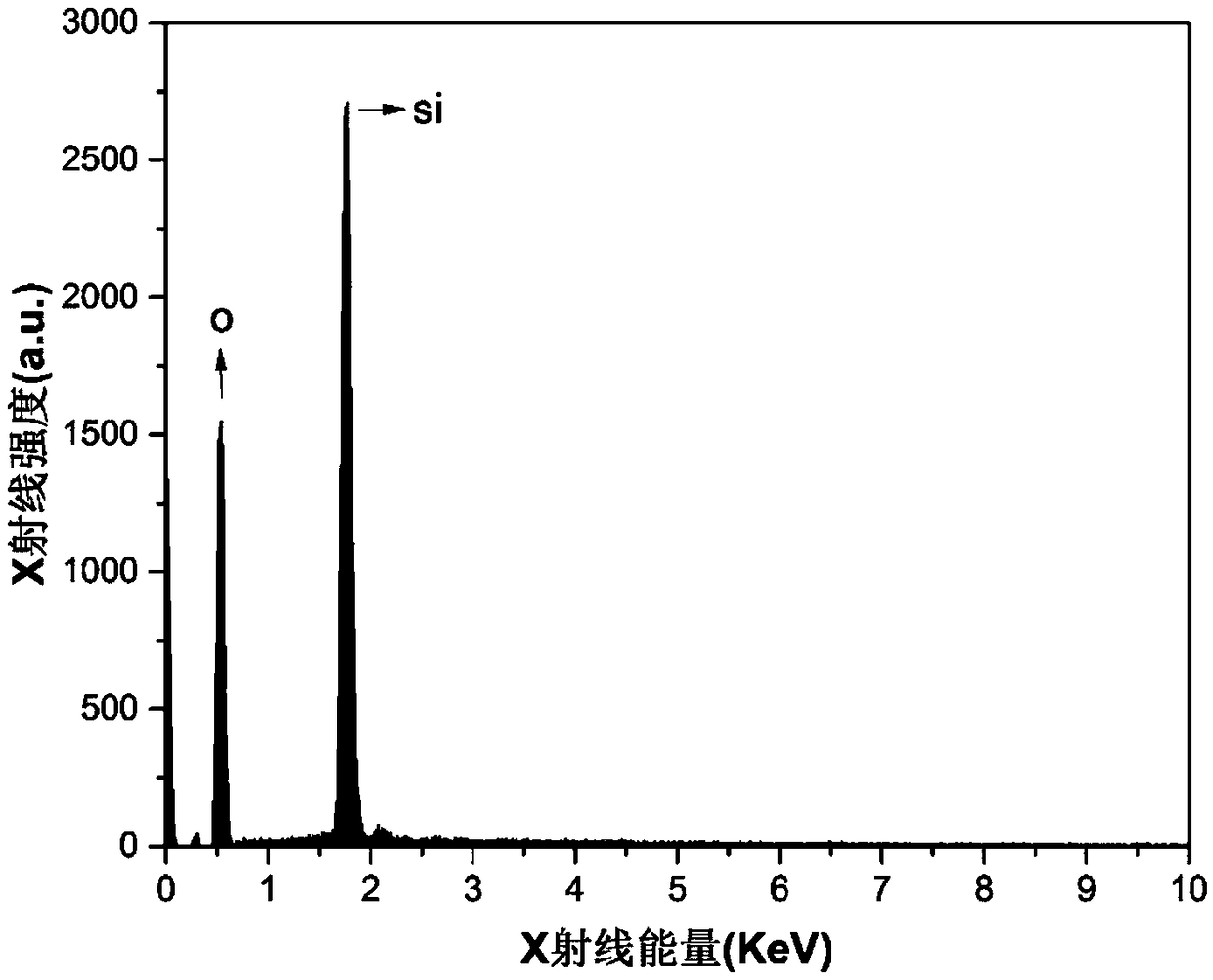

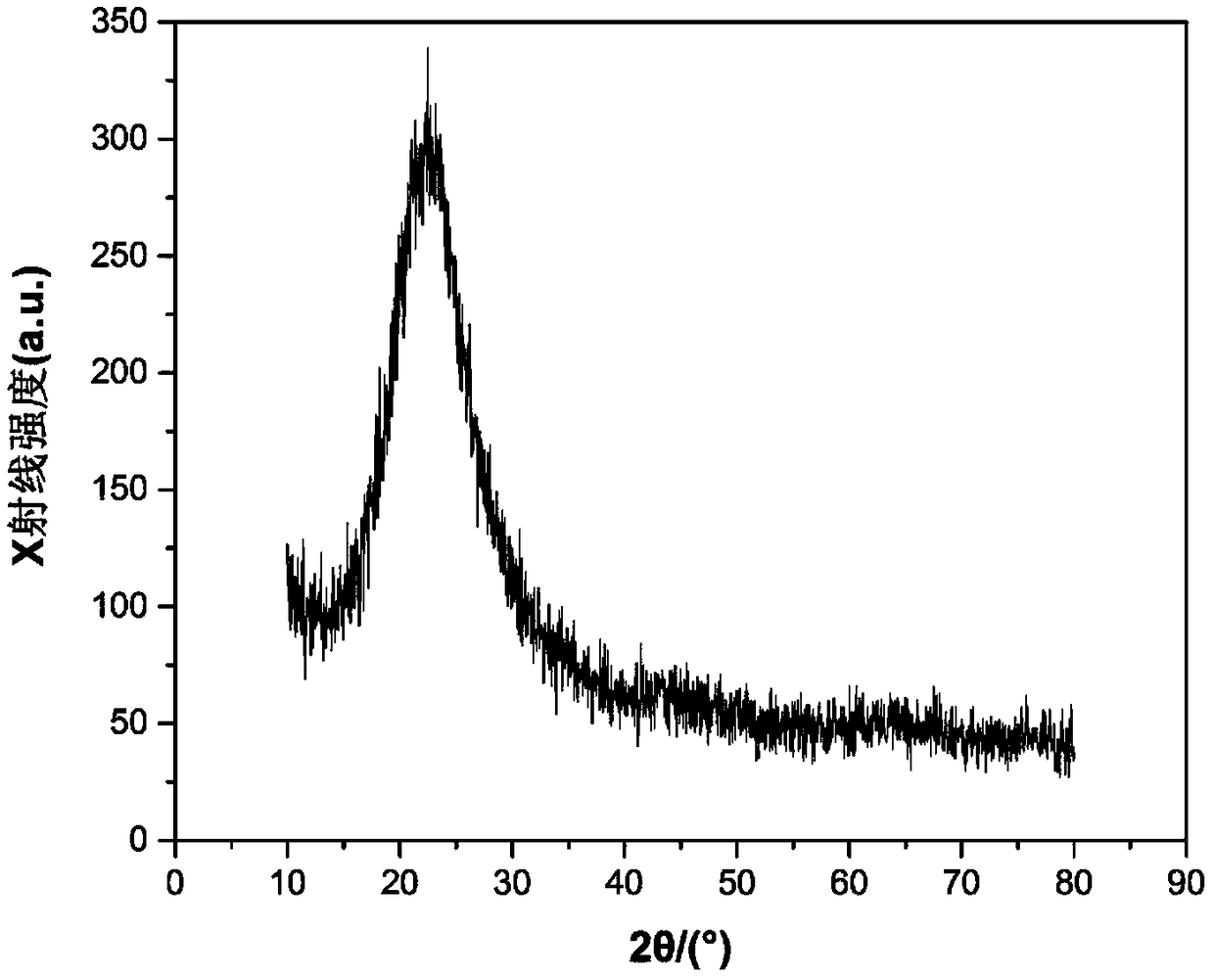

[0023] The invention provides an electrochemical preparation method of amorphous silicon dioxide, comprising the following steps: using cheap sodium silicate solution as a silicon source, adopting a cationic membrane electrolysis method to prepare a silicon dioxide precursor; The silicon precursor is dried until there is no solution, and then ground; the ground silicon dioxide precursor is subjected to multiple centrifugal filtration to make the pH value close to neutral to remove the remaining H + And sodium silicate, after drying and grinding, amorphous silica with high purity and no impurity phase can be obtained.

[0024] In the present invention, the preparation of the silicon dioxide precursor by cationic electrolysis mainly includes the following steps: using sodium silicate aqueous solution as the anolyte, hydrochloric acid as the catholyte, and an inert electrode as the electrode, adopting a constant current / constant voltage method in a bipolar chamber The sodium sili...

Embodiment

[0029] (1) The electrochemical preparation process of silicon dioxide precursor mainly includes the following steps: 0.1mol / L sodium silicate aqueous solution is used as anolyte, 0.1mol / L hydrochloric acid is used as catholyte, and DSA titanium mesh inert electrode is used as The electrode uses 20V constant voltage to electrolyze the sodium silicate solution in the electrolytic cell of the bipolar chamber, and conduct electrolysis at room temperature until all Na+ ions are transferred to the cathode chamber;

[0030] (2) The process of drying and grinding the silicon dioxide precursor obtained after electrolysis mainly includes the following steps: continuously vacuum-dry the silicon dioxide precursor obtained after electrolysis at 100°C in a vacuum drying oven until no solution exists ; Mechanically grinding the dried silica precursor;

[0031] (3) The process of centrifugally filtering the ground silica precursor mainly includes the following steps: placing the ground silica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com