Method for preparing modified pseudo-boehmite

A pseudo-boehmite and modification technology, applied in the field of inorganic material preparation, can solve the problems such as the inability of additives to promote alumina, the inability to effectively exert modification performance, side reactions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

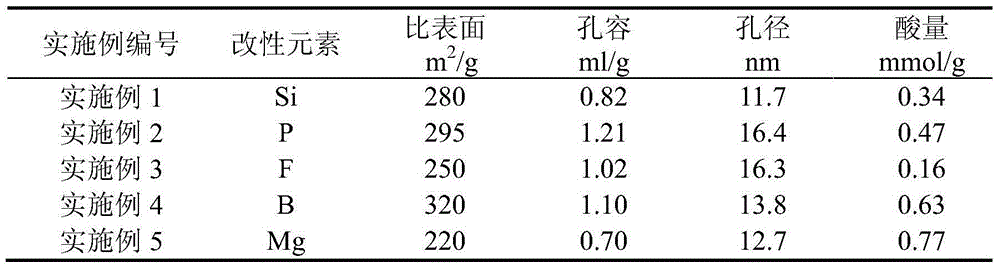

[0029] Add 500g of activated alumina, 500g of aluminum hydroxide and 106g of water glass in 8kg of deionized water under the condition of sufficient stirring, and use a high-shear mixer to carry out homogeneous shearing treatment to obtain a slurry with an average particle size of 9.6 μm, and use 20% Adjust the pH to 11 with sodium hydroxide solution, then transfer to a high-pressure reactor and react at 180°C for 24 hours. After the reaction, the resulting slurry is separated from solid and liquid, washed with deionized water, and the obtained filter cake is dried in an oven at 120°C for 6 hours. , and pulverized to obtain silicon-modified pseudo-boehmite powder, whose physical and chemical properties are shown in Table 1.

Embodiment 2

[0031] Add 800g of activated alumina, 200g of aluminum hydroxide and 120g of sodium hexametaphosphate to 8kg of deionized water in turn under the condition of sufficient stirring, and use a ball mill to carry out homogenization and refinement treatment to obtain a slurry with an average particle size of 2.6 μm. The sodium oxide solution adjusted the pH to 10, then transferred to a high-pressure reactor and reacted at 150°C for 48 hours. After the reaction, the obtained slurry was separated from solid and liquid, washed with deionized water, and the obtained filter cake was dried in an oven at 120°C for 6 hours. The phosphorus-modified pseudo-boehmite powder was obtained by crushing, and its physical and chemical properties are shown in Table 1.

Embodiment 3

[0033] Add 600g of activated alumina, 300g of aluminum hydroxide and 8g of ammonium fluoride to 8kg of deionized water in turn under the condition of sufficient stirring, and use a ball mill to carry out homogeneous shearing treatment to obtain a slurry with an average particle size of 0.8 μm, and use 20% hydrogen The sodium oxide solution adjusted the pH to 11, and then transferred to a high-pressure reactor to react at 100°C for 48 hours. After the reaction, the obtained slurry was separated from solid and liquid, washed with deionized water, and the obtained filter cake was dried in an oven at 120°C for 6 hours. The fluorine-modified pseudo-boehmite powder was obtained by pulverization, and its physical and chemical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com