Method for concentrating high-concentration brine

A technology for concentrated brine and concentrated water, which is applied in general water supply conservation, chemical instruments and methods, multi-stage water treatment, etc. The effect of flocculation and sedimentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

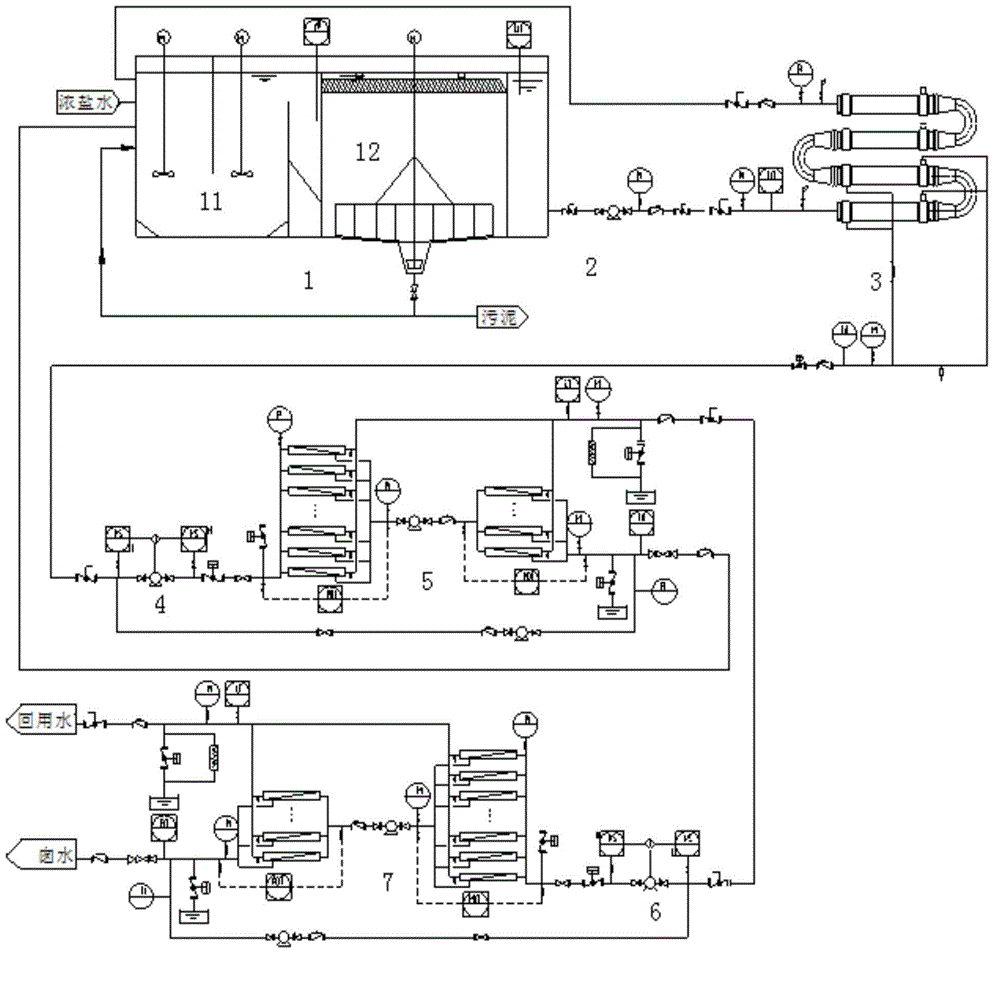

[0023] The method flow chart of the present invention (high concentrated brine concentration method) is as figure 1 shown.

[0024] figure 1 Among them, the present invention is a fully automatic control method, mainly composed of 1-circulation high-efficiency precipitation, 2-circulation pump, 3-circulation ultrafiltration, 4-nanofiltration feed water pump, 5-nanofiltration, 6-high salt reverse osmosis feed water pump, 7- High-salt reverse osmosis and other units, each area is closely connected, and equipped with agitator and mud pump.

[0025] The main material of the device of the present invention is carbon steel for anticorrosion, three coats of epoxy coal tar pitch paint for the interior, two coats of epoxy coal tar pitch paint for the exterior, and two coats of topcoat.

[0026] The concentrated brine first enters the stirring zone of the circulating high-efficiency sedimentation zone. The water inlet adopts a lateral water inlet structure, and the raw water flows int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com