Method for quickly relieving activity inhibition of heavy metals on anaerobic ammonia oxidation sludge

An anaerobic ammonia oxidation and activity inhibition technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of cell membrane damage, long recovery time, and complex heavy metal-containing wastewater components To achieve the effect of improving denitrification activity and alleviating the inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

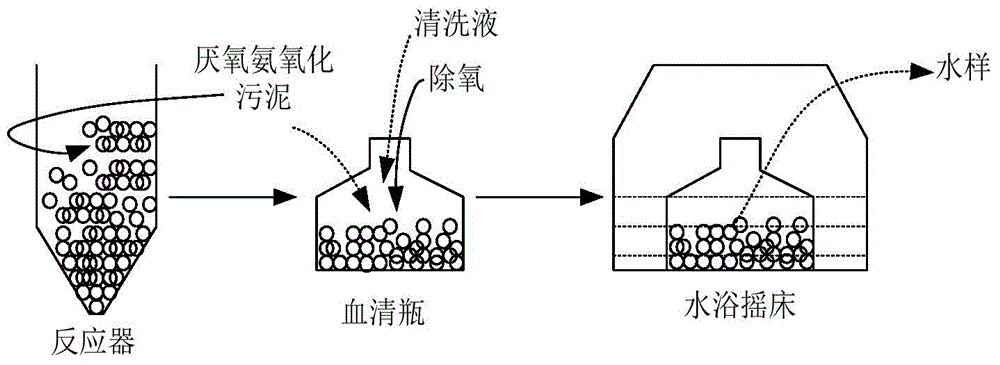

[0026] refer to figure 1 The flow shown is a test for rapidly activating the activity of heavy metal-contaminated anammox sludge.

[0027] Test sludge: taken from an upflow anaerobic sludge bed reactor (effective volume 1.0L, sludge concentration 20gVSS / L) operated in a constant temperature room at 35°C for a long time, when the final concentration of copper ions is 5mg / L, 8mg / L, 10mg / L, and 12mg / L were operated for two weeks, and the final total nitrogen removal rate (NRR) was 0.05kgN m -3 d -1 .

[0028] Take the mud and wash it with deionized water for 5 times, measure 10ml of the washed sludge (copper ion content is 15.7gCu / gSS) with a graduated cylinder, add it to a serum bottle with a stopper, add 110ml of cleaning solution, and use 2M dilute hydrochloric acid and 1M NaOH Adjust the pH of the aqueous solution to 7.40-7.60. Fill the serum bottle with argon gas for deoxygenation for 10 minutes, seal it, then place it in a constant temperature shaker at 35°C, shake it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com