Zinc oxide semiconductor ceramic chip for lightning protection and preparation method for zinc oxide semiconductor ceramic chip

A technology of semi-conductive ceramic and zinc oxide, applied in the field of zinc oxide semi-conductive ceramic sheet and its preparation, can solve the problems of increasing the volume of surge protector, large thickness and size, inconvenient installation, etc. The effect of strong deterioration ability and small leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

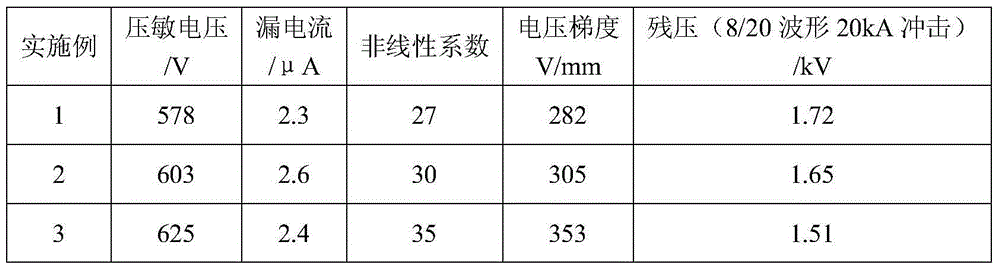

Examples

Embodiment 1

[0026] (1) Take analytically pure raw materials, after drying, weigh them according to the following molar percentages, and configure them into zinc oxide semiconducting ceramic chip mixed powder, wherein the content of ZnO is 15mol%, Bi 2 o 3 The content is 2.5mol%, Sb 2 o 3 The content is 5mol%, Co 2 o 3 The content is 2.5mol%, MnO 2 The content is 2.5mol%, Cr 2 o 3 The content is 2.5mol%;

[0027] (2) In the above-mentioned mixed powder of zinc oxide semiconducting tiles prepared, add deionized water as a dispersant, add a PVA aqueous solution with a concentration of 8wt% as a binding agent by 5wt% of the raw material weight, and use agate quality Grinding balls are used for ball milling, and the ball milling time is 5 hours;

[0028] (3) send the ball-milled raw materials into an oven for drying, the drying temperature is 120°C, and the drying time is 22 hours;

[0029] (4) After pulverizing the dried powder with a mortar, pass through a 20-mesh sieve, and pre-bur...

Embodiment 2

[0035] (1) Take analytically pure raw materials, after drying, weigh them according to the following molar percentages, and configure them into zinc oxide semiconducting ceramic chip mixed powder, wherein the content of ZnO is 15mol%, Bi 2 o 3 The content is 2.5mol%, Sb 2 o 3 The content is 5mol%, Co 2 o 3 The content is 2.5mol%, MnO 2 The content is 2.5mol%, Cr 2 o 3 The content is 2.5mol%.

[0036] (2) in the zinc oxide mixed powder of above-mentioned preparation, add deionized water as dispersant, add the PVA aqueous solution that concentration is 10wt% as binding agent by 6wt% of raw material weight, the grinding ball of agate quality carries out ball milling, The ball milling time was 4 hours.

[0037] (3) send the ball-milled raw materials into an oven for drying, the drying temperature is 135°C, and the drying time is 23 hours;

[0038] (4) The dried powder is pulverized with a mortar, passed through a 40-mesh sieve, and the sieved powder is pre-calcined in air...

Embodiment 3

[0044] (1) Take analytically pure raw materials, after drying, weigh them according to the following molar percentages, and configure them into zinc oxide semiconducting ceramic chip mixed powder, wherein the content of ZnO is 15mol%, Bi 2 o 3 The content is 2.5mol%, Sb 2 o 3 The content is 5mol%, Co 2 o 3 The content is 2.5mol%, MnO 2 The content is 2.5mol%, Cr 2 o 3 The content is 2.5mol%.

[0045] (2) in the zinc oxide mixed powder of above-mentioned preparation, add deionized water as dispersant, add the PVA aqueous solution that concentration is 12wt% as binding agent by 6wt% of raw material weight, the grinding ball of agate quality carries out ball milling, The ball milling time was 6 hours.

[0046] (3) send the ball-milled raw materials into an oven for drying, the drying temperature is 150°C, and the drying time is 24 hours;

[0047] (4) The dried powder is pulverized with a mortar, passed through a 60-mesh sieve, and the sieved powder is pre-calcined in air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com