A kind of preparation method of in-situ reaction film-forming pore-type controlled-release fertilizer

An in-situ reaction and controlled-release fertilizer technology, which is applied in the direction of fertilizer mixture, layered/coated fertilizer, application, etc., can solve the problems that the nutrient release effect cannot be fully realized according to demand, the release amount is fixed, and the nutrient release channel is single. , to achieve the effect of benefiting crop growth and shortening the fertilizer effect period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 4% sodium bentonite of the total weight of the coating skeleton substance, and the thickness of the coating is 6%. The coating skeleton substance is a vegetable oil polyol and a curing agent, and the weight ratio of the two is 1:1; the curing agent is poly isocyanate.

[0042] Weigh each component by weight as follows:

[0043] Vegetable oil polyol (castor oil and epoxidized soybean oil blend): 300 g

[0044] Curing agent (polymethylene polyphenyl diisocyanate): 300 g

[0045] Porogenic material (sodium bentonite): 24 g

[0046] Urea (3 mm≤d≤5 mm): 10 Kg

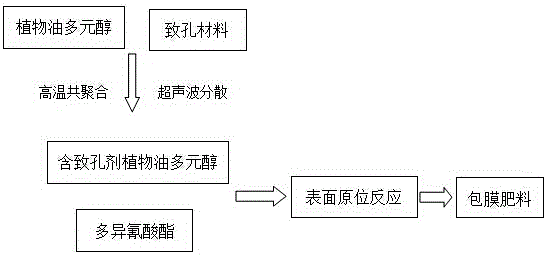

[0047] The schematic diagram of the preparation process of the coated controlled-release fertilizer of the present invention refers to the attached figure 1 , including the following steps:

[0048] S1: Vegetable oil polyol and polyisocyanate were weighed according to the weight ratio of vegetable oil polyol to polyisocyanate 1:1, and porogenic materials were added to vegetable oil polyol.

[0049] S2: First...

Embodiment 2

[0052] Add the sodium bentonite of 8% of the total weight of the coating skeleton substance, and the thickness of the coating is 6%. The coating skeleton substance is vegetable oil polyol and curing agent, and the weight ratio of the two is 1:1; isocyanate.

[0053] Weigh each component by weight as follows:

[0054] Vegetable oil polyol (castor oil and epoxidized soybean oil blend): 300 g

[0055] Curing agent (polymethylene polyphenyl diisocyanate): 300 g

[0056] Porogenic material (sodium bentonite): 48 g

[0057] Urea (3 mm≤d≤5 mm): 10 Kg

[0058] The schematic diagram of the preparation process of the coated controlled-release fertilizer in this embodiment refers to the attached figure 1 Shown, step is with embodiment 1, and envelope thickness is 6%.

Embodiment 3

[0060] Add magnesium carbonate of 4% of the total weight of the coating skeleton substance, and the thickness of the coating is 6%. The coating skeleton substance is vegetable oil polyol and curing agent, and the weight ratio of the two is 1:1; the curing agent is polyisocyanate .

[0061] Weigh each component by weight as follows:

[0062] Vegetable oil polyol (castor oil and epoxidized soybean oil blend): 300 g

[0063] Curing agent (polymethylene polyphenyl diisocyanate): 300 g

[0064] Porogenic material (magnesium carbonate): 24 g

[0065] Urea (3 mm≤d≤5 mm): 10 Kg

[0066] The schematic diagram of the preparation process of the coated controlled-release fertilizer in this embodiment refers to the attached figure 1 Shown, step is with embodiment 1, and envelope thickness is 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com