Preparation method of etamsylate

A technology of sulfoethylamine and hydroquinone, which is applied in the preparation of sulfonate, the preparation of organic compounds, the preparation of amino compounds, etc., can solve the problems of incomplete reaction of p-benzoquinone, high solubility, low toxicity, etc. The effect of protecting environmental quality scores, reducing costs and pollution, and designing simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

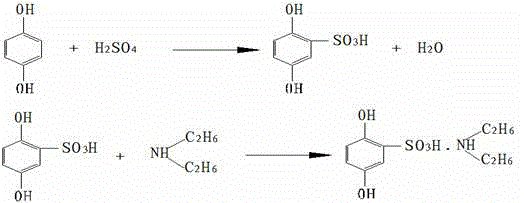

[0018] A kind of preparation method of phensulfame, it is characterized in that, it comprises the steps:

[0019] Step 1: Sulfonation: Add 50g of hydroquinone and 48g of concentrated sulfuric acid into the same three-necked bottle respectively, then heat in a water bath, and slowly raise the temperature until the hydroquinone is completely melted into a liquid state, and then stir the solution. , keep the three-necked bottle warm for 1 hour, after one hour keep the temperature down to 40°C, then add 100g of distilled water and 2g of activated carbon in turn to raise the temperature to 55°C, decolorize and stir for 30min, then filter to get 2,5-dihydroxy Benzenesulfonic acid solution;

[0020] Step 2: Salt formation: Pour the filtrate obtained in step 1 into another three-necked flask, cool the filtrate to 25°C, and then slowly add 2,5-dihydroxybenzenesulfonic acid to diethylamine in a mass ratio of 2 : the diethylamine of 1, after reaction finishes, cooling crystallization, t...

Embodiment 2

[0024] A kind of preparation method of phensulfame, it is characterized in that, it comprises the steps:

[0025] Step 1: Sulfonation: Add 60g of hydroquinone and 60g of concentrated sulfuric acid into the same three-necked bottle respectively, then heat in a water bath, and slowly raise the temperature until the hydroquinone is completely melted into a liquid state, and then stir the solution. , keep the three-neck flask warm for 1 hour, and then lower the temperature to 40°C after one hour of heat preservation, then add 120g of distilled water and 2.4g of activated carbon in turn to raise the temperature to 55°C, decolorize and stir for 30min, then filter to obtain 2,5-di Hydroxybenzenesulfonic acid solution;

[0026] Step 2: Salt formation: Pour the filtrate obtained in step 1 into another three-necked flask, cool the filtrate to 25°C, and then slowly add 2,5-dihydroxybenzenesulfonic acid to diethylamine in a mass ratio of 1 : the diethylamine of 1, after reaction finishes...

Embodiment 3

[0030] A kind of preparation method of phensulfame, it is characterized in that, it comprises the steps:

[0031] Step 1: Sulfonation: Add 80g of hydroquinone and 70g of concentrated sulfuric acid into the same three-necked bottle respectively, then heat in a water bath, and slowly raise the temperature until the hydroquinone is completely melted into a liquid state, then stir the solution, after stirring , keep the three-necked bottle warm for 1 hour, after keeping warm for one hour, lower the temperature to 40°C, then add 160g of distilled water and 3.2g of activated carbon in turn to raise the temperature to 55°C, decolorize and stir for 30min, then filter to obtain 2,5-di Hydroxybenzenesulfonic acid solution;

[0032] Step 2: Salt formation: Pour the filtrate obtained in step 1 into another three-necked flask, cool the filtrate to 25°C, and then slowly add 2,5-dihydroxybenzenesulfonic acid to diethylamine in a mass ratio of 2 : the diethylamine of 1, after reaction finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com