Special modified graphene for polymerization of vinyl chloride

A technology of vinyl chloride polymerization and graphene, which is applied in the treatment of dyed low-molecular organic compounds, dyed high-molecular organic compounds, and fibrous fillers. Simple, Reinforced Resin Performance, Effect with Many Edge Defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

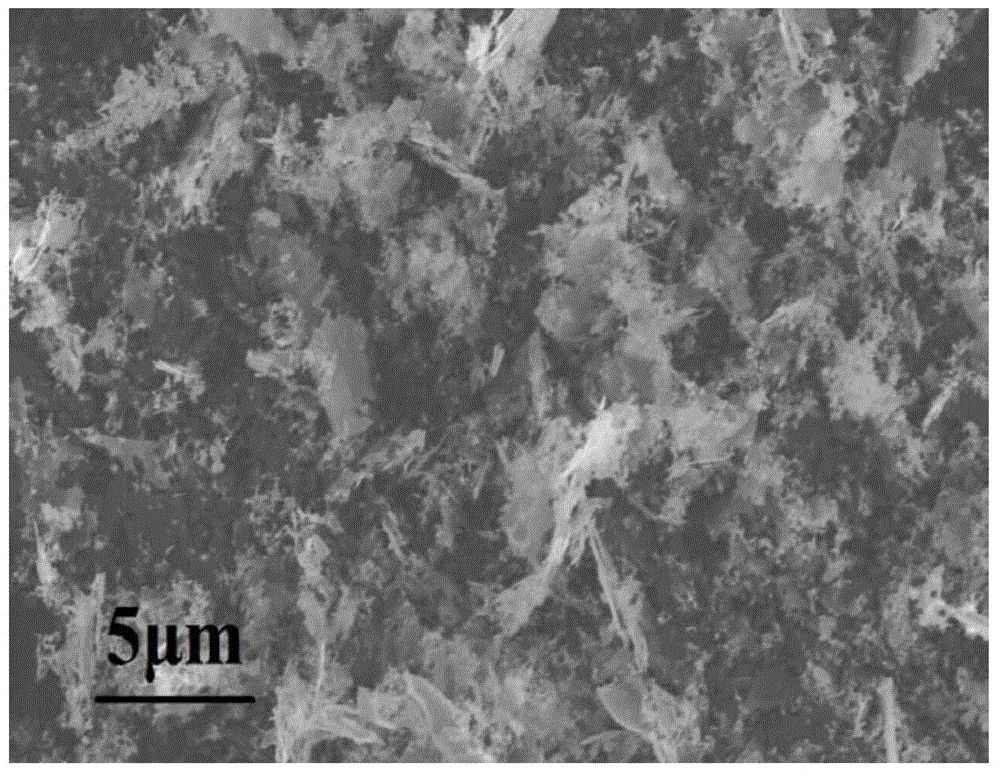

Image

Examples

Embodiment 1

[0030] (1) Weigh 30g of sodium hydroxide and 300g of water to make a sodium hydroxide solution, add 5g of earthy graphite, and bathe in water at 150°C for 2 hours; take out the mixed solution and filter, wash with water and suction filter until neutral, and obtain graphite slurry .

[0031] (2) Fully dissolve 0.15 g of sodium dodecylbenzene sulfonate and 0.1 g of hydroxypropyl methylcellulose in 600 g of water to form a composite modifier solution.

[0032] (3) Add the graphite slurry in step (1) to the composite modifier solution in step (2), and mix thoroughly to obtain a uniform graphite dispersion.

[0033] (4) Add the graphite dispersion in the step (3) to a nano-sand mill, grind fully, the rotating speed is 2500rpm, and the time is 5 hours to obtain a modified graphene slurry.

[0034] (5) Take out the modified graphene slurry and spray dry to obtain the modified graphene powder.

Embodiment 2

[0036] (1) Weigh 30g of sodium hydroxide and 300g of water to make a sodium hydroxide solution, add 5g of earthy graphite, and bathe in water at 150°C for 2 hours; take out the mixed solution and filter, wash with water and suction filter until neutral, and obtain graphite slurry .

[0037] (2) Fully dissolve 0.1g sodium dodecylbenzenesulfonate, 0.1g hydroxypropyl methylcellulose, and 0.05g sodium stearate in 600g water to form a compound modifier solution.

[0038] (3) Add the graphite slurry in step (1) to the composite modifier solution in step (2), and mix thoroughly to obtain a uniform graphite dispersion.

[0039] (4) Add the graphite dispersion in the step (3) to a nano-sand mill, grind fully, the rotating speed is 2500rpm, and the time is 5 hours to obtain a modified graphene slurry.

[0040] (5) Take out the modified graphene slurry and spray dry to obtain the modified graphene powder.

Embodiment 3

[0042] (1) Weigh 10g of potassium hydroxide and 200g of water to make a potassium hydroxide solution, add 4g of earthy graphite, and bathe in water at 150°C for 2 hours; take out the mixed solution and filter, wash with water and suction filter until neutral to obtain graphite slurry .

[0043] (2) Dissolve 0.1g of sodium dodecylbenzenesulfonate and 0.1g of hydroxypropyl methylcellulose in 400g of water to form a composite modifier solution.

[0044] (3) Add the graphite slurry in step (1) to the composite modifier solution in step (2), and mix thoroughly to obtain a uniform graphite dispersion.

[0045] (4) Add the graphite dispersion in the step (3) to a nano-sand mill, grind thoroughly, the rotating speed is 2000rpm, and the time is 8 hours to obtain a modified graphene slurry.

[0046] (5) Take out the modified graphene slurry and spray dry to obtain the modified graphene powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com