Plant oil-based polyurethane composite material and preparation method thereof

A technology of vegetable oil-based and composite materials, which is applied in the field of vegetable oil-based polyurethane composite materials and its preparation, can solve the problems of poor mechanical properties, thermal properties and weather resistance of polyurethane, and achieve the effects of excellent mechanical properties, lower production costs, and improved dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

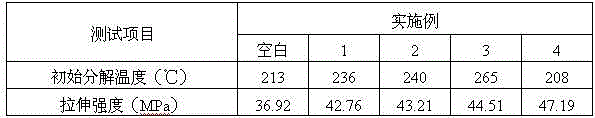

Examples

preparation example Construction

[0023] A method for synthesizing an environmentally friendly polyurethane composite material with excellent mechanical properties and thermal stability. The vegetable oil-based polyurethane composite material comprises the following components:

[0024] (a) Vegetable oil-based polyols;

[0025] (b) Organotin catalysts, used in an amount of 1% to 10% of the mass of vegetable oil-based polyols;

[0026] (c) Polyisocyanate, the dosage is 0.8 to 1.0 times the mass of vegetable oil-based polyol;

[0027] (d) Short-chain chain extender, the dosage is according to the chain extension ratio n OH : n NCO =1︰1~1︰1.5 added, that is to control the molar ratio of hydroxyl group and isocyanate in the material to 1︰1~1︰1.5;

[0028] (f) The nano-reinforcement material is fluorine-containing polysilsesquioxane (POSS), calculated by weight percentage, which is 0.1% to 1.2% of the total mass of the component;

[0029] Specifically, the above-mentioned vegetable oil-based polyol is used a...

Embodiment 1

[0043] A vegetable oil-based polyurethane composite material, comprising the following components:

[0044] Soybean oil-based polyol (hydroxyl value: 155mg KOH / g) 2 g;

[0045] Stannous octoate: 0.20 g, 10% of the mass of vegetable oil-based polyol;

[0046] Isophorone diisocyanate (IPDI) 1.90g, 0.95 times the mass of vegetable oil polyol;

[0047] 1,4-butanediol 0.30 g, chain extension ratio n OH : n NCO =1︰1.27;

[0048] Fluorinated polysilsesquioxane (POSS) 0.0060 g, 0.14% by weight;

[0049] Solvent tetrahydrofuran 10 mL, solid content 33%;

[0050] The preparation method of this polyurethane composite material is as follows:

[0051] 1. According to the formula, weigh each component, including vegetable oil-based polyol, organotin catalyst, solvent, nano-enhanced material fluorine-containing polysilsesquioxane (POSS) and polyisocyanate, N 2 React at 80°C for 2 h under protection to synthesize polyurethane prepolymer;

[0052] 2. Add the required mass of chain e...

Embodiment 2

[0054] A vegetable oil-based polyurethane composite material, comprising the following components:

[0055] Soybean oil-based polyol (hydroxyl value: 155mg KOH / g) 2 g;

[0056] Stannous octoate 0.20 g, 10% of the mass of vegetable oil-based polyol;

[0057] Isophorone diisocyanate (IPDI) 1.90g, 0.95 times the mass of vegetable oil polyol;

[0058] 1,4-butanediol 0.30 g, chain extension ratio n OH : n NCO =1︰1.27;

[0059] Fluorinated polysilsesquioxane (POSS) 0.0240 g, 0.54% by weight;

[0060] Solvent tetrahydrofuran 10 mL, solid content 33%;

[0061] The preparation method of the polyurethane composite material is as described in Example 1, and will not be repeated here to save space.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com