Special low-VOC scraping-resisting polypropylene composite material for automotive trim and preparation method of composite material

A technology for automotive interiors and composite materials, which is applied in the field of ultra-low shrinkage, low VOC and scratch-resistant polypropylene composite materials for automotive interiors and its preparation. Crystallization properties, reduce shrinkage, meet the effect of ultra-low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

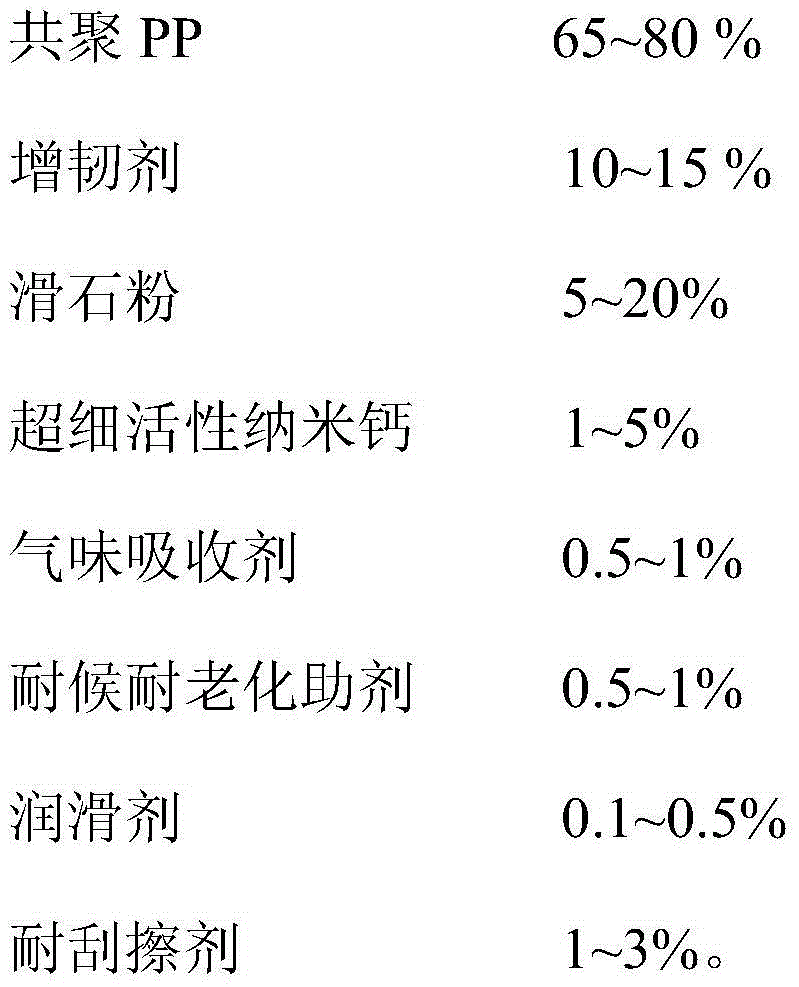

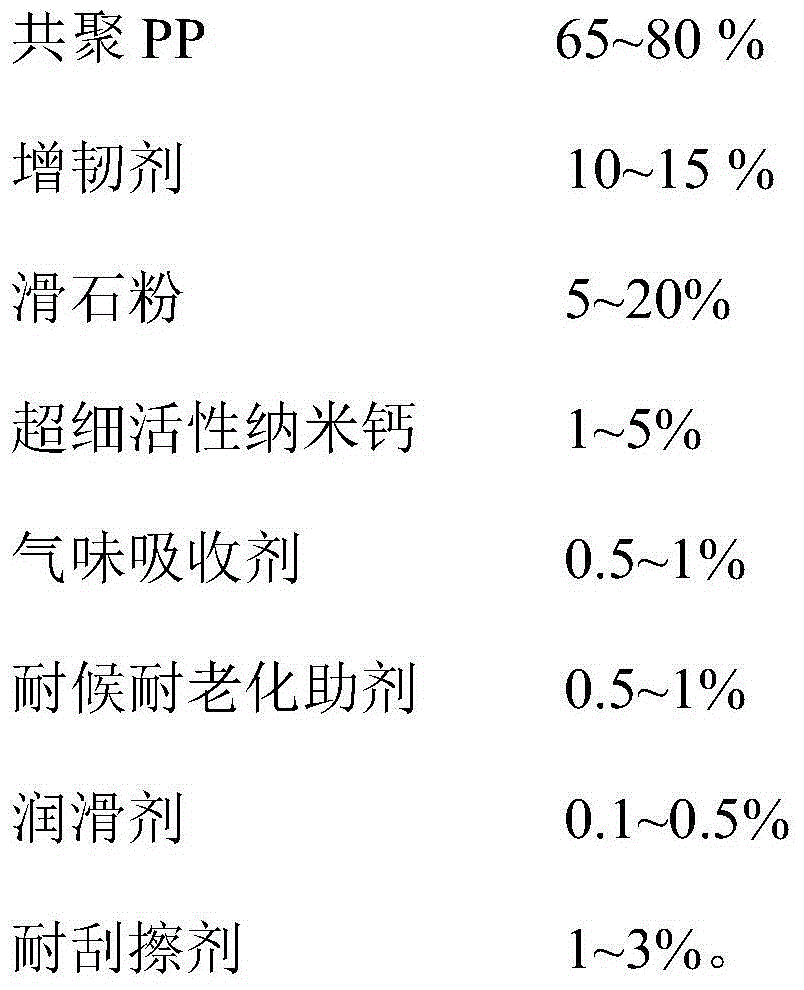

[0020] An ultra-low shrinkage, low VOC, and scratch-resistant polypropylene composite material for automotive interiors, comprising the following components by weight percentage: 80% copolymerized PP; 11% toughening agent; 5.9% talcum powder; 1% ultrafine active nano-calcium; odor 0.5% absorbent; 0.5% weather-resistant and aging-resistant additive; 0.1% lubricant; 1% scratch-resistant agent.

[0021] The copolymerized PP is low-VOC polypropylene with a melt index MI of 10-50g / 10min, preferably Maoming Petrochemical Company PP MML28S; the toughening agent is ethylene, propylene or octene copolymer, preferably ExxonMobil POE; The preferred odor absorber zinc castor alcohol of Degussa Company; the weather resistance aid is one or both of hindered amines, ultraviolet absorbers, free radical scavengers, preferably BASF 1010, BASF 168; The anti-aging additive is hindered phenols or phosphite, preferably V680; the lubricant is oxidized polyhexene wax or calcium stearate, preferably H...

Embodiment 2

[0028] An ultra-low shrinkage, low VOC, and scratch-resistant polypropylene composite material for automotive interiors, comprising the following components by weight percentage: 69% of copolymerized PP; 15% of toughening agent; 10% of talcum powder; 1.5% of ultrafine active nano-calcium; 1% odor absorber; 1% weather and aging resistance additive; 0.5% lubricant; 2% scratch resistance agent.

[0029] The copolymerized PP is low-VOC polypropylene with a melt index MI of 10-50g / 10min, preferably Maoming Petrochemical Company PP MML28S; the toughening agent is ethylene, propylene or octene copolymer, preferably ExxonMobil POE; The preferred odor absorber zinc castor alcohol of Degussa Company; the weather resistance aid is one or both of hindered amines, ultraviolet absorbers, free radical scavengers, preferably BASF 1010, BASF 168; The anti-aging additive is hindered phenols or phosphite, preferably V680; the lubricant is oxidized polyhexene wax or calcium stearate, preferably H...

Embodiment 3

[0036] An ultra-low shrinkage, low VOC, and scratch-resistant polypropylene composite material for automotive interiors, comprising the following components by weight percentage: 65% copolymerized PP; 10% toughening agent; 19% talcum powder; 1% ultrafine active nano-calcium; odor 1% absorbent; 0.75% weather and aging resistance additive; 0.25% lubricant; 3% anti-scratch agent.

[0037]The copolymerized PP is low-VOC polypropylene with a melt index MI of 10-50g / 10min, preferably Maoming Petrochemical Company PP MML28S; the toughening agent is ethylene, propylene or octene copolymer, preferably ExxonMobil POE; The preferred odor absorber zinc castor alcohol of Degussa Company; the weather resistance aid is one or both of hindered amines, ultraviolet absorbers, free radical scavengers, preferably BASF 1010, BASF 168; The anti-aging additive is hindered phenols or phosphite, preferably V680; the lubricant is oxidized polyhexene wax or calcium stearate, preferably Honeywell's polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com