Visible light super-transmissible coating material for Low-E glass and preparation method thereof

A coating material and visible light technology, applied in coatings, alkali metal silicate coatings, etc., can solve problems such as inability to meet architectural diversification, lighting decline, and difficulty in realizing coating diversification functions, and achieve processing equipment and operation Simple, functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

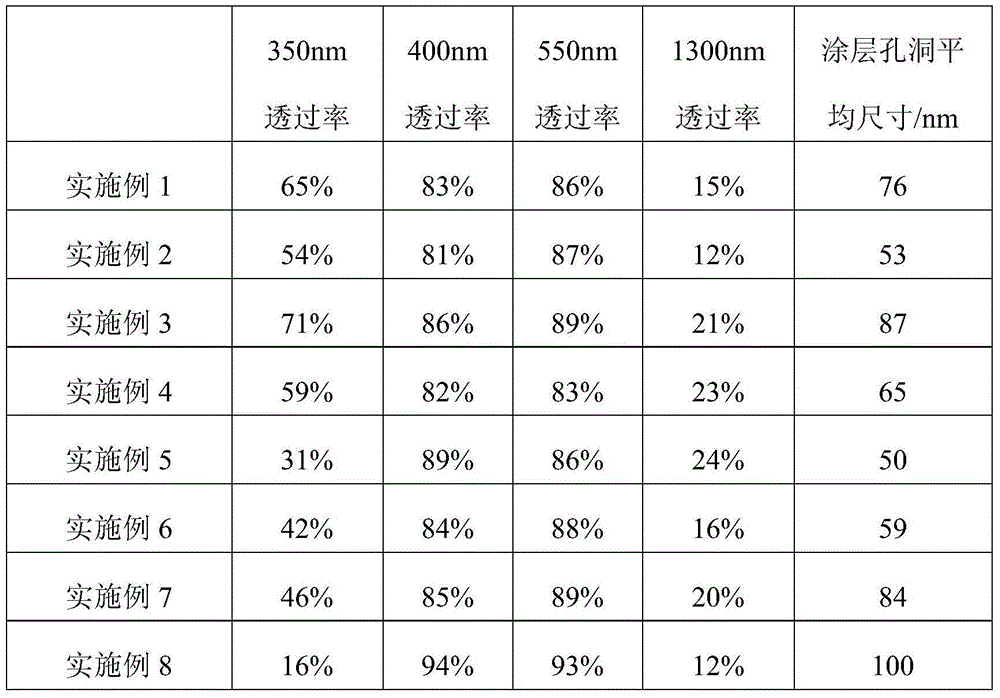

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of hydrophilic coating 1

[0026] The solution system ratio is: polyacrylic acid (number average molecular weight: 20000) 0.5wt.%, adjust the pH value to 9-10; sodium silicate 1.0wt.%, the solvent is deionized water, and the hybrid solution 1 is prepared.

[0027] Glass surface pretreatment: Cut 6mm thick float glass into a size of 50mm×50mm. The cut glass is surface treated through the following steps: washing with deionized water, washing with 95wt.% ethanol, washing with concentrated sulfuric acid to remove organic matter, washing with deionized water three times, and drying in vacuum for 24 hours.

[0028] Film coating-film formation-inorganic curing of the film: drop 0.2-0.5g of the hybrid solution on the pretreated glass surface, and spin the film at a speed of 1000-2000rpm. The glass coated with the hybrid solution was naturally volatilized in a dust-free clean container until dried, and then dried under vacuum for 24-36 hours. After d...

Embodiment 2

[0029] Embodiment 2: Preparation of hydrophilic coating 2

[0030] The ratio of the solution system is: acrylic acid-acrylamide copolymer (number average molecular weight 50000) 1.5wt.%, adjust the pH value to 9-10; water-soluble silicone oil 1.0wt.%, the solvent is deionized water, prepared as a hybrid Solution 2.

[0031] Glass surface pretreatment: with embodiment 1.

[0032]Film coating-film formation-inorganic curing of the film: drop 0.2-0.5g of the hybrid solution on the pretreated glass surface, and spin the film at a speed of 1000-2000rpm. Spray dilute hydrochloric acid with a concentration of 2-5wt.% on the surface of the glass coated with the hybrid solution, and the spraying amount is 0.1-0.2g, and then continue to spread evenly at a speed of 1000-2000rpm. The glass coated with the hybrid solution and dilute hydrochloric acid was naturally volatilized in a dust-free clean container until it dried, and after standing for 12 hours, the surface was cleaned with deio...

Embodiment 3

[0033] Embodiment 3: Preparation of hydrophilic coating 3

[0034] The ratio of the solution system is: sodium polyacrylate (number average molecular weight: 80,000) 1.5wt.%, adjust the pH value to 9-10; sodium silicate 2.0wt.%, solvent is deionized water, and the hybrid solution 3 is prepared.

[0035] Glass surface pretreatment: with embodiment 1.

[0036] Film coating-film formation-inorganic curing of the film: drop 0.2-0.5g of the hybrid solution on the pretreated glass surface, and spin the film at a speed of 1000-2000rpm. Spray dilute hydrochloric acid with a concentration of 2-5wt.% on the surface of the glass coated with the hybrid solution, and the spraying amount is 0.1-0.2g, and then continue to spread evenly at a speed of 1000-2000rpm. The glass coated with the hybrid solution and dilute hydrochloric acid was naturally volatilized in a dust-free clean container until it dried, and after standing for 12 hours, the surface was cleaned with deionized water for 5 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com