Single-component primer-topcoat paint commonly used on stainless steel, galvanized sheet and aluminum alloy and preparation method of single-component primer-topcoat paint commonly used on stainless steel, galvanized sheet and aluminum alloy

A technology of galvanized sheet and aluminum alloy, which is applied in the direction of coating, etc., can solve the problems of increased difficulty and achieve the effect of convenient construction, stable performance and large demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

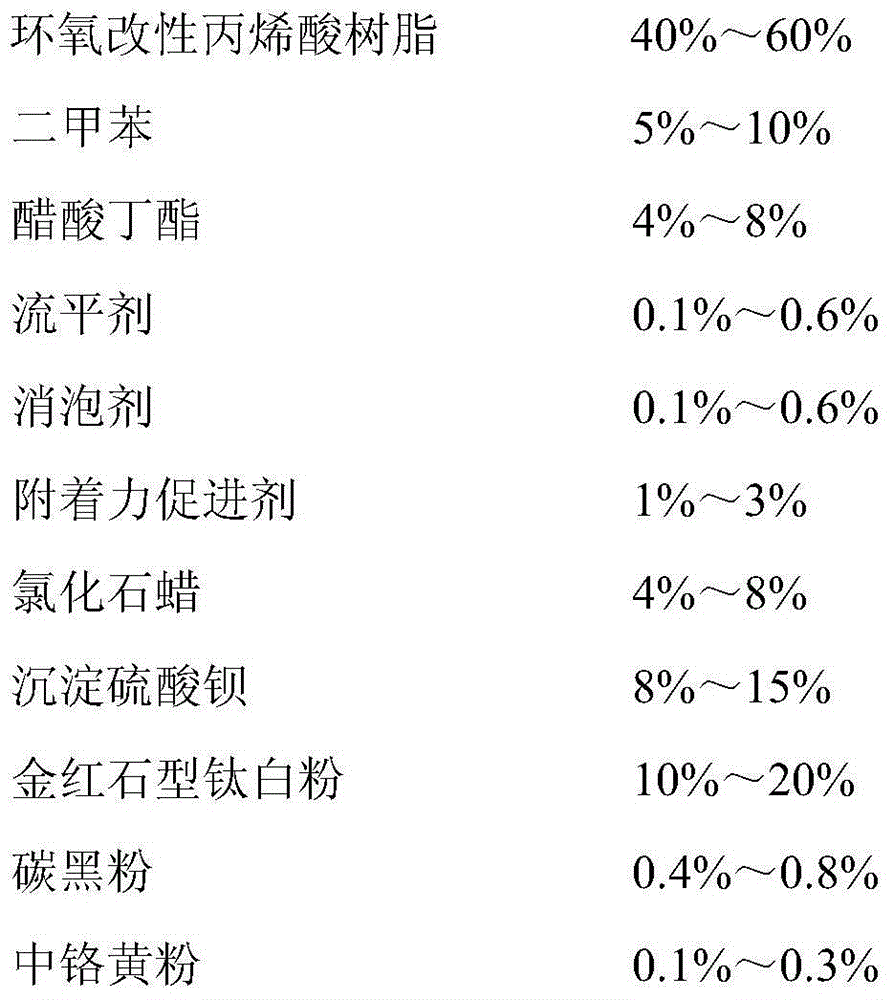

[0040] A general-purpose single-component bottom-surface-in-one coating on stainless steel, galvanized sheet, and aluminum alloy, which consists of the following components in weight percentage:

[0041]

[0042] The preparation process is as follows:

[0043] (1) In proportion, 1005 resin with 50% formula quantity is added in the container;

[0044] (2) Add xylene and stir slowly at 500-600r / min;

[0045] (3) Add 80% alkyd butyl ester, stir at 500-600r / min;

[0046] (4) Add leveling agent, defoamer, and chlorinated paraffin in sequence according to the formula amount, and disperse and stir at 600-800r / min;

[0047] (5) Add rutile titanium dioxide, precipitated barium sulfate, carbon black powder, and medium chrome yellow powder in sequence, stir evenly at 600-800r / min, disperse at a high speed of 1200r / min for 30min, and then grind until the fineness is less than 25μm;

[0048] (6) Add the adhesion promoter, the remaining 1005 resin and polyamide wax, and disperse at a ...

Embodiment 2

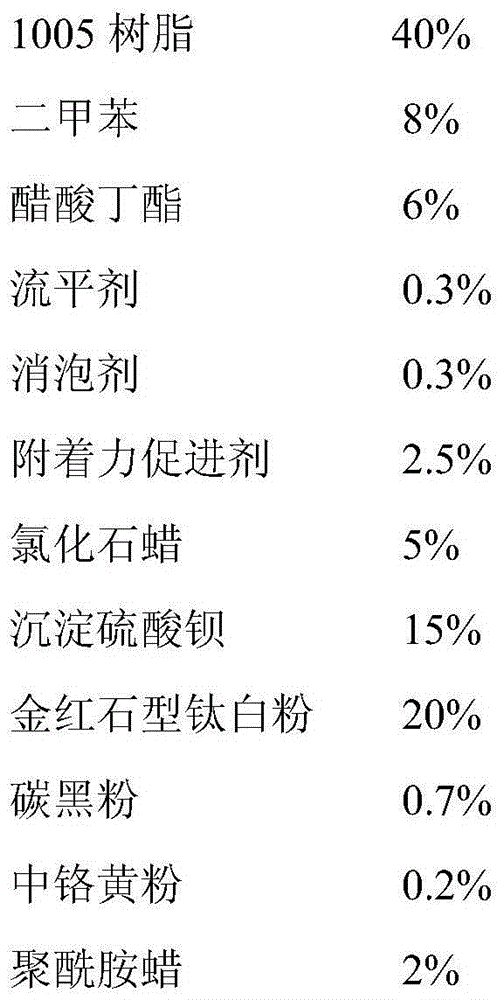

[0052] A general-purpose single-component bottom-surface-in-one coating on stainless steel, galvanized sheet, and aluminum alloy, which consists of the following components in weight percentage:

[0053]

[0054] Preparation Process

[0055] (1) In proportion, 1005 resin with formula quantity 60% is added in the container;

[0056] (2) Add xylene and stir slowly at 500-600r / min;

[0057] (3) Add 75% alkyd butyl ester, stir at 500-600r / min;

[0058] (4) Add leveling agent, defoamer, and chlorinated paraffin in sequence according to the formula amount, and disperse and stir at 600-800r / min;

[0059] (5) Add rutile titanium dioxide, precipitated barium sulfate, carbon black powder, and medium chrome yellow powder in sequence, stir evenly at 600-800r / min, disperse at a high speed of 1200r / min for 30min, and then grind until the fineness is less than 25μm;

[0060] (6) Add the adhesion promoter, the remaining 1005 resin and polyamide wax, and disperse at a high speed of 1100r...

Embodiment 3

[0064] A general-purpose single-component bottom-surface-in-one coating on stainless steel, galvanized sheet, and aluminum alloy, which consists of the following components in weight percentage:

[0065]

[0066] The preparation process is as follows:

[0067] (1) Proportionally, add 1005 resin with formula quantity 40% in the container;

[0068] (2) Add xylene and stir slowly at 500-600r / min;

[0069] (3) Add alkyd butyl ester with formula quantity 85%, stir evenly at 500~600r / min;

[0070] (4) Add leveling agent, defoamer, and chlorinated paraffin in sequence according to the formula amount, and disperse and stir at 600-800r / min;

[0071] (5) Add rutile titanium dioxide, precipitated barium sulfate, carbon black powder, and medium chrome yellow powder in sequence, stir evenly at 600-800r / min, disperse at a high speed of 1200r / min for 30min, and then grind until the fineness is less than 25μm;

[0072] (6) Add the adhesion promoter, the remaining 1005 resin and polyamid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com