Solvent-free epoxy coating for steel pipe pile

An epoxy coating, solvent-free technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as ineffective protection of steel, and achieve good film-forming properties, excellent seawater resistance, and stable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

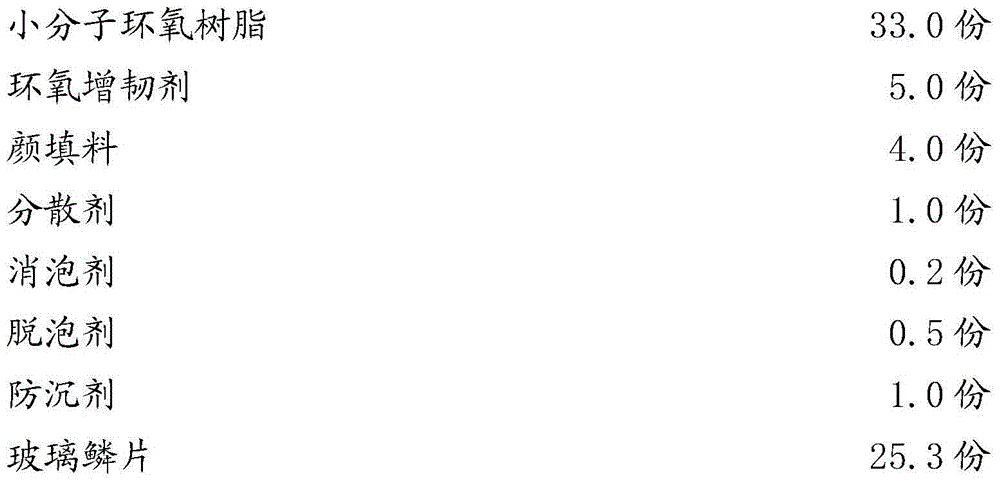

Embodiment 1

[0016] The unit is parts by mass

[0017] Main ingredient:

[0018]

[0019]

[0020] Hardener:

[0021] Modified amine 96.0 parts

[0022] 4.0 parts of curing accelerator

[0023] Prepare the main agent and curing agent according to the mass ratio of 10:3. The specific preparation method is: add the components in the main agent except the anti-settling agent into the reaction kettle for high-speed stirring, and disperse them into a slurry, and then use After the grinder grinds to 50 microns, add anti-sedimentation agent and stir evenly at low speed; then add modified amine and curing accelerator to the main ingredient and stir evenly before discharging.

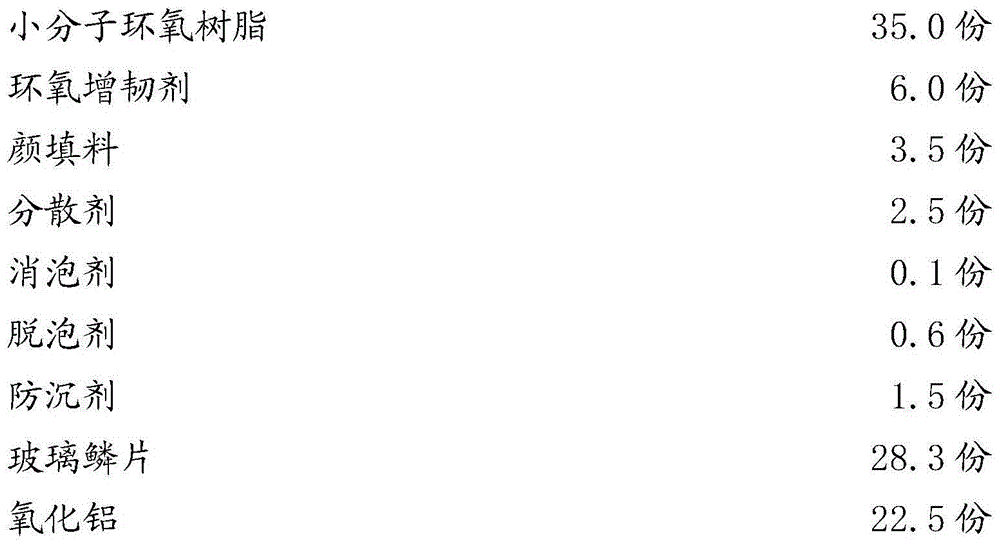

Embodiment 2

[0025] The unit is parts by mass

[0026] Main agent:

[0027]

[0028] Hardener:

[0029] Modified amine 97.0 parts

[0030] 3.0 parts of curing accelerator

[0031] Prepare the main agent and curing agent according to the mass ratio of 10:3. The specific preparation method is: add the components in the main agent except the anti-settling agent into the reaction kettle for high-speed stirring, and disperse them into a slurry, and then use After the grinder grinds to 50 microns, add anti-sedimentation agent and stir evenly at low speed; then add modified amine and curing accelerator to the main ingredient and stir evenly before discharging.

[0032] Described low-molecular-weight epoxy resin is the multi-epoxy-based low-molecular-weight epoxy resin produced by Mitsui of Japan or HEXION of the United States, 828 and 128 produced by Nanya Resin, and domestic brand E-51 epoxy resin.

[0033] The modified amine is a diethylenetriamine-modified amine curing agent produced by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com