Probiotic corn leavening agent capable of increasing content of L-lactic acid and application of probiotic corn leavening agent

A starter and probiotic technology, applied in application, fermentation, and growth stimulation by adding compounds, can solve the problems of limited utilization of complex carbohydrates, low energy utilization rate of corn, and low activity of amylase, so as to improve the palatability of feed Sexuality, increasing L-lactic acid content, the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Adjust the mixing ratio of corn and water, and control the moisture content of the material to 25%; the control group only adds water; the test group 1 is inoculated with citric acid at a mass ratio of 1% on the basis of the control group; the test group 2 is inoculated with the control group. Basically, the probiotic corn starter of the present invention is inoculated at a mass ratio of 0.1%. 3 repetitions per set.

[0025] After the materials are mixed evenly, they are placed in a double-layer sealed bag and fermented anaerobically at 37°C for 72 hours. Use the PHS-3C pH meter to measure the pH. Weigh 10 g of fermentation sample, add 90 ml of water, stir magnetically at room temperature for 1 h, centrifuge at 10,000 rpm for 10 min, take the supernatant, and use SBA-40D biosensor analyzer to measure the content of L-lactic acid. Using MRS medium, use the pouring method, culture at 37°C for 48 hours, and measure the amount of lactic acid bacteria; use PDA medium, adop...

Embodiment 2

[0034] Adjust the mixing ratio of corn and water, and control the moisture content of the material to 25%. Both the control group and the test group use the corn starter formula, but the amount of Lactobacillus germanus added is different. The control group did not contain Lactobacillus germanus, and the test group-1 added 1*10 6 CFU / g Lactobacillus germanus, test group-2 added 5*10 6 CFU / g Lactobacillus germanus, test group-3 added 1*10 7 CFU / g Lactobacillus germanus. With a mass ratio of 0.1%, according to the formula of the control group and the series of test groups, the probiotic corn starter of the present invention was inoculated to investigate the effect of the core component of Lactobacillus germanus on the L-lactic acid content of corn after fermentation. 3 repetitions per set. After the materials are mixed evenly, they are placed in a double-layer sealed bag and fermented anaerobically at 37°C for 72 hours. Weigh 10 g of fermentation sample, add 90 ml of water, ...

Embodiment 3

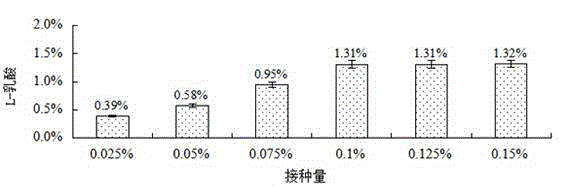

[0039] Adjust the mixing ratio of corn and water, control the moisture content of the material to be 25%; adopt gradient inoculation amount (mass ratio): 0.025%, 0.05%, 0.075%, 0.1%, 0.125%, 0.15%, inoculate the probiotics of the present invention Corn starter, to investigate the effect of inoculation amount on L-lactic acid content after corn fermentation. 3 repetitions per set. After the materials are mixed evenly, they are placed in a double-layer sealed bag and fermented anaerobically at 37°C for 72 hours. Weigh 10 g of fermentation sample, add 90 ml of water, stir magnetically at room temperature for 1 h, centrifuge at 10,000 rpm for 10 min, take the supernatant, and use SBA-40D biosensor analyzer to measure the content of L-lactic acid.

[0040] figure 1 Indicates the content of L-lactic acid after corn fermentation under different inoculum amounts. When the inoculum ratio was lower than 0.1%, the L-lactic acid content of fermented corn increased with the continuous i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com