Preparation method and product of paenibacillus chymosin

A technology of Paenibacillus and Bacillus, applied in the direction of microorganism-based methods, biochemical equipment and methods, hydrolytic enzymes, etc., can solve the problems that chymosin has not yet been obtained, achieve high specific activity, simplify preparation process steps, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

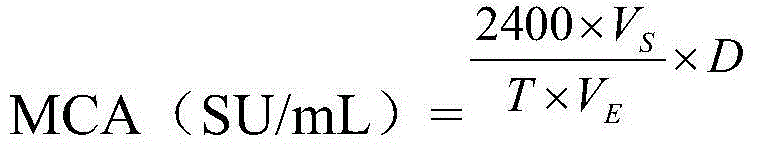

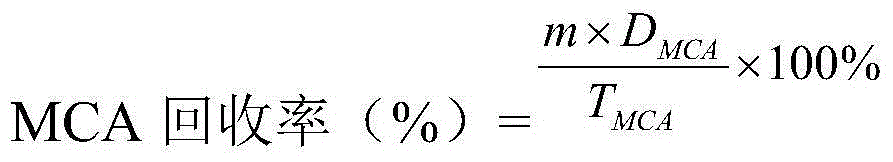

[0027] The extraction method of chymosin in the Paenibacillus fermented liquid of embodiment 1

[0028] The bacterial strain Paenibacillus BD3526 described in the present invention has been preserved in the General Microorganism Center (CGMCC) of China Committee for the Collection of Microorganisms on October 14, 2013. The taxonomic name of the strain is Paenibacillus sp., and the preservation number of the strain is: CGMCC No.8333. For details, please refer to the Chinese patent application (CN 103740618A).

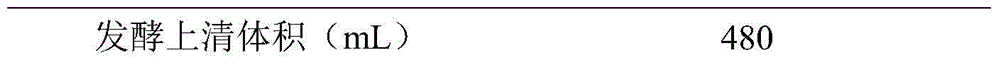

[0029] Paenibacillus BD3526CGMCC No.8333 was fermented and cultivated using bran medium. The composition of the bran medium was: the mass percentage of wheat bran was 2%, the balance was water, the sample volume was 30mL, and the temperature was 30°C. The shaking speed of the bed was 300rpm. After 48 hours of fermentation and cultivation time, the BD3526 fermentation broth was collected; the supernatant fermentation broth was collected after centrifugation at 4°C, 15000g...

Embodiment 2

[0055] The extraction method of chymosin in the Paenibacillus fermented liquid of embodiment 2

[0056] Paenibacillus BD3526 CGMCC No.8333 was fermented and cultivated using bran medium. The composition of the bran medium was: the mass percentage of wheat bran was 5%, the balance was water, the sample volume was 30mL, and the temperature was 30°C. The shaking speed of the shaker was 300rpm. After 48 hours of fermentation and cultivation, the BD3526 fermentation broth was collected; the supernatant fermentation broth was collected after centrifugation at 4°C, 15000g, 20min, and a small amount of the supernatant fermentation broth was diluted 5 times with PBS, and Measure the enzyme activity (SU / mg) and protein content (mg / mL) of the fermentation supernatant; mix 95% ethanol with the supernatant fermentation broth at a volume ratio of 4:1 (V / V), mix well and then store at 4°C Let stand for 5h.

[0057] Centrifuge at 15,000g at 4°C for 15min to collect alcohol-precipitated subst...

Embodiment 3

[0061] The extraction method of chymosin in the Paenibacillus fermented liquid of embodiment 3

[0062] Paenibacillus BD3526CGMCC No.8333 was fermented and cultivated using bran medium. The composition of the bran medium was: the mass percentage of wheat bran was 3%, the balance was water, the sample volume was 30mL, the temperature was 30°C, and the The shaking speed of the bed was 300rpm. After 48 hours of fermentation and cultivation time, the BD3526 fermentation broth was collected; the supernatant fermentation broth was collected after centrifugation at 4°C, 15000g, 20min, and a small amount of the supernatant fermentation broth was diluted 5 times with PBS, and measured Enzyme activity (SU / mg) and protein content (mg / mL) of the fermentation supernatant; mix 95% ethanol with the supernatant fermentation broth at a volume ratio of 4:1 (V / V), mix well and then statically place at 4°C set for 1h.

[0063] Centrifuge at 15,000g at 4°C for 15min to collect alcohol-precipitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com