A kind of method that enzymatic method prepares sodium gluconate

A sodium gluconate, enzymatic preparation technology, applied in the field of enzymatic preparation of sodium gluconate, can solve the problems of troublesome extraction and refining, affecting product quality and conversion rate, etc., and achieve less impurities, high equipment utilization rate, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

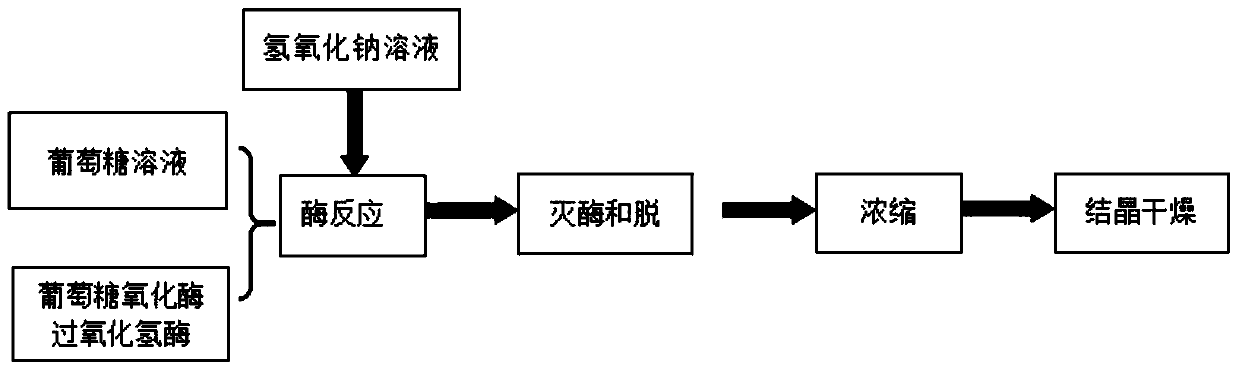

Method used

Image

Examples

Embodiment 1

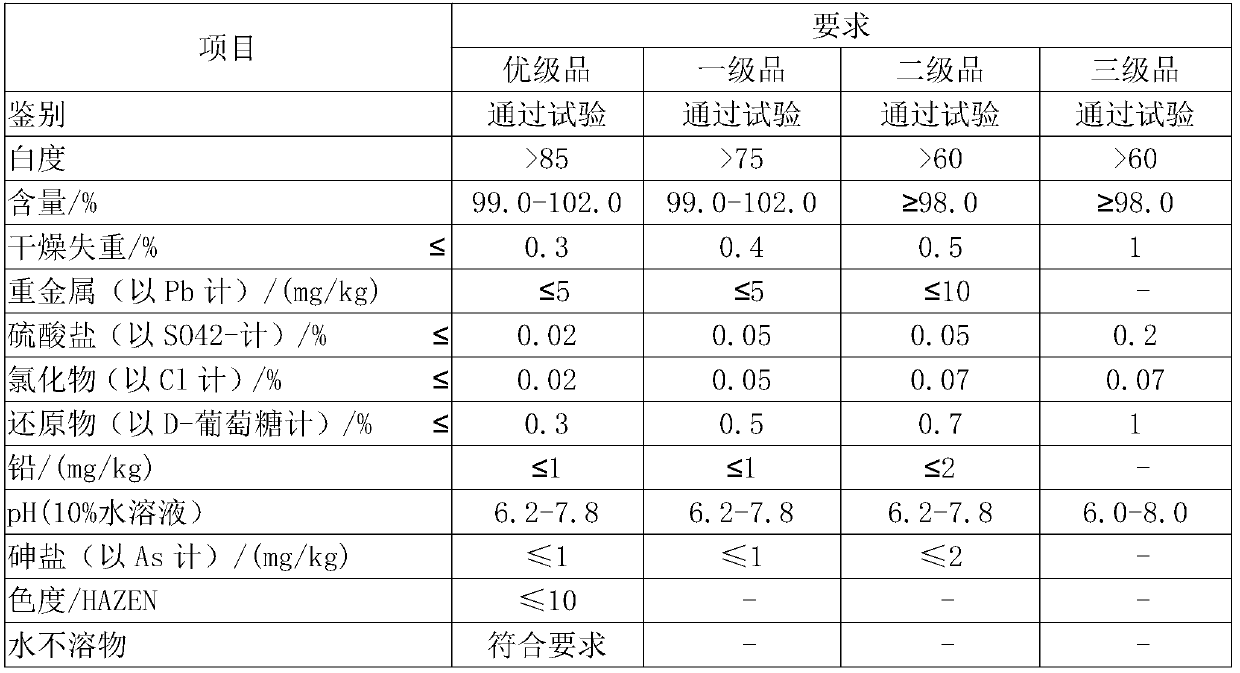

[0018] Add 20L of 40% glucose solution to a 30L tank, at the same time add 150mL (to 6000U / ml) glucose oxidase, 75 (to 100,000 U / ml) mL catalase, set the reaction pH to 6.0, and 50% Sodium hydroxide was added to adjust the pH, the reaction temperature was maintained at 38°C, the compressed air was introduced, the ventilation rate was 0.5vvm, the tank pressure was maintained at 0.2MPa, the stirring was turned on, and the speed was 250-300r / min. Reaction for about 24 hours, the residual sugar is measured <0.3%, add 50% sodium hydroxide to 3.56L, and adjust the reaction pH to 7.0, maintain for half an hour, and the catalytic reaction ends. After the reaction is over, add 600g activated carbon and heat to boiling for 5 minutes, micropore suction filtration to obtain a colorless solution, the solution obtained by suction filtration is concentrated under reduced pressure at minus 0.08MPa and temperature 80°C to a concentration greater than 70%, and the solution Fluidized bed crystall...

Embodiment 2

[0020] Add 20L of 35% glucose solution in a 30L tank, add 200mL (to 8000U / ml) glucose oxidase and 60mL (to 100,000 U / ml) catalase at the same time, set the reaction pH to 6.5, and use 50% hydrogen Sodium oxide flow is added to adjust the pH. The reaction temperature was maintained at 38°C, compressed air was introduced, the ventilation rate was 0.8vvm, the tank pressure was maintained at 0.2MPa, the stirring was turned on, and the speed was 250-300r / min. Reaction time 20 hours, measured residual sugar <0.3%, when 50% sodium hydroxide is added to reach 3.11L, the pH of the reaction is adjusted to 7.0, and the catalytic reaction ends. After the reaction is over, add 600g activated carbon and heat to boiling for 5 minutes, micropore suction filtration to obtain a colorless solution, the solution obtained by suction filtration is concentrated under reduced pressure at minus 0.08MPa and temperature 80°C to a concentration greater than 70%, and the solution Fluidized bed crystalliza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com