Arc ion plating device for coating of inner wall of long pipe

A technology of arc ion plating and arc striking device, which is applied in ion implantation plating, sputtering plating, vacuum evaporation plating, etc., can solve corrosion, wear and high temperature oxidation, cannot meet the requirements of inner surface modification and strengthening, Problems such as limited depth of film deposition to achieve the effect of ensuring uniformity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

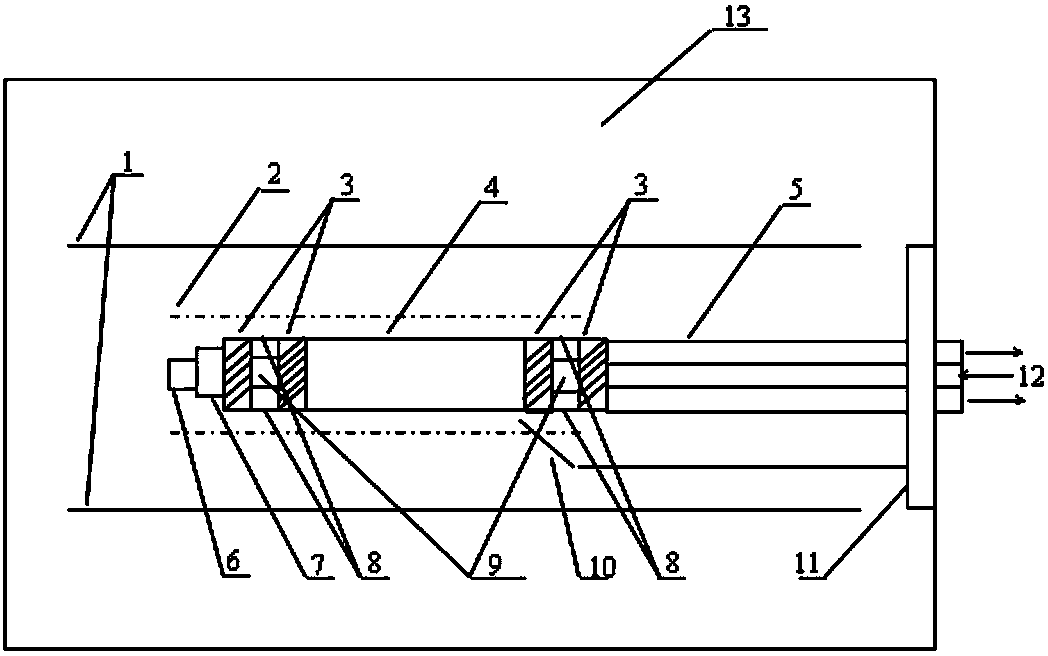

[0019] Example 1: Depositing a metal titanium film layer on the inner surface of a stainless steel tube with a wall thickness of 1 mm in diameter and a length of Φ80×600 mm

[0020] Using a cylindrical target arc source with an outer diameter of 26mm, the hollow cylindrical cathode target is pure Ti, and a stainless steel tube with a wall thickness of 1mm and a diameter of Φ80×600mm is selected. Put it into the sample holder, the center line of the stainless steel tube coincides with the axis of the target arc source, and the moving speed of the sample holder is 2mm longitudinally and rotates one circle per minute. The vacuum chamber is evacuated to 6.7×10 -3 After Pa, Ar gas was introduced and the gas pressure in the vacuum chamber was maintained at 0.6Pa. First, the arc is ignited, the arc current is 60A, and the arc voltage is 20V. After the normal arc discharge, the sample holder starts to move, and the negative bias voltage of 900V is applied for bombardment cleaning for...

Embodiment 2

[0021] Example 2: Depositing a titanium nitride film layer on the inner surface of a stainless steel tube with a wall thickness of 1 mm in diameter and a length of Φ60×600 mm

[0022] Using a cylindrical target arc source with an outer diameter of 26mm, the hollow cylindrical cathode target is pure Ti, and a stainless steel tube with a wall thickness of 1mm and a diameter of Φ60×600mm is selected. Put it into the sample holder, the center line of the stainless steel tube coincides with the axis of the target arc source, and the moving speed of the sample holder is 2mm longitudinally and rotates one circle per minute. The vacuum chamber is evacuated to 6.7×10 -3 After Pa, Ar gas was introduced and the gas pressure in the vacuum chamber was maintained at 0.6Pa. First, the arc is ignited, the arc current is 60A, and the arc voltage is 20V. After the normal arc discharge, the sample holder starts to move, and the negative bias voltage of 900V is applied for bombardment cleaning f...

Embodiment 3

[0023] Example 3: A titanium nitride film was deposited on the inner surface of a stainless steel tube with a wall thickness of 1 mm in diameter and a length of Φ50×600 mm.

[0024] Using a cylindrical target arc source with an outer diameter of 26mm, the hollow cylindrical cathode target is pure Ti, and a stainless steel tube with a wall thickness of 1mm and a diameter of Φ50×600mm is selected. Put it into the sample holder, the center line of the stainless steel tube coincides with the axis of the target arc source, and the moving speed of the sample holder is 2mm longitudinally and rotates one circle per minute. The vacuum chamber is evacuated to 6.7×10-3 After Pa, Ar gas was introduced and the gas pressure in the vacuum chamber was maintained at 0.6Pa. First, the arc is ignited, the arc current is 60A, and the arc voltage is 20V. After the normal arc discharge, the sample holder starts to move, and the negative bias voltage of 900V is applied for bombardment cleaning for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com