A method for preparing high-quality znmgbeo thin films

A high-quality, thin-film technology, applied in chemical instruments and methods, from chemically reactive gases, crystal growth, etc., can solve problems such as large lattice, distortion, etc., achieve high luminous performance, ensure quality, and suppress the effect of defect luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] After cleaning the c-plane sapphire substrate, put it into the molecular beam epitaxy equipment, heat the substrate temperature to 600 °C, and adjust the growth chamber pressure to 2×10 -6 Torr, in radio frequency activated pure O 2 (purity 99.9999%) as O source, activated O 2 The radio frequency power is 350 W; metal Zn (purity 99.9998 %) source, Mg (purity 99.9999 %) source, Be (purity 99.9999 %) source are reaction sources, adjust the heating temperature of Zn source to 280 ℃, Mg source heating temperature to 350 ℃, Be source heating temperature to 880 ℃, grow ZnMgBeO film on c-plane sapphire, growth time is 3 hours, film thickness is about 350 nm.

[0016] Using the same process, ZnMgO thin film was grown on the substrate with metal Zn (purity 99.9998 %) source and Mg (purity 99.9999 %) source as the reaction source.

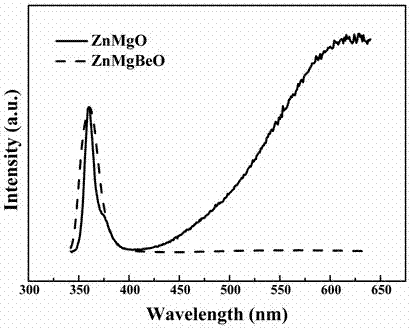

[0017] figure 1 The room temperature photoluminescence spectra of the ZnMgBeO thin film and the ZnMgO thin film are shown. It can be seen from th...

Embodiment 2

[0020] After cleaning the c-plane sapphire substrate, put it into the molecular beam epitaxy equipment, heat the substrate temperature to 700 °C, and adjust the growth chamber pressure to 3×10 -6 Torr, in radio frequency activated pure O 2 (purity 99.9999%) as O source, activated O 2 The radio frequency power is 350 W; metal Zn (purity 99.9998 %) source, Mg (purity 99.9999 %) source, Be (purity 99.9999 %) source are reaction sources, and the heating temperature of Zn source is adjusted to 280 ℃, and the heating temperature of Mg source is 350 ℃ 1. The Be source was heated to 900 °C, and a ZnMgBeO film was grown on the c-plane sapphire substrate. The growth time was 2 hours, and the film thickness was about 200 nm.

[0021] The prepared ZnMgBeO film has no defect peaks and has good optical properties; the background electron concentration is as low as 2×10 16 cm -3 .

Embodiment 3

[0023] After cleaning the ZnO single crystal substrate, put it into the molecular beam epitaxy equipment, heat the substrate temperature to 500 °C, and adjust the growth chamber pressure to 6×10 -6 Torr, in radio frequency activated pure O 2 (purity 99.9999%) as O source, activated O 2 The radio frequency power is 350 W; metal Zn (purity 99.9998 %) source, Mg (purity 99.9999 %) source, Be (purity 99.9999 %) source are reaction sources, adjust the heating temperature of Zn source to 300 ℃, and the heating temperature of Mg source to 360 ℃ 1. The Be source was heated to 910 °C, and a ZnMgBeO film was grown on a ZnO single crystal substrate. The growth time was 2 hours, and the film thickness was about 300 nm.

[0024] The prepared ZnMgBeO film has no defect peaks and has good optical properties; the background electron concentration is as low as 3×10 16 cm -3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com