Full waveband infrared focal plane array based on MEMS technology

An infrared focal plane, full-band technology, applied in microstructure technology, technology for producing decorative surface effects, decorative arts, etc., can solve the problems of reduced detector sensitivity, loss of infrared energy, etc., to improve the absorption rate of infrared energy , the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

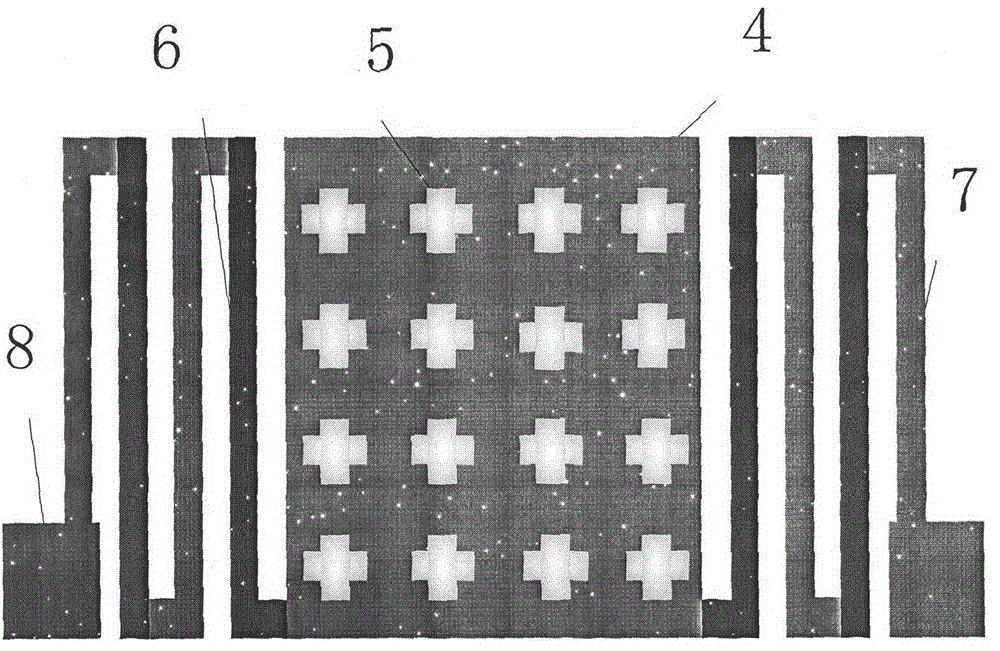

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the structure and method of the present invention will be described in detail below with reference to the accompanying drawings.

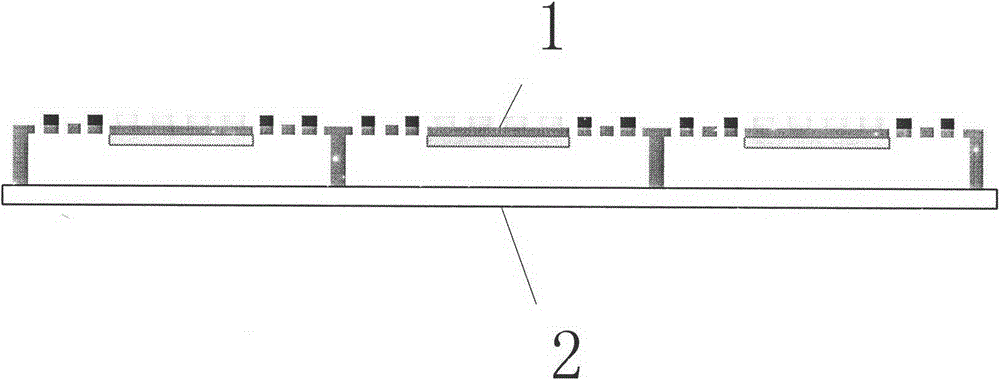

[0041] A MEMS infrared detection focal plane array, which includes a plurality of micro-cantilever beam elements (1) and a substrate (2) supporting a plurality of micro-cantilever beam elements, the substrate (2) supporting a plurality of micro-cantilever beam elements is glass , quartz sheet and other transparent materials, the substrate material has high transmittance to visible light, so that optical readout can be performed from the substrate side, so that infrared rays can directly radiate to the infrared sensitive surface without passing through the substrate, thereby improving the infrared focal plane Array sensitivity.

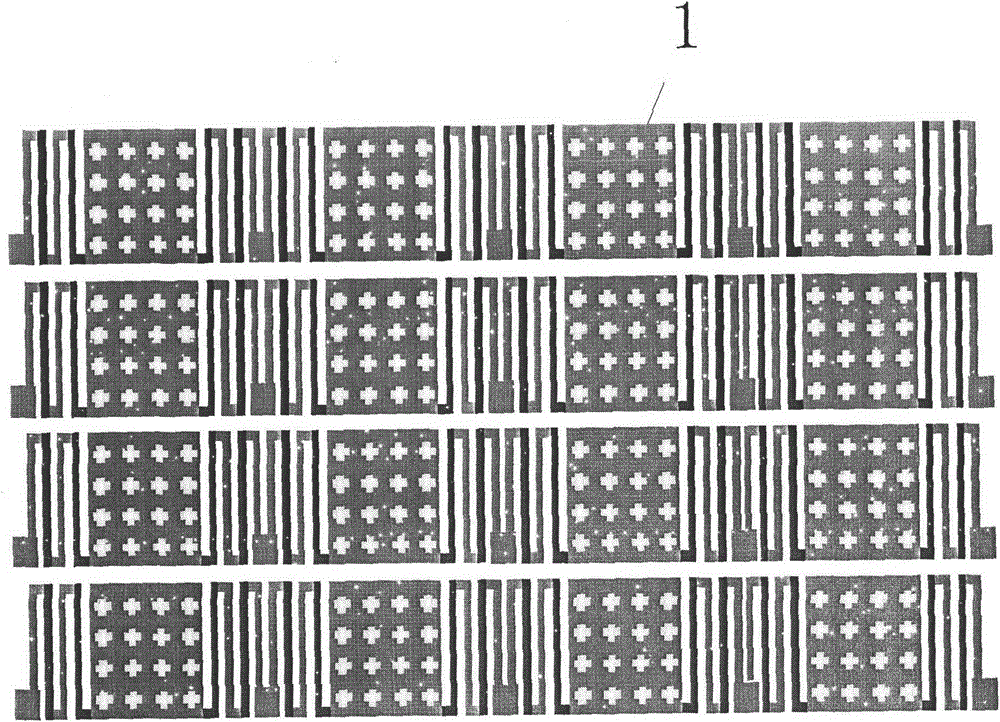

[0042] The number of micro-cantilever beam units (1) can be 64×64, 128×128, 256×256, 512×512 or 1024×1024, etc., and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com