Method for joint measurement of calcium-barium content of silicon-barium alloy by using compleximetry

A silicon-barium alloy, complexometric titration technology, applied in the field of analytical chemistry, can solve the problems of shortening operation steps and operation time, adding many types of medicines, and complicated operation, so as to reduce energy consumption, reduce the types and amounts of additions, shorten the The effect of operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] 1. Method summary:

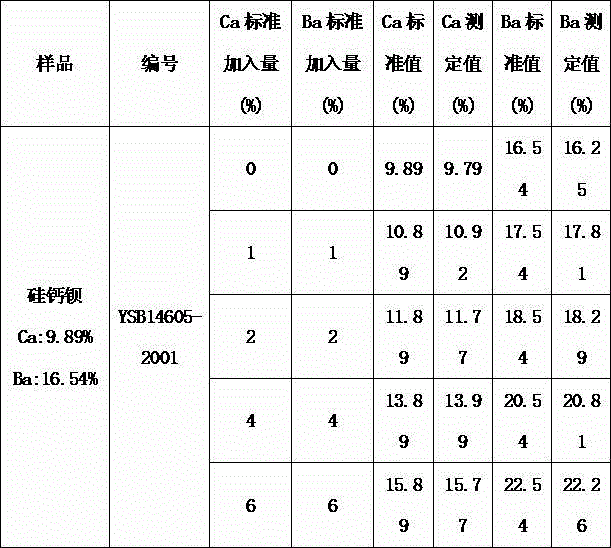

[0024] Take a silicon-barium alloy sample, dissolve the sample with nitric acid-hydrofluoric acid, smoke with perchloric acid, dissolve the salt with hydrochloric acid, divide part of the sample with water, add masking agent to eliminate interfering elements, and use EDTA as the standard The solution was titrated to measure the content of calcium-barium and calcium respectively. The barium content was calculated by subtraction.

[0025] 2. Reagents:

[0026] Nitric acid (density 1.42 g / mL)

[0027] Hydrofluoric acid: (density 1.15g / mL)

[0028] Perchloric acid: (density 1.67g / mL);

[0029] Hydrochloric acid: (hydrochloric acid with a density of 1.19g / mL is mixed with an equal volume of water);

[0030] Triethanolamine solution: (the volume ratio of triethanolamine to water is 1:4);

[0031] Hydroxylamine hydrochloride (solid);

[0032] Ammonia water (mixture of ammonia water with a density of 0.90g / mL and an equal volume of water);

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com