A kind of solid target sheet for spallation neutron source and preparation method thereof

A spallation neutron source and solid target technology, applied in the field of metal welding, can solve the problems of low connection strength between tantalum coating and tungsten, the welding cannot meet the requirements, the tantalum coating is not dense enough, etc., so as to enhance the anti-erosion corrosion performance. , Improve life, the effect of tantalum coating densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

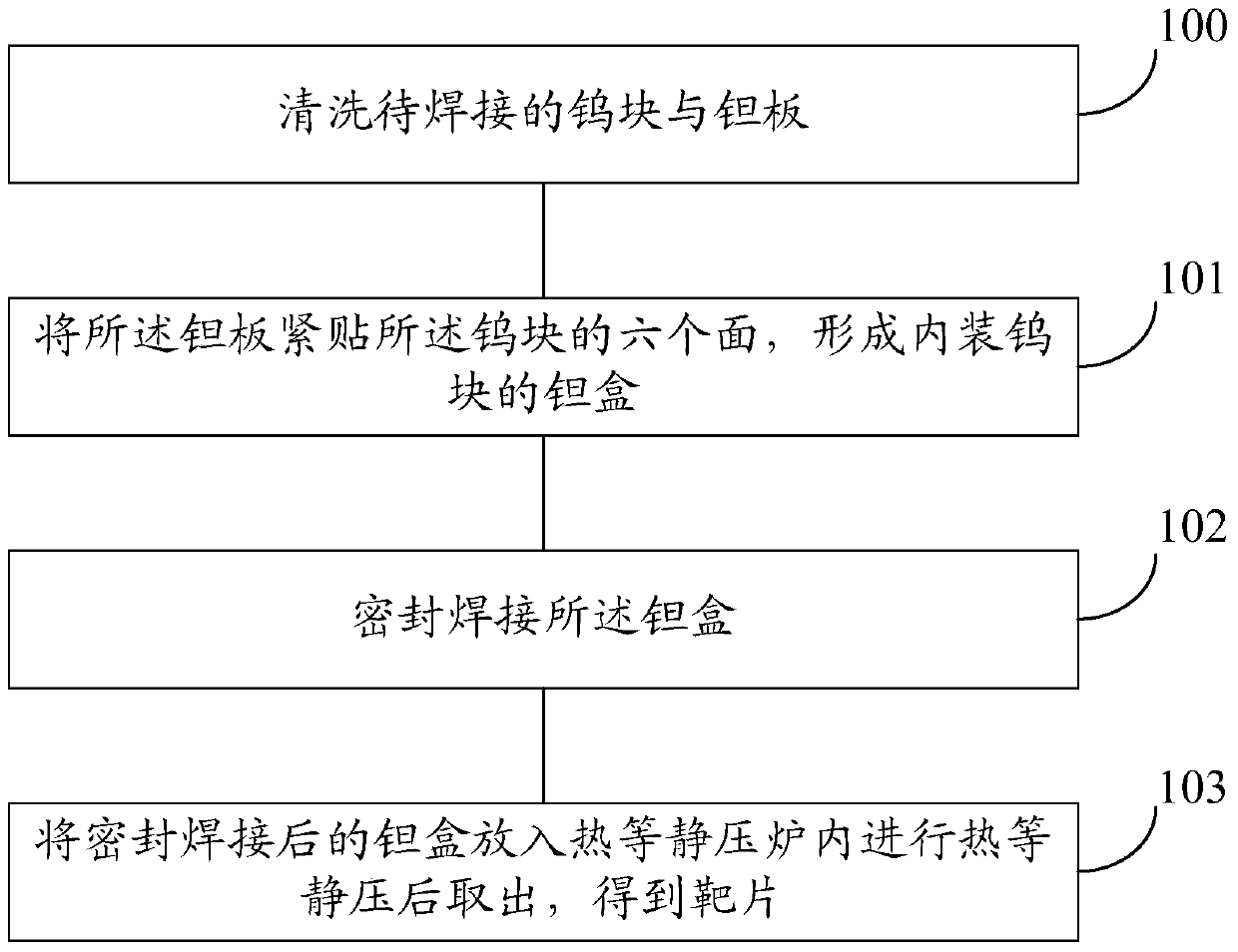

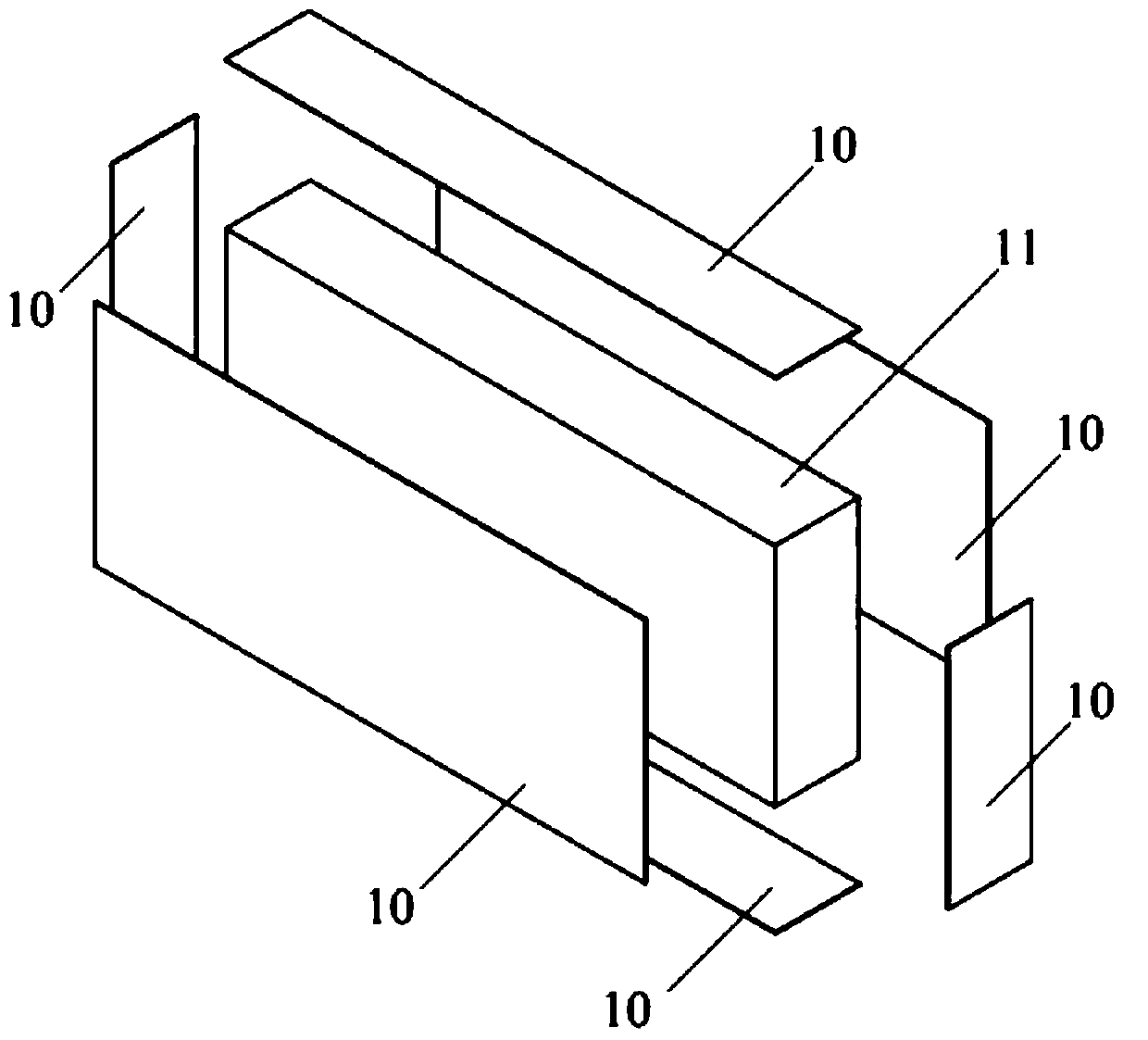

[0021] refer to figure 1 , is a flowchart of a method for preparing a solid target for a spallation neutron source provided by an embodiment of the present invention, and this embodiment may specifically include the following steps:

[0022] Step 100, cleaning the tungsten block and the tantalum plate to be welded. Before welding, the surface of the tungsten block and tantalum plate to be welded is cleaned, the purpose is to make the surface of the tungsten block and tantalum plate clean and ready for subsequent welding. Keeping the surface of the tungsten block and tantalum plate to be welded clean can improve the welding quality and make the tungsten block and tantalum plate fit better after welding.

[0023] In a preferred embodiment of the present invention, the surfaces of the tungsten block and the tantalum plate to be welded can be cleaned with a weak acid, and then ultrasonicated with acetone again after cleaning, and then dried.

[0024] In a preferred embodiment of...

Embodiment 2

[0037] refer to Figure 4 , is a flowchart of a method for preparing a solid target for a spallation neutron source provided by an embodiment of the present invention, and this embodiment may specifically include the following steps:

[0038] Step 200, select a tungsten block with a size of 170*70*25mm, a density of 18.7g / cm3 and a polished surface after being sintered and forged, as the tungsten block to be welded.

[0039]Step 201 , according to the size of each surface of the tungsten block to be welded, six high-purity tantalum plates with a thickness of 0.4-2 mm are processed as the tantalum plates to be welded. It should be noted that the thinner the thickness of the tantalum plate, the smaller the afterheat. Therefore, if the processing conditions permit, the thinner tantalum plate can be processed as much as possible.

[0040] Step 202, cleaning the surface of the tungsten block and the tantalum plate with weak acid, cleaning and drying. The purpose of this step is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com