Laser cladding nickel-based alloy powder for repairing damaged blower blades and its repairing method

A laser cladding, nickel-based alloy technology, applied in the field of surface engineering and remanufacturing, mechanical equipment surface remanufacturing, can solve the problems of cladding layer cracks, difficult to meet complex working conditions, low surface flatness of the cladding layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

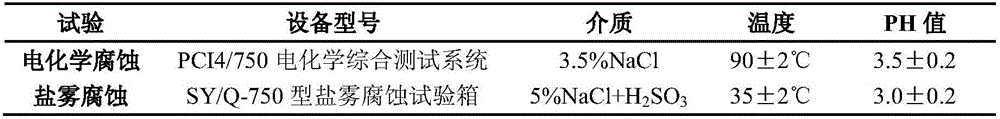

[0032] The composition and mass percentage of the Ni-based alloy powder in this embodiment are: 12.0% Cr, 40% Ni, 1.0% W, 3.0% Mo, 40.0% Fe, 4.0% Co. The power P of the laser cladding machine is 3.0KW, the spot diameter D is 3.0mm, the scanning speed VS is 3.0mm / s, and the powder feeding speed Vf is 10g / min.

[0033] After the laser cladding is completed, the surface of the cladding layer of the sample is bright, without cracks, and has good flatness. The phase of the material is austenite as the main phase, ferrite as the auxiliary phase, and the fiber structure is fine dendrites, which are well developed; the hardness is 515~530HV; impact energy Ak at room temperature V Ak of 10.6J at 600°C V is 12.7J; the electrochemical test corrosion potential and corrosion current are 0.172V and 2.32×10 - 7 A / cm 3 ; Under the salt spray corrosion environment, the time for the substrate and the cladding layer to appear rust spots is 72h and 162h, respectively. The comparison shows t...

Embodiment 2

[0035]The composition and mass percentage of the Ni-based alloy powder in this embodiment are: 15.5% Cr, 45.0% Ni, 1.5% W, 4.0% Mo, 32.0% Fe, 2.0% Co. The power P of the laser cladding machine is 3.5KW, the spot diameter D is 4.0mm, the scanning speed VS is 3.5mm / s, and the powder feeding speed Vf is 8g / min.

[0036] After the laser cladding is completed, the surface of the cladding layer of the sample is bright, without cracks, and has good flatness. The phase of the material is austenite as the main phase, ferrite as the auxiliary phase, and the fiber structure is fine dendrites, which are well developed; the hardness is 520~535HV; impact work Ak at room temperature V Ak of 15.6J at 600°C V is 16.4J; the electrochemical test corrosion potential and corrosion current are -0.0468V and 2.83×10 -7 A / cm 3 ; Under the salt spray corrosion environment, the time for the substrate and the cladding layer to appear rust spots is 72h and 171h, respectively. The comparison shows tha...

Embodiment 3

[0038] The composition and mass percentage of the Ni-based alloy powder in this embodiment are: 18.0% Cr, 47.0% Ni, 1.0% W, 2.0% Mo, 30.0% Fe, 2.0% Co. The power P of the laser cladding machine is 2.5KW, the spot diameter D is 3.0mm, the scanning speed VS is 5.0mm / s, and the powder feeding speed Vf is 11g / min.

[0039] After the laser cladding is completed, the surface of the cladding layer of the sample is bright, without cracks, and has good flatness. The phase of the material is austenite as the main phase, ferrite as the auxiliary phase, and the fiber structure is fine dendrites, which are well developed; the hardness is 510~532HV; impact energy Ak at room temperature V Ak of 12.7J at 450°C V is 13.5J; the electrochemical test corrosion potential and corrosion current are 0.0514V and 2.56×10 -7 A / cm 3 ; Under the salt spray corrosion environment, the time for the substrate and the cladding layer to appear rust spots is 72h and 165h, respectively. The comparison shows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com