Nd<3+> doped (Y1-xScx)2O3 laser transparent ceramic and preparation method thereof

A technology of laser transparent and transparent ceramics, applied in the field of ceramic materials and their preparation process, solid laser ceramic materials and their preparation process, can solve the problems of staying, reporting, and no ceramic materials, etc., and achieve low manufacturing cost and low sintering temperature , Conducive to the effect of industrial scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

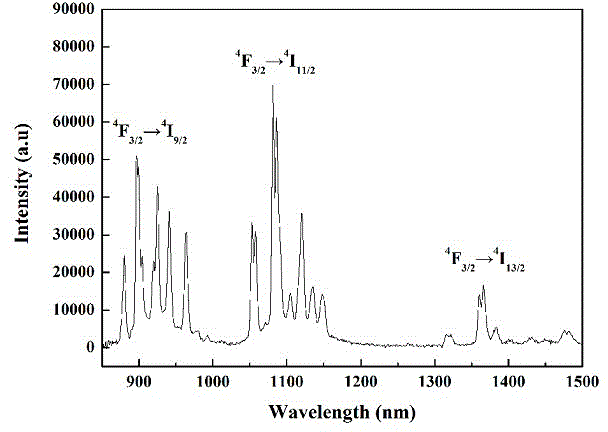

Image

Examples

Embodiment 1

[0022] In this example, a Nd 3+ Doping (Y 1-x sc x ) 2 o 3 The preparation method of laser transparent ceramics comprises the following steps:

[0023] a. Using high-purity Nd with a weight percentage content of 99.99% 2 o 3 , Y with a weight percentage content of 99.99% 2 o 3 and 99.99% Sc by weight 2 o 3 The nanopowder as raw material, with Y 2 o 3 and Sc 2 o 3 as the matrix material, with Nd 2 o 3 It is a doping material, and the doping amount is calculated by mole percentage. The molar ratio of each raw material component is as follows: Nd2 o 3 1.0 at.%, Y 2 o 3 49.5 at.%, Sc 2 o 3 49.5at.%;

[0024] b. Stir the base material and the dopant material prepared according to the formula in step a, fully and evenly mix, and carry out wet ball milling in the mixture absolute ethanol for 5 hours;

[0025] c. drying the mixture after ball milling in step b at 90°C, and then pre-burning at 1200°C for 8 hours;

[0026] d. put into the ball mill tank through the...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, especially in that:

[0033] In this example, Nd 3+ Doping (Y 1-x sc x ) 2 o 3 The preparation method of laser transparent ceramics comprises the following steps:

[0034] a. Using high-purity Nd with a weight percentage content of 99.99% 2 o 3 , Y with a weight percentage content of 99.99% 2 o 3 and 99.99% Sc by weight 2 o 3 The nanopowder as raw material, with Y 2 o 3 and Sc 2 o 3 as the matrix material, with Nd 2 o 3 It is a doping material, and the doping amount is calculated by mole percentage. The molar ratio of each raw material component is as follows: Nd 2 o 3 1.0 at.%, Y 2 o 3 99 at.%, Sc 2 o 3 is 0 at.%;

[0035] b. This step is identical with embodiment one;

[0036] c. This step is identical with embodiment one;

[0037] d. This step is the same as in Embodiment 1;

[0038] e. this step is identical with embodiment one;

[0039] f. This step is identical with embodiment one;

...

Embodiment 3

[0042] This embodiment is basically the same as the previous embodiment, and the special features are:

[0043] In this example, Nd 3+ Doping (Y 1-x sc x ) 2 o 3 The preparation method of laser transparent ceramics comprises the following steps:

[0044] a. Using high-purity Nd with a weight percentage content of 99.99% 2 o 3 , Y with a weight percentage content of 99.99% 2 o 3 and 99.99% Sc by weight 2 o 3 The nanopowder as raw material, with Y 2 o 3 and Sc 2 o 3 as the matrix material, with Nd 2 o 3 It is a doping material, and the doping amount is calculated by mole percentage. The molar ratio of each raw material component is as follows: Nd 2 o 3 1.0 at.%, Y 2 o 3 89 at.%, Sc 2 o 3 is 10 at.%;

[0045] b. This step is identical with embodiment one;

[0046] c. This step is identical with embodiment one;

[0047] d. This step is the same as in Embodiment 1;

[0048] e. this step is identical with embodiment one;

[0049] f. This step is identical w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com