Waterproof acrylic acid adhesive tape and preparation method thereof

An acrylic glue, acrylic adhesive technology, applied in the direction of adhesive, N-vinylpyrrolidone copolymer adhesive, adhesive type, etc. sex, improve cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

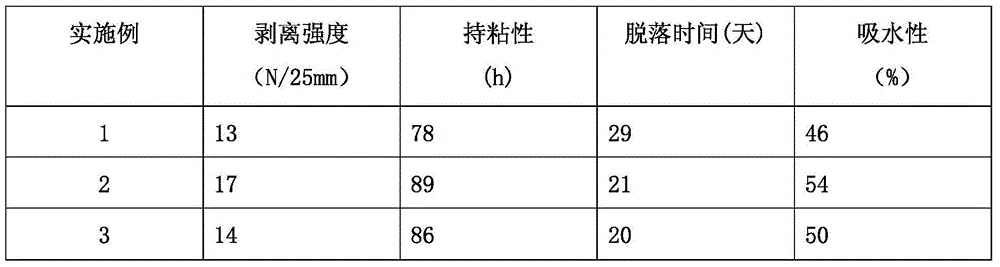

Examples

Embodiment 1

[0038] The waterproof acrylic adhesive tape of the present invention comprises a substrate layer, on which a waterproof acrylic adhesive is coated to form an adhesive layer, and a release material layer is pasted on the other side of the adhesive layer, and the waterproof The acrylic adhesive consists of the following components by weight:

[0039] A component:

[0040] 3 parts paraffin,

[0041] 2 parts of silane coupling agent,

[0042] Butanone 11 parts,

[0043] 2 parts isocyanate,

[0044] 45 parts of methyl methacrylate,

[0045] 40 parts of ethyl acrylate,

[0046] 11 parts of dimethyldiethoxysilane;

[0047] 200 parts of toluene,

[0048] 3 parts resin,

[0049] 2 parts of azo compound,

[0050] Butyl acrylate 20 parts

[0051] Acrylonitrile 11 parts

[0052] Acrylic 9 parts

[0053] Sodium dodecyl sulfonate 2 parts

[0054] Potassium sulfate 2 parts

[0055] 2 parts dodecyl mercaptan

[0056] Ammonia 20 parts

[0057] 20 parts of water

[0058] B comp...

Embodiment 2

[0062] The waterproof acrylic adhesive tape of the present invention comprises a substrate layer, on which a waterproof acrylic adhesive is coated to form an adhesive layer, and a release material layer is pasted on the other side of the adhesive layer, and the waterproof The acrylic adhesive consists of the following components by weight:

[0063] A component:

[0064] 4 parts paraffin,

[0065] 3 parts of silane coupling agent,

[0066] Butanone 12 parts,

[0067] 2.5 parts of isocyanate,

[0068] 47 parts of methyl methacrylate,

[0069] 45 parts of ethyl acrylate,

[0070] 13 parts of dimethyldiethoxysilane;

[0071] 25 parts of toluene,

[0072] 4 parts resin,

[0073] 4 parts of azo compound,

[0074] Butyl acrylate 25 parts

[0075] Acrylonitrile 16 parts

[0076] Acrylic acid 9.5 parts

[0077] Sodium dodecyl sulfate 2.5 parts

[0078] Potassium sulfate 2.5 parts

[0079] 4 parts dodecyl mercaptan

[0080] Ammonia 25 parts

[0081] 30 parts of water

...

Embodiment 3

[0086]The waterproof acrylic adhesive tape of the present invention comprises a substrate layer, on which a waterproof acrylic adhesive is coated to form an adhesive layer, and a release material layer is pasted on the other side of the adhesive layer, and the waterproof The acrylic adhesive consists of the following components by weight:

[0087] A component:

[0088] 6 parts paraffin,

[0089] 5 parts of silane coupling agent,

[0090] Butanone 13 parts,

[0091] 3 parts isocyanate,

[0092] 60 parts of methyl methacrylate,

[0093] 49 parts of ethyl acrylate,

[0094] 15 parts of dimethyldiethoxysilane;

[0095] 30 parts of toluene,

[0096] 5 parts resin,

[0097] 5 parts of azo compounds,

[0098] 30 parts of butyl acrylate

[0099] Acrylonitrile 20 parts

[0100] Acrylic 10 parts

[0101] Sodium dodecyl sulfate 3 parts

[0102] Potassium sulfate 3 parts

[0103] Dodecyl Mercaptan 5 parts

[0104] Ammonia 30 parts

[0105] 40 parts of water

[0106] B com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com