Method for improving yield of pyrolysis coal tar of low-rank coals

A technology of coal tar and low-rank coal, which is applied in the field of improving the yield of low-rank coal pyrolysis coal tar, can solve the problems of unmentioned coal tar and low coal tar yield, shorten the production time and increase the yield rate, increase the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

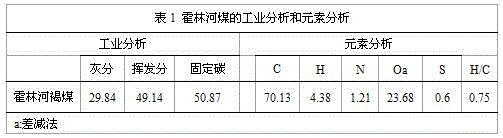

Image

Examples

Embodiment 1

[0022] (1) Raw coal drying treatment: 50g of coal with a particle size of less than 200 meshes is vacuum-dried for 24 hours at a temperature of 80°C and a pressure of 1000Pa to obtain dry coal;

[0023] (2) Swelling treatment: Mix 30g of dry coal obtained in step (1) with a mixed solvent, swell for 0.5 hours at a temperature of 60°C and a pressure of 0.1MPa, then filter and vacuum-dry to obtain swollen coal. Among them, the ratio of the mixed solvent to the coal sample is 2, and the unit is ml / g. The mixed solvent is composed of alcohols and tetrahydrofuran. In the mixed solvent, the volume ratio of alcohols to tetrahydrofuran is 2:1, and the alcohols are methanol:ethanol : A mixture of ethylene glycol with a volume ratio of 1:1:1;

[0024] (3) Pyrolysis reaction: Under the protection of an inert gas, raise the temperature of the tube furnace to 500°C, then push 20 g of the swollen coal obtained in step (2) into the tube furnace for pyrolysis reaction, react for 0.25 hours, an...

Embodiment 2

[0033] (1) Raw coal drying treatment: 50g of coal with a particle size of less than 200 mesh is vacuum-dried for 12 hours at a temperature of 80°C and a pressure of 1000Pa to obtain dry coal;

[0034] (2) Swelling treatment: Mix 30 parts by weight of dry coal obtained in step (1) with a mixed solvent, swell for 0.5 hours at a temperature of 60°C and a pressure of 0.1 MPa, then filter and vacuum-dry to obtain swollen coal, wherein , the ratio of the mixed solvent to the coal sample is 2, the unit is ml / g, the mixed solvent is composed of alcohols and tetrahydrofuran, in the mixed solvent, the volume ratio of alcohols to tetrahydrofuran is 5:1, and the alcohols are methanol:ethanol: A mixture of ethylene glycol with a volume ratio of 1:1:3;

[0035](3) Pyrolysis reaction: Under the protection of an inert gas, raise the temperature of the tube furnace to 500°C, then push 20 g of the swollen coal obtained in step (2) into the tube furnace for pyrolysis reaction, react for 0.25 hou...

Embodiment 3

[0043] (1) Raw coal drying treatment: vacuum-dry coal with a particle size of less than 200 mesh at a temperature of 80°C and a pressure of 100 Pa for 24 hours to obtain dry coal;

[0044] (2) Swelling treatment: Mix 30 parts by weight of dry coal obtained in step (1) with a mixed solvent, swell for 0.5 hours at a temperature of 100°C and a pressure of 1.5 MPa, then filter and vacuum dry to obtain swollen coal, wherein , the ratio of the mixed solvent to the coal sample is 10, the unit is ml / g, the mixed solvent is composed of alcohols and tetrahydrofuran, in the mixed solvent, the volume ratio of alcohols to tetrahydrofuran is 8:1, and the alcohols are methanol:ethanol: A mixture of ethylene glycol with a volume ratio of 1:2:5;

[0045] (3) Pyrolysis reaction: Under the protection of inert gas, the temperature of the tube furnace was raised to 600 ° C, and then 20 g of swollen coal was pushed into the tube furnace for pyrolysis reaction. Quickly remove and cool to within 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com