Preparation method of flexible electrode material

A flexible electrode, flexible technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high synthesis cost, poor cycle stability, and large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of vanadyl acetylacetonate / carbon cloth composite flexible electrode material

[0020] First, ultrasonicate the carbon cloth in ethanol for about 30 minutes, add vanadyl acetylacetonate into the porcelain boat, put the carbon cloth on top of the porcelain boat, cover another porcelain boat to seal it, and keep it warm in the air at 250-400°C for 2-6 hours. After cooling, the vanadium pentoxide electrode material supported by carbon cloth is obtained.

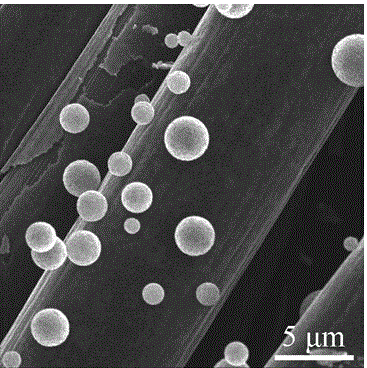

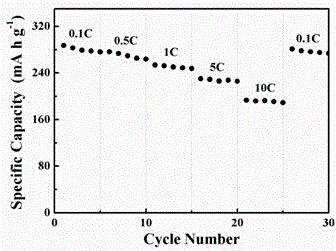

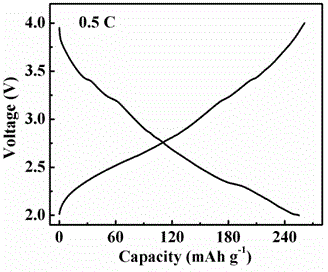

[0021] Morphology and performance tests of the prepared carbon cloth supported vanadium pentoxide electrode material.

[0022] The morphology of the obtained composite material was characterized by a scanning electron microscope (SEM, Philips-XL-30FEG), with metal lithium as the auxiliary electrode and reference electrode, containing 1M / LLiPF 6 A mixed solution of ethylene carbonate (EC) and ethyl methyl carbonate (EMC) was used as the electrolyte, where EC:EMC=1:1, and the battery was assembled in an argon-f...

Embodiment 2

[0024] Preparation of flexible electrode materials composed of vanadium acetylacetonate / carbon cloth

[0025] First, ultrasonicate the carbon cloth in ethanol for about 30 minutes, add vanadium acetylacetonate into the porcelain boat, put the carbon cloth on top of the porcelain boat, cover another porcelain boat to seal it, keep it warm in the air at 250-400°C for 2-6 hours, and cool That is, the vanadium pentoxide electrode material supported by carbon cloth is obtained.

Embodiment 3

[0027] Preparation of iron acetylacetonate / carbon cloth composite flexible electrode materials

[0028] First, ultrasonicate the carbon cloth in ethanol for about 30 minutes, add ferrovanadium acetylacetonate into the porcelain boat, put the carbon cloth on the top of the porcelain boat, cover another porcelain boat to seal it, and keep it warm in the air at 250-400°C for 2-6 hours. After cooling, the ferric oxide electrode material supported by carbon cloth can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com