Positive electrode lead plaster of lead acid storage battery

A lead-acid battery, positive lead paste technology, applied in lead-acid batteries, battery electrodes, circuits, etc., can solve the problems of unstable ionic liquid properties, decomposition and oxidation, etc., to improve curing efficiency, high dispersion, and inhibit loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Positive electrode paste formula, by weight percentage, consists of the following components: Shimadzu type lead powder 75%, lead oxide 5%, chemical fiber 0.1%, 1-ethyl-3-methylimidazole trifluoromethanesulfonate salt ([Emim]OTf) 0.1%, graphite 0.1%, high-purity water 10%, weight concentration of 50% sulfuric acid 9.7%.

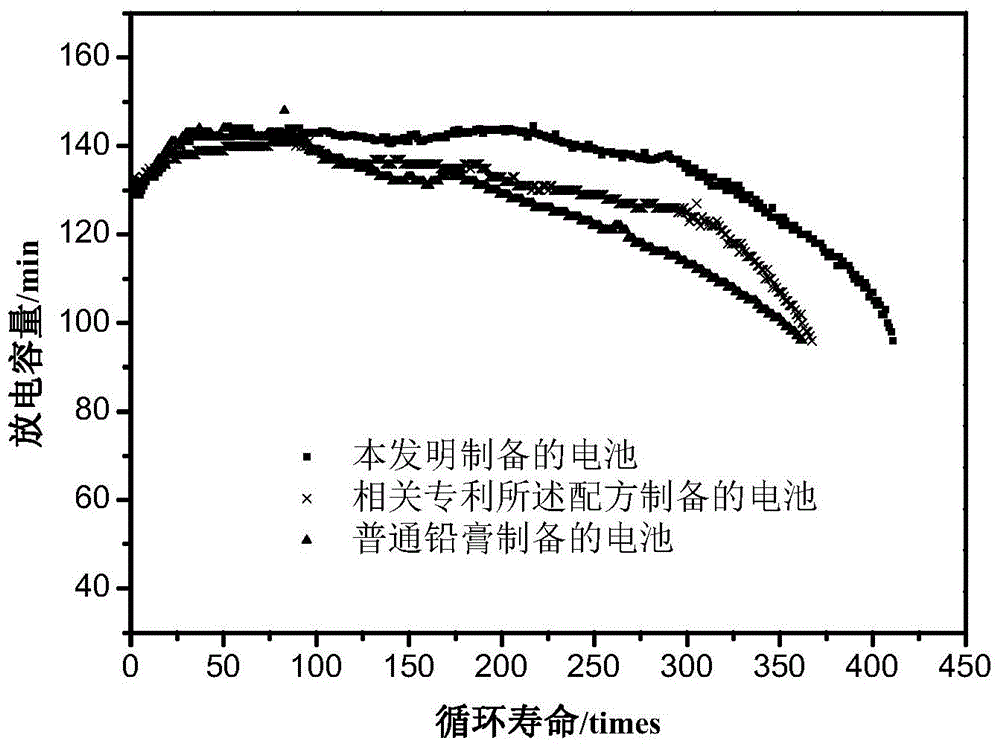

[0029] According to the above formula and paste, accumulators were made according to the existing process, with no addition of 1-ethyl-3-methylimidazole triflate as a blank control, and the lead paste disclosed in Example 1 of CN102610823A as a comparative example . According to the traditional method of cycle life test, the results are as follows figure 1 Shown:

[0030] After 200 times of charge and discharge, the discharge time of the storage battery made of the lead paste of the present invention is obviously higher than that of the blank control and the comparative example. The life of the blank control and the comparative example is terminated...

Embodiment 2

[0032] Positive lead paste formula, by weight percentage, consists of the following components: Shimadzu type lead powder 85%, lead oxide 1%, chemical fiber 0.05%, 1-octyl-3-methylimidazole trifluoromethanesulfonate Salt ([Omim]OTf) 0.4%, graphite 0.5%, high-purity water 7%, weight concentration 6.05% of sulfuric acid 40-50%.

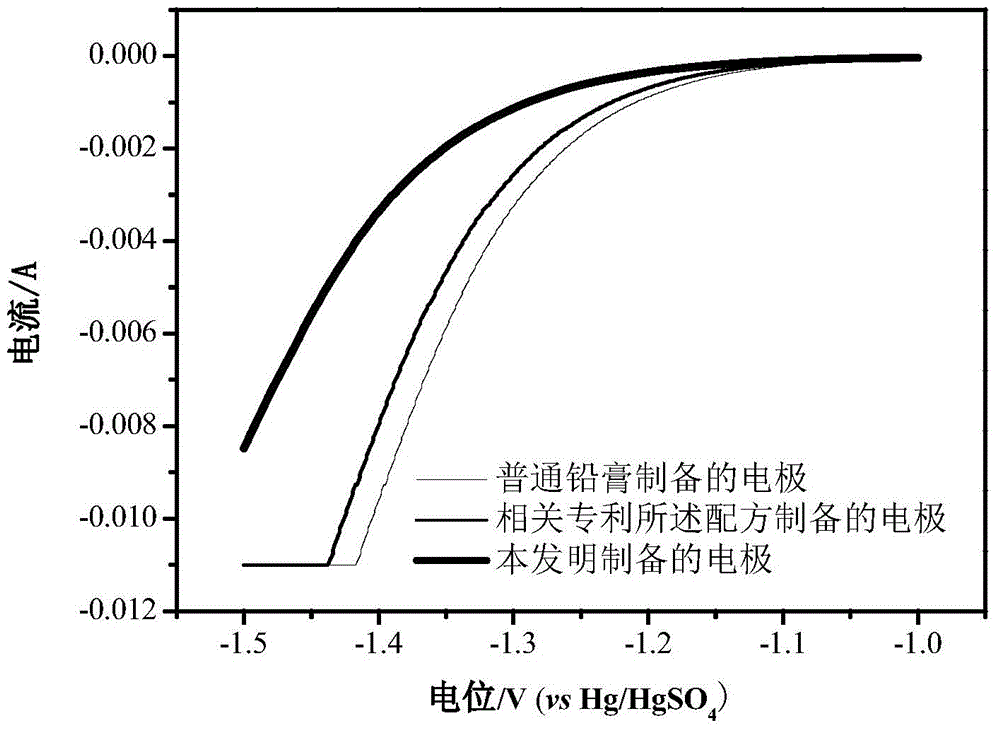

[0033] According to the above formula and paste, then make a microelectrode according to the traditional method, without adding 1-ethyl-3-methylimidazole trifluoromethanesulfonate as a blank control, and take the lead paste disclosed in Example 1 of CN102610823A as a comparative example . Using a three-electrode system to test the overpotential of hydrogen evolution and oxygen evolution, the results are as follows figure 2 Shown:

[0034] Compared with the blank control and the contrast ratio, the hydrogen evolution and oxygen evolution overpotential of the microelectrode made by the lead paste of Example 2 is significantly improved. Although the con...

Embodiment 3

[0036] Positive electrode paste formula, by weight percentage, consists of the following components: Shimadzu type lead powder 80%, lead oxide 2.5%, chemical fiber 0.1%, 1-butyl-3-methylimidazole trifluoromethanesulfonic acid 0.2% of salt ([Bmim]OTf), 0.2% of graphite, 9% of high-purity water, and 8% of sulfuric acid with a weight concentration of 40-50%.

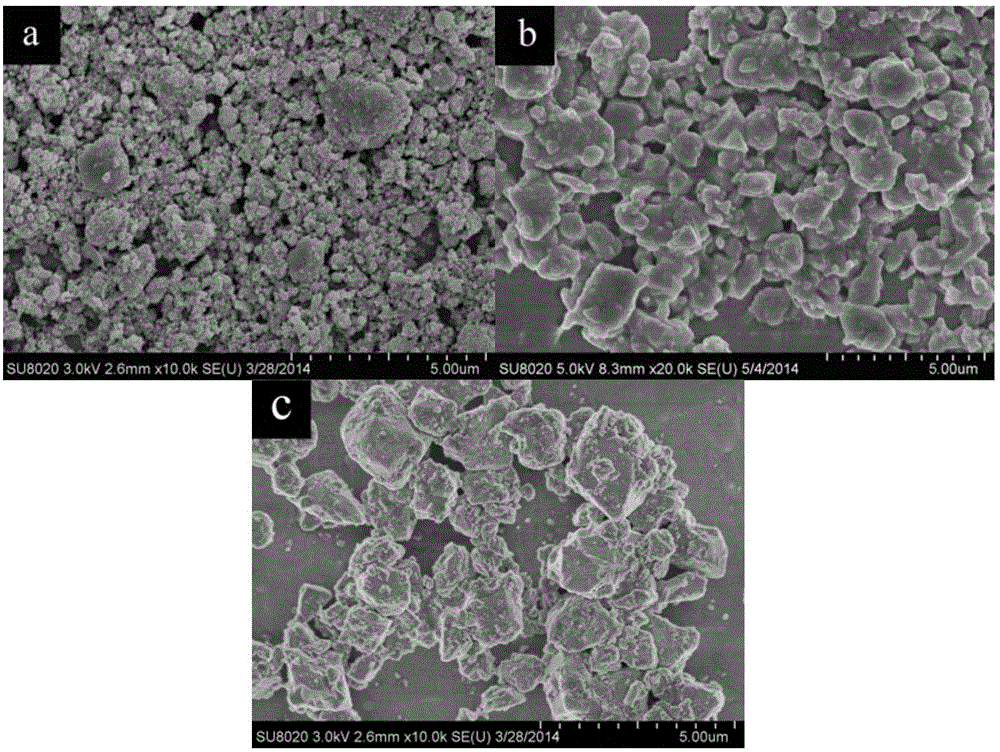

[0037] According to the above formula and paste, and then assembled into a battery according to the traditional process, no addition of 1-ethyl-3-methylimidazolium triflate was used as a blank control, and the lead paste disclosed in Example 1 of CN102610823A was used as a comparative example. After the battery has been used for a period of time, the lead paste on the plate is taken out for scanning electron microscope testing, and the results are as follows: image 3 Shown:

[0038] The active material of the present invention maintains better porous structure and crystal form, and the formed lead sulfate crystals are sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com